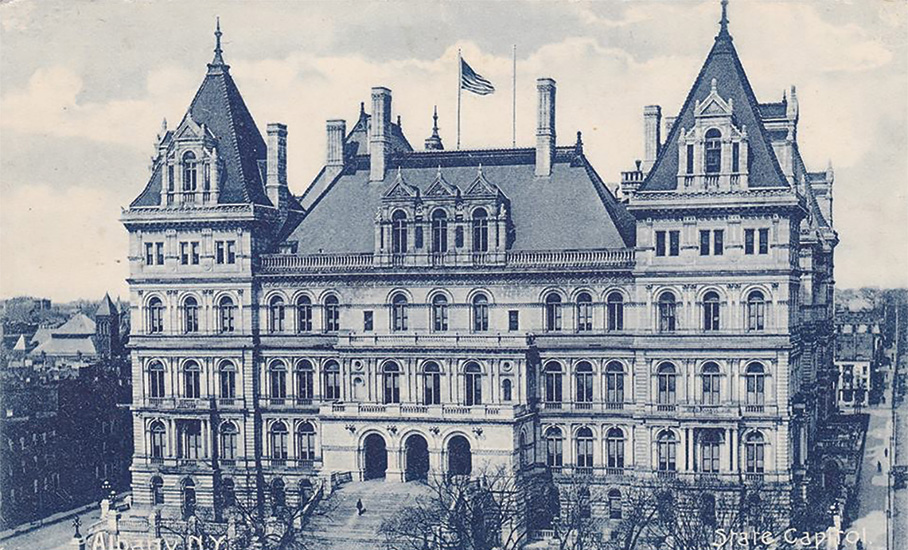

Built between 1867-1899, the New York State Capitol is a significant U.S. architectural landmark recognized for its masonry construction that blends Renaissance, Romanesque and French Renaissance Revival architecture. The view of the eastern staircase from State Street is iconic for New York residents and tourists. It showcases the seat of state government and has been the setting for many memorable moments at the capitol, including President Richard Nixon’s speech while visiting Albany in 1969.

During the past century, water infiltration caused the 77-step staircase to deteriorate to such an extent it has been barricaded from public use for the past 10 years. The New York State Office of General Services initiated a significant $72 million project to renovate the capitol’s Eastern Approach. The massive project currently is underway and includes reconstructing the staircase and promenades on two sides of the capitol, reconstructing retaining walls, installing storm drainage systems, new window and door fittings, and new weatherproofing systems. The project combines modern and traditional construction techniques while reusing existing materials where possible.

Greenwood Industries, Worcester, Mass., was selected as the roofing contractor for the project to restore New York State Capitol’s courtyard roof areas.

Replacing a century-old roof

New York State Capitol’s courtyard deck waterproofing system also serves as the roof over mechanical and electrical equipment that helps keep power, heat and hot water operating in the building. The courtyard includes an attached restaurant infill and a copper-clad covered walkway called Hawk Street Passage that serves as a pedestrian corridor.

Persistent leaks in the waterproofing membrane compromised equipment below, and deterioration of standing-seam copper panels on the passageway roof prompted full replacements of the capitol’s open-air courtyard deck waterproofing system and coppper panel roof areas.

Greenwood Industries’ restoration work began in July 2022. From the 6,600-square-foot plaza deck area over the equipment, the team removed multiple layers (14 inches thick) of waterproofing materials including EPDM membrane down to the existing brick vaults. To access the courtyard, materials were transported through the building and then through an overhead door.

Crew members then poured a base layer of lightweight insulating concrete over the existing brick construction followed by Siplast® Paraflex Liquid Membrane. Malden bluestone and granite pavers were installed over the waterproofing system in the public areas of a newly designated occupied outdoor space, honoring the intent of the original 19th century design while receiving an updated look designed by Bell & Spina Architects, Syracuse, N.Y.

Large limestone planters with zinc-tin-coated copper caps containing drought-tolerant native plants also were installed to enhance the courtyard’s visual appearance while concealing ventilation components for the basement space.

The Hawk Street Passage and restaurant received structural reinforcing and insulation upgrades, but the original copper reached the end of its service life and no longer could be repaired.

Copper work

Greenwood Industries craftsmen removed and replaced all the original copper on the 4,000-square-foot Hawk Street Passage roof including flat- and standing-seam panels, wall cladding, downspouts, intricate ornate rosettes, egg and dart trim (classic architectural motif), and ornamental scrollwork integrated into the wall panels and new windows. Many pieces were fabricated in the company’s off-site facility.

The team matched the original, historical profiles with careful fabrication and detailing of the individual pieces including application of Carlisle® WIP® 300HT self-adhering roof underlayment.

“The original intent was to hand-solder the joinery,” says Kristian Hoffman, project manager at Greenwood Industries. “However, after constructing and reworking a 1:1 scale mockup of a typical wall panel and window, we developed alternative attachment details using hidden clips, rivets and bolts to avoid visible fasteners. This meant every piece would fit together meticulously like a puzzle, giving the structure a beautiful, seamless look.”

More than 6 tons of copper were used for the roof and wall cladding and ornamentation installed on the passageway and restaurant.

Beautifully executed

In March 2024, the Greenwood Industries team completed work on the New York State Capitol with no safety incidents or injuries. The Eastern Approach is expected to be renovated by May 2029.

When construction began on the New York State Capitol in 1867, electric lighting did not exist. By the 1880s, it was one of the first buildings in the U.S. to have electricity. Thousands of stones were used to construct the building, and they were all hand-cut and hand-carved. Hundreds of stone cutters and carvers were employed, most of them coming from England, Ireland, Scotland and Wales.

The building’s exterior is constructed from white granite, which was difficult to carve because it was harder than the steel tools used by the carvers. Nevertheless, the capitol stone carvers managed to carve 77 famous faces onto the exterior, including Abraham Lincoln, Walt Whitman and Susan B. Anthony. The New York State Capitol was listed on the National Register of Historic Places in 1971 and was designated a National Historic Landmark in 1979.

Greenwood Industries’ meticulous attention to detail and craftsmanship transformed New York State Capitol’s courtyard from an inaccessible space to an attractive, functional area while maintaining the building’s original design.

New York State Capitol’s monumental staircase was completed in 1897 and is one of the capitol’s most famous features, renowned for its elaborate carvings and design. To reconstruct the steps, the entire staircase was disassembled, each piece catalogued and then put back together. Click here to watch a video.

“As the architect of record, our firm worked with Greenwood Industries’ talented and skilled carpenters, roofing workers and sheet-metal craftsmen to restore and upgrade the ornamental copper wall paneling, moldings and trim, standing-seam and soldered flat-seam copper paneling, and waterproofing over the roof of the courtyard,” says Douglas Arena, AIA, RRC, principal for Bell & Spina Architects. “We were impressed with their attention to detail and commitment to the restoration process, including working with our team to develop innovative copper fabrication details. The completed work is beautifully executed and will endure for decades.”

From waterproofing system and paver installation to restoring ornamental copper elements on Hawk Street Passage, the Greenwood Industries team’s dedication to excellence shows. For its work on the New York State Capitol, Greenwood Industries received a 2025 NRCA Gold Circle Awards honorable mention in the steep-slope category. The renovation project also won an Engineering News-Record Merit Award and a North American Copper in Architecture Award.

“What made this project truly rewarding was watching hard work turn into something real and lasting,” Hoffman says. “The best part was stepping back at the end and knowing Greenwood Industries played a major role in shaping every detail. Bringing together teams from New York, Connecticut, Massachusetts and Rhode Island to work toward a shared goal—and achieve it efficiently—was incredible.”

Project name: New York State Capitol Courtyard

Project location: Albany, N.Y.

Project duration: July 2022-March 2024

Roofing contractor: Greenwood Industries, Worcester, N.Y.

General contractor: VMJR Companies, Glens Falls, N.Y.

Waterproofing and roof system types: Liquid monolithic membrane and copper

Waterproofing and roofing manufacturers: Carlisle® Construction Materials, Carlisle, Pa.; Siplast,® Dallas

CHRYSTINE ELLE HANUS

Professional Roofing’s associate editor

Director of commmunications

NRCA