Attic ventilation can be a confusing, complex subject and is the topic of many discussions, research papers and articles. For example, in the June 2012 issue, the article "Vexing ventilation issues" focuses on building code requirements for attic ventilation. In the article, there was some discussion about unvented attic assemblies because the 2009 International Residential Code® (IRC) introduced provisions allowing this construction type. Some readers found the concept of unvented attics even more confusing than attic ventilation. And NRCA has received numerous calls from homeowners and contractors regarding converting existing attics into unvented attics.

Basic concepts

Ventilating attic spaces is viewed by many roofing professionals as a technical requirement for steep-slope roof assemblies and often is a building code requirement. However, as mentioned, attics can be designed to be vented or unvented.

Vented attics

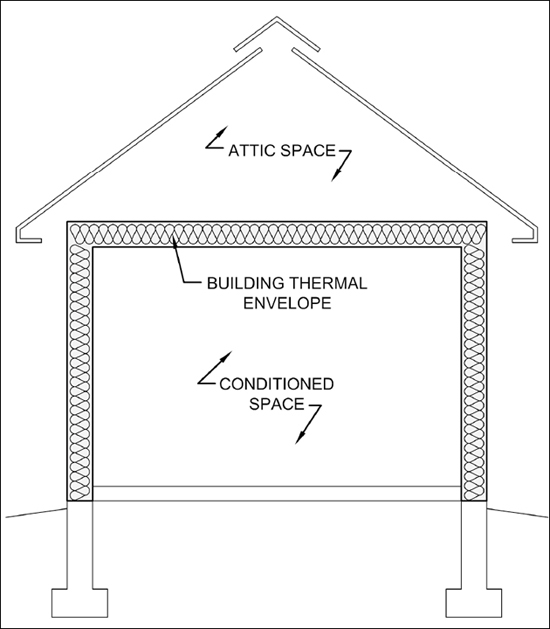

A vented attic space has intake vents that allow outside air to enter an attic space and outtake vents that allow air to exit. In these cases, insulation typically is installed on top of the attic floor and a vapor retarder is installed in the ceiling and attic plane; therefore, a building's thermal envelope encompasses the exterior walls, attic and ceiling assembly (see Figure 1).

Figure 1: Diagram of a vented attic space

A vapor retarder controls how quickly water vapor transfers through building envelope materials. Ceiling vapor retarders are used in cold climate locations that experience outward vapor drive during most of the year.

It is important to note vapor retarders by definition are not intended to control water vapor transported by air leaks. Additional design features and detailing steps during installation may be included to control air leaks. When configured and installed in this fashion, a vapor retarder also functions as an air retarder (see "Air barrier or air retarder?"). A ceiling air retarder minimizes air flow between conditioned and unconditioned attic spaces. A ceiling air retarder's primary purpose is to minimize air transport between conditioned and unconditioned spaces.

Uncontrolled flow of conditioned air into unconditioned attic or rafter spaces is a concern during cold weather because water vapor contained in conditioned air condenses when it contacts cold surfaces. If air leaks aren't prevented or the moisture-laden air isn't ventilated outside, condensation may damage a roof assembly's moisture-sensitive components.

Unvented attics

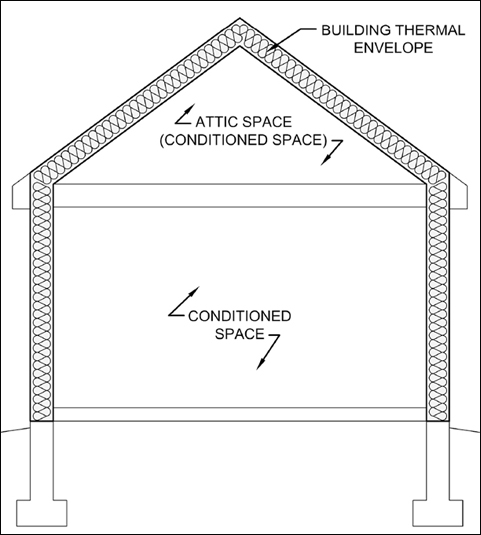

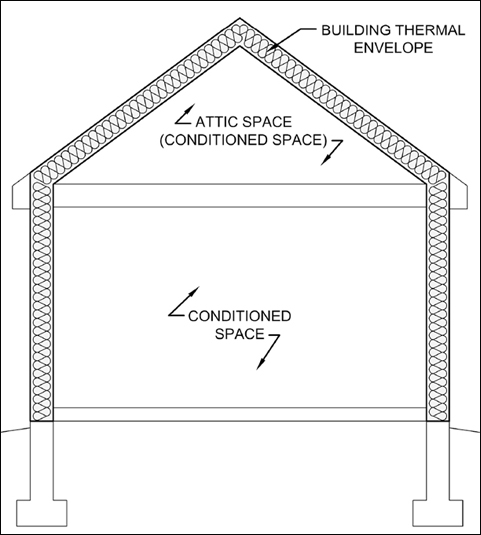

Figure 2: Diagram of an unvented attic space

An unvented attic space consists of the insulation and air retarder located at roof level instead of ceiling level. The attic space is considered a conditioned space because it is located within a building's thermal envelope. In this case, insulation typically is located below the roof deck inside rafter spaces (see Figure 2).

Design considerations

Vented or unvented attics can exist anywhere in the U.S. The decision to vent an attic space is not dictated by building code; it is a design choice.

When choosing between a vented and unvented attic, there are some design considerations for new construction, which follow.

Vapor retarder installation

Vented attic assemblies work best if you can control moisture entry and accumulation. It is critical the interface between the walls, ceiling and all penetrations, such as recessed light fixtures or pipes/conduits, be properly sealed.

Also, it becomes difficult to achieve proper vapor retarder installation if there are multiple dormers, tray (coffered) ceilings or interior (drop) soffits. In other words, it might be difficult to have an effective vapor retarder (or air retarder) installation with a building that has a complex ceiling design and/or numerous penetrations.

In unvented attics, the air retarder is located at roof level, so having a complex ceiling design and/or multiple penetrations would not be an issue.

Mechanical equipment

HVAC units and ductwork located in a vented attic space could lead to problems. If air leaks from ductwork, it may lead to condensation occurring on equipment and ductwork in hot, humid climates and ice dams in cold climates. And in all climate zones, there is the potential for increased energy costs.

An unvented attic space takes advantage of the "whole house" approach to thermal and moisture control by taking into consideration a building's mechanical system. Unvented attics eliminate extreme temperatures in the attic, so it is beneficial to have HVAC units and ductwork in an attic space that is conditioned. The primary benefit is the mechanical system is not delivering cooled air through a hot summer attic and heated air through a cold winter attic.

Also, the effect of ductwork air leakage is negated when mechanical systems are placed in a conditioned attic. Such air leakage typically accounts for 10 to 20 percent of air handler flow. The reduction of the effect of ductwork leakage typically more than offsets the increased volume of conditioned air created by moving the air and thermal barrier from the ceiling to the roof plane.

High-wind regions

Along coasts (especially in hurricane-prone regions), vented attic assemblies are prone to wind-driven rain entering soffit vents or damage caused by building pressurization issues. Obviously, soffit vents aren't used with unvented attics, so these issues aren't a concern in such cases.

Increased roof temperatures

Some roofing professionals criticize the unvented, conditioned attic concept. They contend the increased roof surface temperatures that result from nonvented deck substrates will cause premature roof system deterioration, particularly with bitumen-based roofing products.

Although roof surface temperatures will be warmer over unvented, conditioned attics, these temperature increases are less than or equal to the amounts attributable to other readily identifiable sources, including building location and orientation and roof surface color.

Code issues

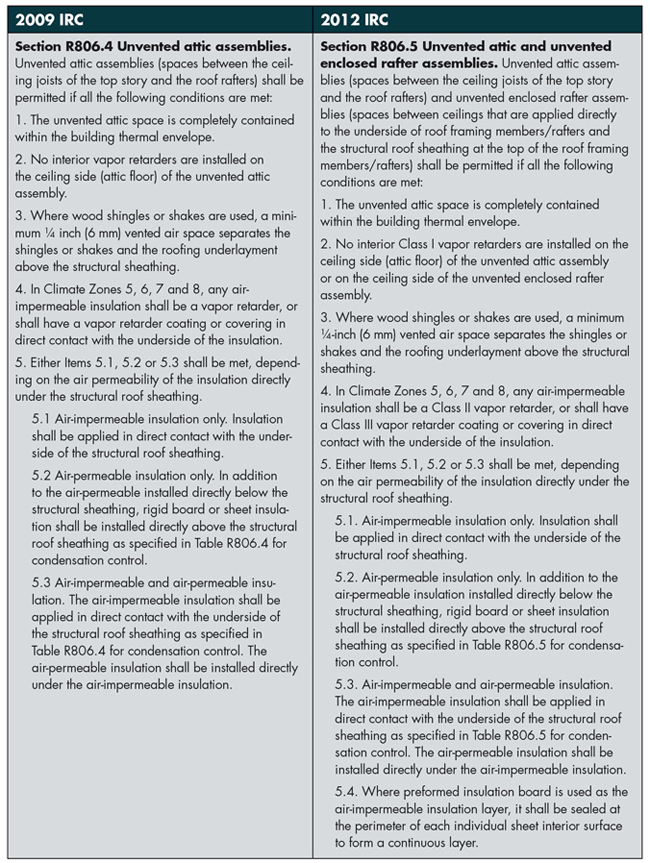

Requirements for unvented attics can be found in IRC's Chapter 8—Roof-Ceiling Construction. Figure 3 illustrates a side-by-side comparison of the requirements excerpted from the 2009 and 2012 editions of IRC. Note both editions essentially require the same five conditions be met to have an unvented attic.

Figure 3: Comparison of 2009 and 2012 editions of the International Residential Code® (IRC)

The first condition is an attic space should be completely contained in the building envelope. This means the insulation and air retarder (essentially the building envelope) are located at roof level instead of ceiling level. The building code considers the roof as the main barrier for keeping water from entering the attic.

Second, you should not have a vapor retarder at ceiling level. This applies in all climate zones. In traditional vented attic assemblies, a vapor retarder would be installed on the attic floor. The reason for this requirement is you don't want to separate the conditioned attic space from the building's other conditioned spaces. According to IRC code commentary, this requirement gives the attic space a limited potential to dry into the space beneath the attic so small amounts of excess moisture can be removed from the attic.

The third condition specifically is for buildings with wood shakes and wood shingles in all climate zones. These roof coverings require a vented space to allow for drying conditions.

The fourth condition applies to U.S. climate zones 5, 6, 7 and 8. If air-impermeable insulation is used, it should be a Class II vapor retarder or have a Class III vapor retarder coating or covering installed on its underside.

The building code defines three classes of vapor retarders based on a material's or assembly's ability to limit the amount of moisture that passes through it. The International Building Code® (IBC) prescribes the use of ASTM E96, "Standard Test Methods for Water Vapor Transmission of Materials," to determine class type, which follow:

- Class I: 0.1 perm or less

- Class II: 0.1 < perm = 1.0 perm

- Class III: 1.0 < perm = 10.0 perm

The final condition dictates where insulation should be located and depends on the air permeability of the insulation installed directly under the structural roof sheathing. This item requires sufficient insulation to keep moisture from condensing inside the attic under average conditions. The condensing surface is the interior of the roof deck for air-permeable insulation and interior of the insulation for air-impermeable insulation.

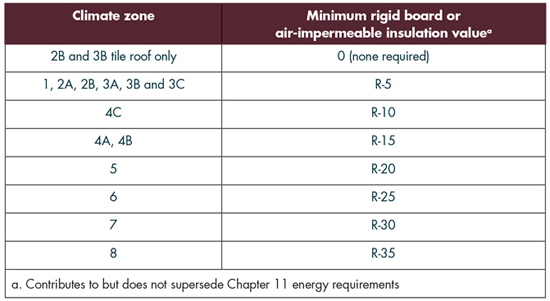

To prevent condensation, the condensing surface's temperature must be warmer than the dew point temperature. To ensure this, adequate amounts of insulation are needed. Table 806.4 (IRC 2009) and Table 806.5 (IRC 2012) provide for minimum R-values for air-impermeable insulation (see Figure 4).

Figure 4: IRC Table R806.5

According to IRC commentary, condensing surfaces differ because attic air can be circulated through air-permeable insulation to contact the roof deck but can only get to the interior of air-impermeable insulation. The air-impermeable insulation requirement ensures air and moisture will not pass through the insulation. Also important to note, the insulation R-values found in Tables 806.4 and 806.5 may be more or less than what is required for energy efficiency found in IRC's Chapter 11. These requirements contribute to but do not supersede the thermal requirements in Chapter 11.

As a side note, there will be another option in the insulation location requirement in IRC's 2015 edition. The alternative will permit all insulation to be installed above structural roof sheathing. The amount of rigid board or sheet insulation must be sufficient enough to maintain the monthly average temperature of the structural roof sheathing's underside above 45 F. For calculation purposes, an interior air temperature of 68 F is assumed and the exterior air temperature is assumed to be the monthly average outside air temperature of the three coldest months. Keep in mind, steep-slope roof coverings require a nailable substrate for proper installation. Therefore, a roof assembly will need to include a layer of nailable substrate, such as plywood, over the rigid board or sheet insulation.

Additionally, other IRC sections have requirements applicable to unvented attics that cannot be modified or eliminated. Some applicable sections are R302.10—Flame spread index and smoke-developed index for insulation; R302.13—Combustible insulation clearance; R316—Foam Plastic; R807—Attic Access; and N1102—Building Thermal Envelope.

One example is if foam plastic insulation (such as spray polyurethane foam [SPF]) is used. The requirements of IRC's Section R316 must be applied, and a thermal barrier or protection from ignition is required. Per Section R316.4—Thermal Barriers, all foam plastic insulation must be separated from a building's interior by an approved 15-minute thermal barrier. An example of a commonly used thermal barrier is 1/2-inch-thick gypsum wall board.

There is an option not to use a thermal barrier; however, the foam plastic insulation must be protected by an ignition barrier material, such as 1 1/2-inch-thick mineral fiber insulation or 1/4-inch-thick wood structural panels.

Retrofitting an existing attic

With the desire for lower energy bills, some homeowners are thinking about converting existing attics to unvented attics.

As with any project, the renovation work should comply with the applicable building code, including the conditions for unvented attics listed under Sections 806.4 (IRC 2009) and 806.5 (IRC 2012).

For example, one condition is a vapor retarder cannot be installed in the ceiling or attic plane; if one exists, it should be removed. Also, it typically is advised existing attic floor insulation be removed, as well, because the concept is to have the unvented attic space contained in a single thermal building envelope.

Different types of insulation can be used, but the most popular is SPF. SPF conforms to any shape, bonds to all surfaces and seals around penetrations; has one of the higher R-values per inch thickness compared with other insulations; can provide air and vapor control in addition to thermal control (depending on SPF type and installed thickness); and, depending on the SPF type, provides some degree of water resistance.

There are two broad SPF categories: open cell and closed cell. Also, SPF is further defined by density. There are three major density categories:

- Light: 0.5 pounds per cubic foot

- Medium: 2 pounds per cubic foot

- High: 3 pounds and greater per cubic foot

Open-cell and closed-cell SPF can be used in unvented attic projects. The most commonly used are light-density open-cell SPF and medium-density closed-cell SPF. Deciding on which type to use on a project depends on the design requirements and what physical properties are desired. Figure 5 provides a side-by-side comparison.

Figure 5: Open-cell vs. closed-cell SPF

Closed-cell SPF is denser than open-cell SPF. Open-cell SPF typically can be installed to a desired thickness in one pass. Closed-cell SPF requires multiple passes to achieve a desired thickness. Consequently, more material is needed with closed-cell SPF, making it more expensive than open-cell SPF.

But there are some benefits to closed-cell SPF that could make it worth the extra cost. For instance, closed-cell SPF has a high-tensile strength and can provide extra structural benefit for wind-uplift resistance of a building's structural system. This would be advantageous for buildings located in high-wind regions. Also, closed-cell SPF resists water absorption and may serve as a secondary layer of weatherproofing.

And as previously mentioned, SPF insulation is a foam plastic insulation; therefore, a thermal barrier or protection by an ignition barrier is required.

Lastly, an unvented attic assembly helps reduce air leakage and energy loss, but it can change the dynamics of a building's ventilation system. Improving a building's air tightness will affect the ventilation of combustion appliances (such as gas-powered hot water heaters or dryers) and affect indoor air quality. And in a worst-case scenario, it could result in higher levels of carbon monoxide, creating a hazardous situation for building occupants.

Therefore, it is in a homeowner's best interest to have the finished work evaluated by a trained energy professional who measures air leakage and carbon monoxide levels. Building Performance Institute Inc., Malta, N.Y., is an example of an organization that offers a certification program for energy professionals and company accreditation. Air leakage testing also will help determine what adjustments and/or modifications need to be made to the mechanical system. It also would be beneficial to perform testing before work begins to provide baseline information.

There is a standard applicable to single-family homes to determine acceptable indoor air quality, and it takes into account the chemical, physical and biological contaminants that can affect air quality. ASHRAE 62.2-2010, "Ventilation and Acceptable Indoor Air Quality in Low-rise Residential Buildings," prescribes minimum requirements for mechanical and natural ventilation systems intended to provide acceptable indoor air quality.

Three primary sets of requirements are set forth in the standard: whole house ventilation, local exhaust and source control. Whole house ventilation is intended to address unavoidable contaminant emissions from people and materials. Local exhaust is intended to remove contaminants from specific rooms such as bathrooms and kitchens. And source control addresses issues such as combustion and solid-fuel burning appliances, clothes dryers, size of ventilation openings and airtightness requirements.

In closing

There are many important factors to consider when deciding whether to change an existing attic into an unvented attic. It should not be regarded as an easy renovation project where you are simply spraying SPF in an attic space. If done improperly, it could lead to unsafe consequences.

NRCA maintains its longstanding recommendation to properly ventilate attic spaces. However, NRCA considers unvented attic assemblies to be a viable alternative to attic ventilation throughout the U.S. Vented and unvented attics can be successful if properly designed and constructed.

Joan P. Crowe, AIA, AIA, is an NRCA director of technical services.

For articles related to this topic, see:

- "What's the value of ventilation?" March 2002 issue, page 20

- "Vexing ventilation issues," June 2012 issue, page 32

Air barrier or air retarder?

The term "air barrier" often is used when referring to preventing or controlling air leakage through a building's envelope. Many test standards and some codes use this term and then go on to describe prescriptive methods for controlling air leakage or air-leakage rates that do not provide for zero air leakage—that being an absolute barrier.

In reality, it virtually is impossible to create an absolute barrier from all vapor leakage, air leakage, and moisture and air permeance. For this reason, NRCA considers the term air barrier to be a misnomer. NRCA has adopted the term "air retarder" for what some refer to as air barrier.