An important consideration in roof system design is the environment in which a roof system will be exposed, but often little more than foot traffic and the weather are factored into the designs. Roofs must be able to withstand not only meteorological phenomena but also all the other things to which roofs are exposed. The purpose a building serves, the purposes nearby buildings serve and the location of equipment for other trades all play a role in a roof system's ability to perform well.

A roof membrane, whether it is built-up, polymer-modified bitumen or single-ply, can prematurely age when there is not chemical compatibility with its surroundings. Sources of chemicals that may be incompatible with roof membranes can be found in all sorts of places from exhausts to cleaning supplies to other roofing materials.

Sources of incompatible substances

Roof membrane chemical incompatibility is not binary. Instead, there is a spectrum a chemical falls on based on the effect it has on the membrane to which it is exposed. More mild interactions may result in nothing more than a reduction in a membrane's ability to resist ultraviolet (UV) exposure and heat, while in more severe cases contact between a chemical and a membrane could mean disintegration.

Chemicals listed by manufacturers as incompatible usually mean serious damage and premature roof failure can result, so these lists should be taken seriously. It is always a good idea to check with manufacturers about whether a chemical needs to be completely avoided or if exposure to it should be limited. Following are some sources of incompatible substances.

Rooftop exhaust

Depending on a building's usage, a roof system can adversely be affected by what comes out of a structure's chimneys and exhaust vents.

Animal and vegetable fats commonly end up in the exhausts of buildings where food is prepared, such as restaurants, banquet halls, hotels and grocery stores. Chlorine found in indoor pools and by-product chemicals from factories and manufacturing plants all can seriously compromise a roof system.

The roof system designer bears responsibility for ensuring a building's main function is explored and known so potential sources for incompatible substances can be discovered and minimized.

The atmosphere

The building on which a roof system is being designed or exists is not the only source of potential hazards to membrane compatibility. Nearby surroundings also must be considered.

GAF, Parsippany, N.J., provides a fairly comprehensive suggestion guide for membrane incompatibility, which states exposure to oils, diesels and jet fuels potentially can lead to rapid absorption and further degradation of thermoplastic membranes. Proximity to airports and areas where heavy machinery and factory equipment frequently is in use can be extremely important considerations when designing and/or maintaining a roof system.

Prior roof systems

A number of thermoset and thermoplastic membrane manufacturers, as well as some asphalt manufacturers, note in product literature their products are not compatible with petroleum-based products such as bituminous materials and should not be laid directly over such roof systems. In these cases, separation by a slip sheet or cover board is commonly recommended by manufacturers, as well as NRCA.

Other trades

Another major influence on roof membrane performance is rooftop work performed by other trades. HVAC units often end up on roofs and, as a result, so do the people who maintain the equipment. Evaporator coils require cleaning to function properly. However, a cleaner's chemical composition can drastically vary and, in some cases, lead to incompatibility issues with the membrane. Some cleaners basically are just a detergent, which is resisted well by most membranes, while others can contain strong oxidizing agents such as strong acids or strong bases—both can be bad news for most membranes. This problem is compounded when those responsible for an HVAC unit have no knowledge of the roof system the unit sits on or what chemicals can cause compatibility problems.

When work must be completed on a roof, knowledge about the roof system's materials is important even in situations when the roof system itself is not what requires attention.

Single-ply membranes

Within the single-ply membrane realm, different materials and manufacturers exist, resulting in differences in levels of chemical resistance and suggested tolerances for exposure to certain materials.

While conducting research for this article, I reviewed information provided by Canadian General Tower Ltd., Cambridge, Ontario; Carlisle Construction Materials, Carlisle, Pa.; Cooley Engineered Membranes, Pawtucket, R.I.; Duro-Last® Inc., Saginaw, Mich.; Fiber-Tite, Wooster, Ohio; Firestone Building Products Co. LLC, Nashville, Tenn.; Flex Membrane International Corp., Leesport, Pa.; GAF; IB Roof Systems, Irving, Texas; Johns Manville, Denver; Mule-Hide Products Co. Inc., Beloit, Wis.; Sika® Sarnafil, Canton, Mass.; and Tremco Inc., Beachwood, Ohio.

Although all these organizations were considered, only about half had readily available product information regarding chemical compatibility of the membranes they produced, and fewer still had more than a couple of sentences within application instructions.

EPDM

EPDM membranes have some vulnerability when exposed to animal fats and oils from vegetables and animals, as well as petroleum-based products such as gasoline and other fuels. Johns Manville makes special mention to avoid direct contact with other roofing products such as bituminous systems, which also may lead to incompatibility issues.

TPO

Among thermoplastic polyolefin (TPO) membrane manufacturers, there are fewer reservations about exposure to fats and oils, but Mule-Hide Products stresses caution be taken to avoid situations where direct contact with mineral oils, vegetable oils, animal oils and animal fats could occur.

GAF provides comprehensive recommendations for its TPO products and allows for use in areas where fats and grease are present though it notes some reduction in UV and heat resistance may result. Furthermore, and more fairly representative of the market, it suggests avoiding strong oxidizing agents, strong and dilute acids, oils, diesels, jet fuels and solvents.

PVC

According to manufacturer information, PVC exhibits similar strengths and weaknesses in chemical compatibility as TPO. Some manufacturers note an increased susceptibility to some acids and fats. Grease, diesels, fuel (including jet fuels), solvents and oils should be avoided.

Duro-Last provides a list of other roofing materials that create incompatible substrates. It suggests using a slip sheet or cover board between new membranes and other items listed, including acrylic coatings; extruded polystyrene; polymer-modified bitumen; shingles; aluminum-coated asphalt; granulated cap sheets; "old" Duro-Last roofs; TPO membranes; coated or smooth asphalt; polyurethane; sprayed urethane foam; expanded polystyrene; mineral-surfaced caps; coal-tar pitch; and PVC/CPA membranes.

Other single-ply membranes

Although a vast majority of single-ply membranes in the current market fall into one of the previously mentioned categories, a few manufacturers make other products. Most of these are classified as either ketone ethylene ester (KEE) or a KEE-PVC blend.

Also included is Carlisle Construction Materials' polyepichlorohydrin membrane and Tremco's TPA. These do not appear to perform dissimilarly to other thermoplastic membranes. GAF literature suggests its self-produced KEE-PVC blend undergoes less absorption and degradation when exposed to fats, oils, fuels, diesels and diluted acids than their other thermoplastic membranes.

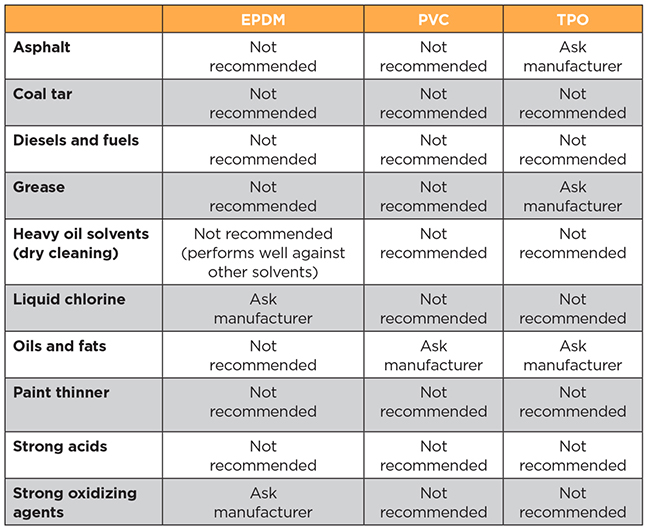

Figure 1: Chemical compatibility of single-ply membranes |

Figure 1 shows 10 common roofing environment materials and how the three most prominent single-ply membranes in the market perform against them. The resistance descriptions are not standard for all EPDM, PVC and TPO membranes manufactured but are based on themes present across manufacturers of the same membrane type. Still, it's important to consult the manufacturer to be sure, on a case-by-case basis, how well a membrane will perform in a given situation.

Bituminous roof system

Concerning chemical compatibility, membranes made from bitumens such as asphalt, polymer-modified asphalt and coal tar are robust roofing materials. All are time-tested membranes with many similarities.

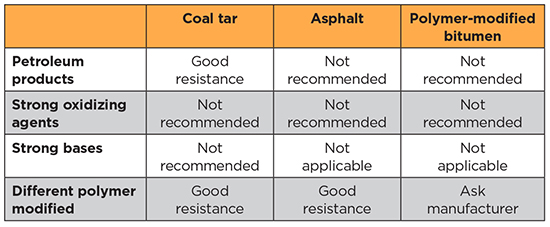

Roof systems made from asphalt, a product derived from petroleum, are more susceptible to interactions with other substances derived from petroleum such as oils, fats and fuels. Coal tar does not have the same compatibility issues with other substances derived from coal or petroleum products.

Figure 2: Chemical compatibility of bituminous membranes |

Among asphalt-based polymer-modified bitumen roof membranes and products, manufacturers suggest materials in each roof system stay consistent regarding the type of polymer used. Although no mention is made about APP and SBS polymer-modified membranes being incompatible, the manufacturers recommend they not be used together. Figure 2 reflects the chemical compatibility of these types of roof membranes.

Manufacturer literature

Across the industry, different membrane manufacturers have different ideas about how much information to disclose and how to make the information available to the public.

For some manufacturers, chemical compatibility is a marketing opportunity and the companies share information about the chemicals and substances their membranes resist. Other companies outline the compatibility of their products but do not disclose the information to the public, instead offering help on a case-by-case and chemical-by-chemical basis. This means for every new brand of cleaning chemicals introduced, a call should be made to the roof membrane manufacturer to clarify chemical compatibility.

Other companies suggest consumers partake in their own studies and trials to see how membranes will react in their individual situations. Although there are a few manufacturers that do a good job providing information about the materials they produce, there are some independent parties such as the Canadian Roofing Contractors Association that provide general information about compatibility.

It is easy to see there is room for improvement for the consumers' sake. Certainly, the last thing a manufacturer wants is a consumer injured while conducting at-home tests. Research and literature development is a small price to pay comparatively.

Organizations such as SPRI, the EPDM Roofing Association and the Asphalt Roofing Manufacturers Association also could help provide or recommend information.

Help to educate

When considering membranes and roof systems, you need to be aware of the chemicals to which each unique roof may be exposed. To ensure roof systems are properly maintained and help avoid trouble resulting from other trades' roofing work, you should help educate building owners about what their roof systems can and cannot handle chemically.

On the manufacturer side, customers need full access to information about product chemical compatibility, and manufacturing companies need to conduct additional research and make the information more readily available to the public. Successful roof systems start with educated consumers, and this demands the availability of information, literature and education from resources dedicated to membranes.

Kurt Fester is NRCA's project engineer.

For an article related to this topic, see "Roof coating forensics," December 2013 issue.