|

Thermal resistance, commonly referred to as R-value, is a measure used to report the thermal performances of building materials, products, systems and assemblies. In the roofing industry, R-value also is used as a basis for comparing insulation products. It is important you understand how R-value is derived and tested, as well as guidelines and regulations for reporting and product labeling R-values.

R-value

ASTM C168, “Standard Terminology Relating to Thermal Insulation,” defines R-value as “the quantity determined by the temperature difference, at steady state, between two defined surfaces of a material or construction that induces a unit heat flow rate through a unit area.” In English (inch-pound) units, R-value is expressed as h•tf2•F/Btu.

The R-value of homogenous materials and products typically is tested using ASTM C518, “Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus.” The testing’s outcome is a thermal conductance value, commonly referred to as C-factor, expressed in inch-pound units as Btu/h•tf2•F.

The R-value of systems or assemblies commonly is tested using ASTM C1363, “Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus.” This testing’s outcome is a thermal transmittance value, commonly referred to as U-factor, and also is expressed in inch-pound units as Btu h•tf2•F.

C-factor and U-factor are the mathematical inverse of R-value (R = 1/C, R = 1/U).

The concept of using R-value rather than C-factor and U-factor for reporting thermal performances originated with a Penn State University researcher, Everett Shuman, in the mid-1940s. Shuman contended the R-value concept was easier for users to comprehend and use. Higher R-values represent higher levels of thermal performance. Also, R-values for multiple materials or products can be readily mathematically added; C-values cannot.

By the mid-1970s, the R-value concept had become more common. Now, it is widely recognized as the basis for reporting thermal performances of building materials, products, systems and assemblies.

R-value rule

The Federal Trade Commission first established an R-value rule in 1979 in response to several unfair and deceptive insulation cost-savings claims and to standardize reporting residential insulation products’ R-values.

The current R-value rule is identified as 16 CFR Part 460, “Labeling and Advertising of Home Insulation: Trade Regulations.” It is intended to apply to home insulation manufacturers, professional installers and retailers who sell insulation for do-it-yourself installation and new home sellers. It also applies to laboratories that conduct R-value tests for these entities.

The R-value rule identifies specific testing methods and procedures. For example, testing of mass insulation products is required to be conducted at a mean temperature of 75 F. Tests for polyurethane, polyisocyanurate and extruded polystyrene insulation must fully reflect the effect of aging. Tests for loose-fill insulation products must account for settling on the products’ R-values.

The R-value rule also requires applicable entities to disclose R-value and other relevant information, such as thickness and coverage area per package, on product labels and manufacturers’ product literature.

The FTC has indicated the R-value rule specifically does not apply to insulation sold for use in commercial, industrial, institutional and retail buildings.

Code requirements

The International Energy Conservation Code® requires insulation R-values to be determined in accordance with the FTC’s R-value rule.

The requirement applies to residential buildings covered by IECC’s residential provisions and nonresidential buildings, including commercial, industrial and retail buildings, covered by IECC’s commercial provisions. IECC also includes additional requirements specific to product labeling.

The International Code Council®'s inclusion of the FTC R-value rule in IECC’s commercial provisions conflicts with and is outside of the FTC’s intended applicability of the R-value rule.

Closing thoughts

The FTC’s R-value rule provides a regulatory-backed basis so consumers can rely upon manufacturers’ R-values for residential insulation products.

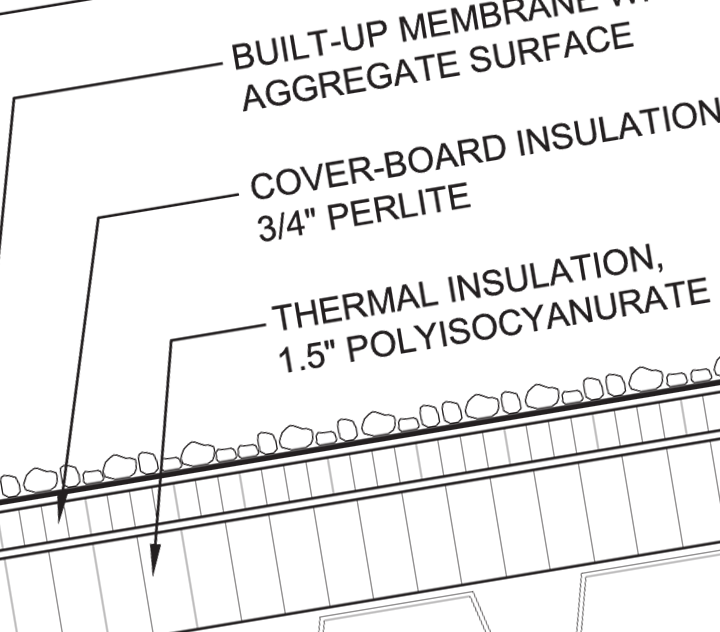

ASTM International product standards for most insulation products include minimum R-values derived in compliance with the FTC’s R-value requirement. ASTM C578, “Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation,” which applies to expanded and extruded polystyrene, contains R-values based on 25 F, 40 F and 110 F mean temperatures. ASTM C1289, “Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board,” which applies to faced-polyisocyanurate insulation, contains R-values based on 40 F and 110 F mean temperatures. Designers can use R-values based on mean temperatures other than 75 F for specific design purposes provided R-values based on 75 F are used for code compliance. Designers may want to use R-values other than those based on a 75 F mean temperature when determining vapor retarder placement, for cold storage buildings or in cold or hot climates, for example.

NRCA recommends insulation be specified by designers and procured based on its ASTM designation and thickness, not by specifying its R-value.

Additional information about R-values, C-factors and U-factors and rigid board insulation products is provided in Chapter 4-Rigid Board Insulation of The NRCA Roofing Manual: Membrane Roof Systems.

MARK S. GRAHAM is NRCA’s vice president of technical services.

This column is part of Research + Tech. Click here to read additional stories from this section.