There are many reasons to conduct roof moisture surveys. Moisture meters such as infrared thermal imaging, nuclear gauges, electrical impedance (capacitance) and resistance-pin-type moisture meters are necessary tools for such forensic work. However, using the technology without following appropriate standards can result in false positives.

For example, ASTM D7954, “Standard Practice for Moisture Surveying of Roofing and Waterproofing Systems Using Non-Destructive Electrical Impedance Scanners,” states pin moisture meters can be used for a quick assessment, but the pin moisture meter reading needs to be correlated to a gravimetric analysis for an accurate, reliable reading.

False positives and inaccurate readings can lead to unnecessarily removing roofing materials, a costly mistake for building owners, roofing contractors and insurance companies. If you or your consultant use moisture meters, be sure to follow the appropriate standards to provide accurate measurements.

Background

In addition to ASTM D7954, the standards for roof moisture surveys include ASTM C1153, “Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging”; ANSI/SPRI/IIBEC NT-1 2017 (R2022), “Detection and Location of Latent Moisture in Building Roofing Systems by Nuclear Radioisotopic Thermalization”; and ASTM D7438, “Standard Practice for Field Calibration and Application of Hand-Held Moisture Meters.”

All materials used to construct a roof system contain hydrogen or moisture. According to The NRCA Roofing Manual: Architectural Metal Flashing and Condensation and Air Leakage Control—2022, roofs have a “normal ambient moisture” content range. This range increases and decreases, reflecting the current relative humidity surrounding roofing materials.

All roof system components, such as insulation, underlayment and cover boards, also have their own range of acceptable moisture. Equilibrium moisture content and moisture capacity varies for select roof insulation and deck materials.

Another issue affecting moisture content is vapor drive. During winter months, the dew point (condensation) is near the top of a roof at the membrane and top facer bond, but during summer months, it reverses and is at the bottom near the roof deck. For example, this condensation is usually a thin layer of moisture that can cause the pin moisture meter to read wet when the paper facer is not actually fully saturated.

These issues can affect most methods for assessing moisture in a roof system and, if not taken into consideration, can lead to errors when interpreting the readings provided by a moisture analysis method. This can create false positives and costly mistakes.

Basics of roof moisture surveys

There are a number of tools that measure moisture in a roof system.

Infrared gauges

During the day, the sun radiates energy onto a roof. During the night, areas of the roof that are wet retain the heat longer than the dry areas. Infrared tools can detect this heat and “see” the warmer, potentially wet areas during periods of uneven heat dissipation. It is important to note infrared imagers do not see moisture; they see temperature differences.

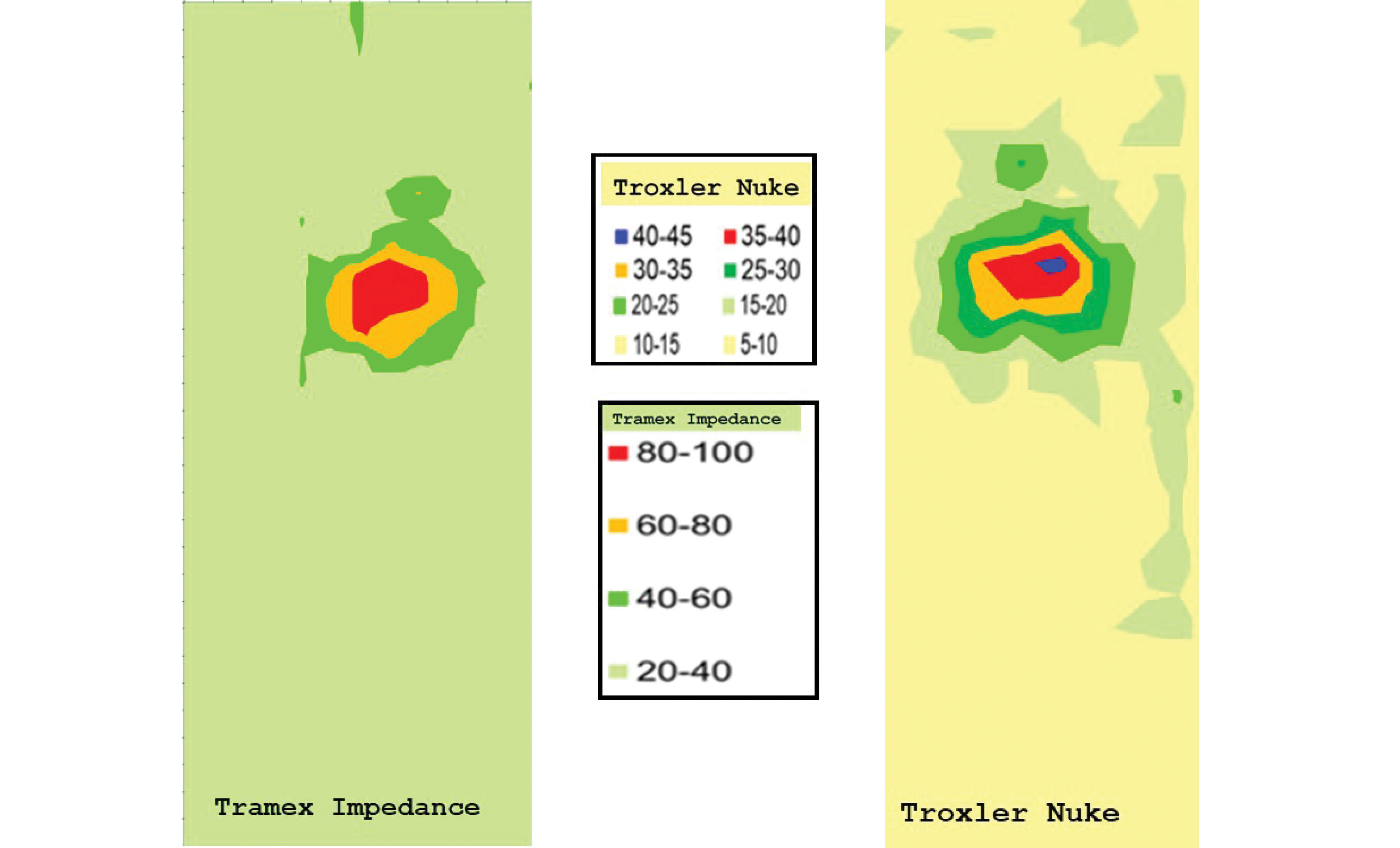

The photo shows a nighttime infrared scan. The lighter-colored areas show high-moisture content. Figure 1 shows noninvasive moisture meters—a Tramex impedance gauge and a Troxler® nuclear gauge to confirm moisture using a 5- by 5-foot grid. The infrared standard, ASTM C1153, requires verification of anomalies to confirm areas of moisture.

According to ASTM C1153, verification of infrared data must be carried out by one of the following invasive test methods: cores (cutting out small sections of the roof) or a combination of cores and moisture meter probes. Noninvasive testing equipment such as nuclear and capacitance meters may be used to complement but not replace invasive verification.

When an anomaly is identified as potential moisture, an effort to verify the moisture should be made using either noninvasive nuclear gauges (Troxler) or impedance gauges (Tramex) followed by invasive verification using moisture meter probes and core tests.

Nuclear gauges

ANSI/SPRI/IIBEC NT-1 2017 (R2022) provides a minimum set of procedures for conducting surveys of moisture in membrane roof systems and analyzing the data obtained. According to Section 3.6.1 in Moisture Detection, “Fast neutrons from the radioactive source enter the material being surveyed and are both scattered and slowed down by collision with the nuclei of the atoms composing the material.”

Typically, the roof area to be surveyed is laid out with a grid based upon X and Y coordinates that are 5 to 10 feet apart. A baseline low reading is found and then higher readings are identified for core locations. Typically, cores are taken at low, middle and high readings but not the highest readings.

In Section 6.0—Verification and Quantification, the standard states the field data (nuclear readings) is only “relative” and “shall” be quantified by core cuts. These cores would then be analyzed for moisture content by weight or gravimetric analysis. Gravimetrics is determined by moisture content by weight and is calculated using the following formula: [(wet weight-dry weight)/dry weight] x 100.

There is no way to use the Equilibrium Moisture Content Tables on pages 10 and 11 of ANSI/SPRI/IIBEC NT-1 2017 (R2022) without conducting gravimetric analysis. To correctly follow the standard for accurate results, quantification of moisture by gravimetric moisture analysis must be conducted when using nuclear gauges for roof moisture surveys. The same is true for impedance gauges.

Impedance gauges

Impedance gauges use nondestructive electrical scanners to locate moisture and evaluate the comparative moisture content within insulated low-slope roof systems. ASTM D7954 discusses the method to verify the data and the scanning techniques, which involved a grid system on an X-Y axis, similar to the nuclear standard, and a continuous systematic scanning system. The impedance scanner must be calibrated to the area of the roof being scanned.

This is the area where errors in moisture assessment can occur; following the standard closely will help minimize errors.

First, it is important to properly calibrate the scanner. According to ASTM D7954, Section 9.2.2-Preparation, “Cores taken shall be retained for gravimetric analysis for the verification stage.” It is important to note readings obtained by a resistance-pin-type moisture meter to evaluate moisture conditions of core samples are “relative” and, typically, need to be “correlated” with the moisture content value at the verification stage.

In Section 11.3.7-Other Moisture, testing equipment such as nuclear meters, infrared equipment, handheld nondestructive impedance meters or pin-type resistance meters are useful to complement impedance readings, but they “shall not replace” core sampling for quantitative verification of results. It is permitted to check the insulation material of each core specimen immediately after extraction from the roof system to provide a quick indication of its moisture condition with a pin-type resistance moisture meter. The pin-type resistance meter readings should be recorded so they can be correlated with moisture content measurements obtained by gravimetric analysis at the verification stage of the procedure.

As mentioned in Annex A1-Impedance Test Method, A1.4.11, nondestructive impedance readings are “qualitative”; they “shall be correlated” with the moisture content of test samples extracted before producing the moisture profile section analysis.

The standard states pin moisture meters are relative, and the readings obtained should be recorded and correlated to the gravimetric analysis.

Did you know?

Appendix 2 in The NRCA Roofing Manual: Architectural Metal Flashing and Condensation and Air Leakage Control—2022 contains information regarding moisture readings, which require gravimetric analysis. The manual is available at shop.nrca.net.

Handheld pin moisture meters

There is no standard for using pin moisture meters on roofing materials. ASTM D7438 was designed for industrial use in the wood industry but also is used for roof moisture investigations by some individuals who may not understand their limitations. This leads to misdiagnoses in roof moisture meter readings.

ASTM D7438 states there are a number of issues affecting the accuracy of handheld meter readings, including use and interpretation of meters for conditions that relate to wood product characteristics, such as nonuniform grain, growth ring orientation and end-use process conditions. The standard also states calibration can be “impractical” or ”invalid.” Because it is not a standard for pin moisture meters used for roofing materials, there is not a way to calibrate them for different roofing materials.

In the wood industry, gravimetric analysis (a method to determine the amount of a substance by measuring its mass) is used to calibrate the moisture meter. ASTM D7438 also discusses the need to be aware of temperature correction and moisture gradients, as well as drift. If you follow this standard using a handheld pin moisture meter, take the time to become familiar with all terms and instructions in the standard.

There often are three scales used for measuring moisture: gypsum, paper and relative scale from 0-100%. Care must be taken to use the proper scales. The new fiberglass facers are not the same as paper facers and are not calibrated. Note that different adhesives can affect the pin moisture meter reading and be interpreted improperly.

From numerous cores tests when I have used pin moisture meters and gravimetric analysis, I have found pin moisture meters are fairly close to the paper facers using the Douglas Fir scale and gypsum scale for Georgia-Pacific DensDeck® cover boards with gravimetric analysis. The meter readings do not accurately follow the gravimetrics in roof insulation like EPS and polyisocyanurate. Pin moisture meters only sample extremely tiny areas between the pins. This is called the “electrode sensing region,” and many things affect the meter, including the temperature of the material and the moisture gradient of the material being tested.

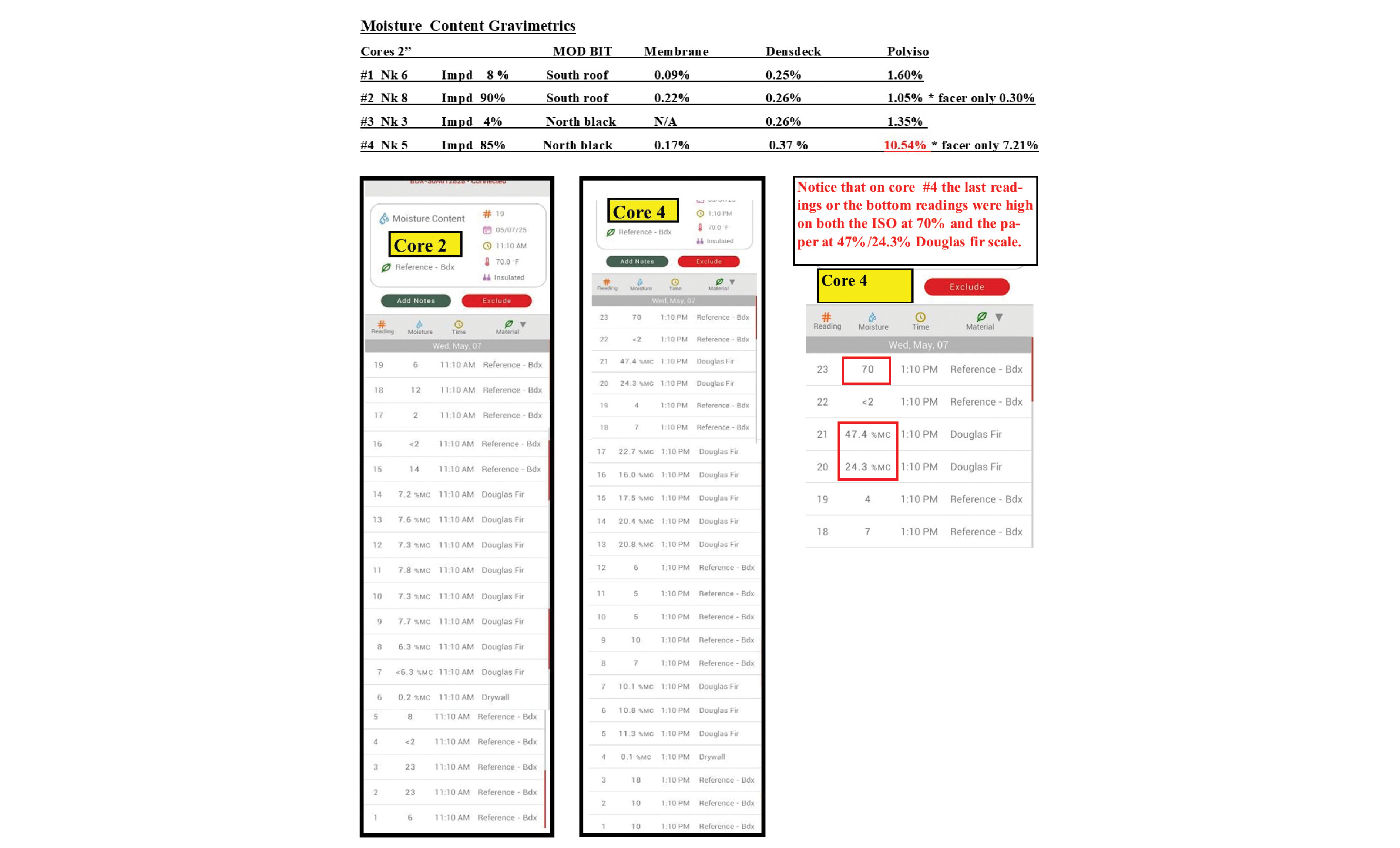

In Figure 2, my team took cores, nuclear gauge readings, Tramex impedance and pin moisture meter readings on a roof in Portland, Ore., this year. We took about 20 readings with the pin moisture meter as we removed the core for a quick reference to correlate with the gravimetrics. We started at the top and worked to the bottom of the core with the back of the membrane, both sides of a fiberglass-faced DensDeck cover board on reference scale, another layer of DensDeck (gypsum), two layers of paper-faced polyisocyanurate insulation on the Douglass Fir scale and finally polyisocyanurate insulation (reference) of at least two or three readings.

It is interesting to note on core 2 that both the nuclear gauge reading of 8 and the impedance of 90% did not match the gravimetrics, but the pin moisture meter did. On core 4, the impedance and the pin moisture meter aligned. We found the moisture was at the bottom of the deck as shown by the pin moisture meter readings of 47.4% paper facer and 70% polyisocyanurate.

Cover boards and insulation can have unevenly distributed moisture. For example, if there is a membrane breach and moisture is coming from the top of the polyisocyanurate or EPS insulation, the insulated pin meter will show a wetter area near the top. If moisture is coming from the bottom of the deck, the lower section of the core will be wetter. I recommend checking both facers and the top, bottom and center of the polyisocyanurate insulation. The accuracy of the readings depends on how representative the samples are of the entire core.

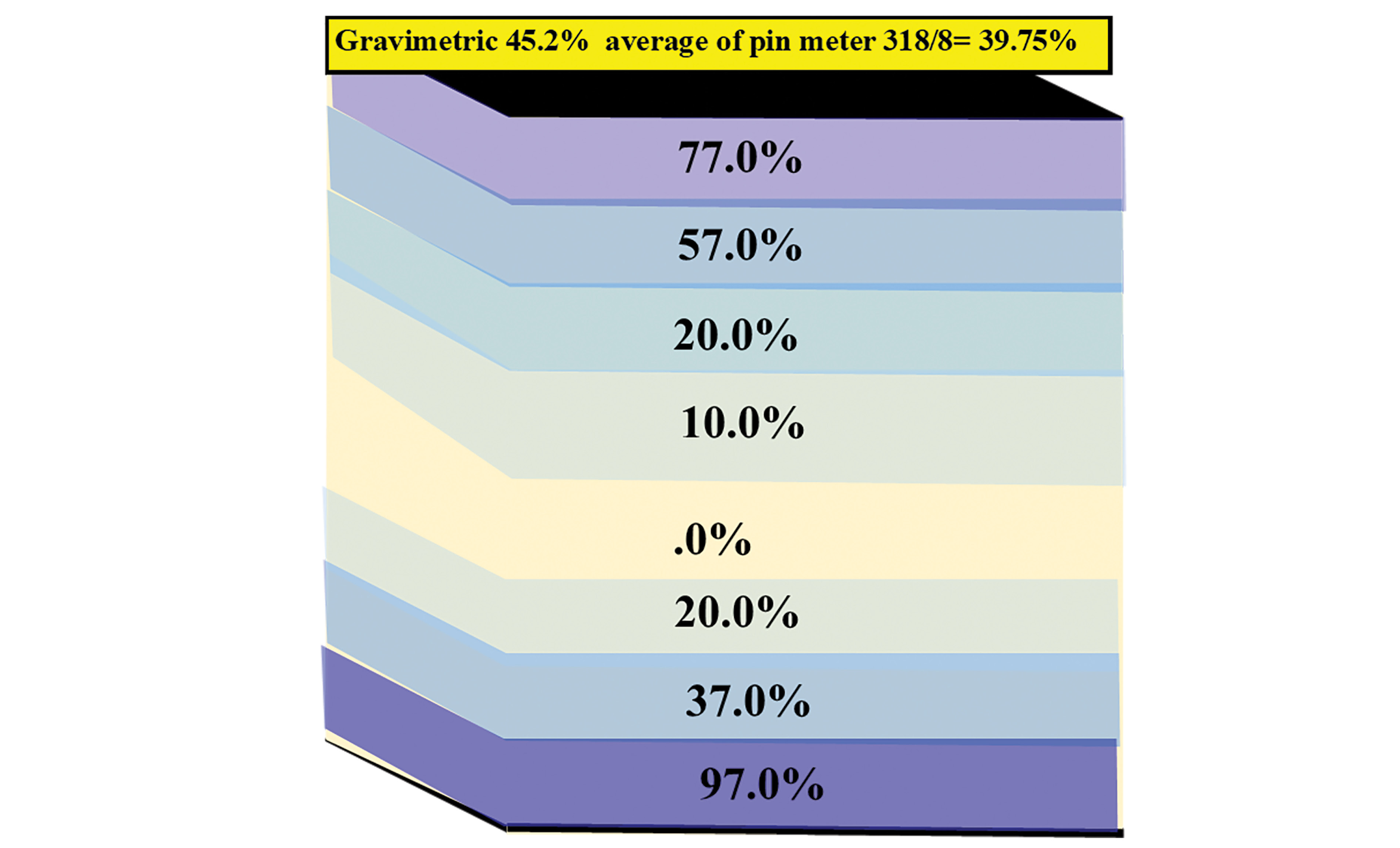

Figure 3 illustrates eight readings on a piece of polyisocyanurate insulation. When our team conducted a gravimetric analysis, it was closer to the total readings averaged. If we had taken a reading only in one location, it would not have been representative of the core as a whole. By taking multiple readings, we get a closer representation of the overall moisture content. If the readings are within close range to each other, it’s apparent the moisture distribution is fairly uniform.

Follow the standards

There are times when it is quite obvious roofing materials are wet or saturated. Yet there also are times when the moisture is only elevated. The question is whether it is normal ambient moisture or in the equilibrium moisture content range.

Infrared thermography, nuclear gauges and impedance gauges can find locations of possible moisture. These locations need verification as they are only relative or qualitative moisture measurement techniques.

Following the standards closely will help prevent errors when conducting moisture assessments.

MICHAEL T. WILLIAMS

Owner

White Glove Building Maintenance