Editor's note: The following article is part two of a two-part series. Part one was published in the February issue and provided background information about the topic.

Part one of this series provided details about the new Occupational Safety and Health Administration's (OSHA's) respirable crystalline silica (RCS) regulation's provisions, and the nature of the health hazards related to workplace silica exposure were discussed.

Following are specifics in the rule allowing for the use of objective data to assess worker exposure to RCS and some of NRCA's preliminary findings from initial air-monitoring sampling. The rule allows for use of objective data to exempt a contractor from air-monitoring requirements and provide a basis for respirator selection if necessary. OSHA notes reliance on objective data is intended to provide the same degree of assurance air monitoring of worker exposures through personal breathing samples does, so there is a specific record-keeping requirement. The rule requires objective data to reflect workplace conditions closely resembling the processes, material types, control methods, work practices and environmental conditions as in the contractor's current operations. Industry data are acceptable under the rule's definition of the term.

NRCA action

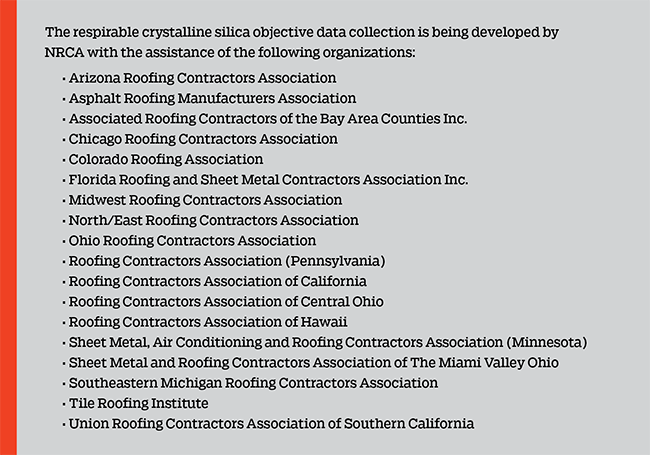

In summer 2017, with support of a number of its affiliate organizations, NRCA started collecting personal breathing zone and area samples from select roofing job sites with the assistance of a number of its contractor members. The goal established by NRCA's Silica Task Force was to catalog details of roofing tasks and processes that could form the basis for industry-wide objective data and possibly reduce the burden of the regulation on roofing contractors.

NRCA now has preliminary objective data that reflect a majority of roofing work does not involve levels of exposure to RCS that are dangerous to workers. The main roofing tasks the sampling focused on were the removal and installation of asphalt shingle, polymer-modified bitumen and built-up roof (BUR) systems. However, data are available for operations such as drilling into masonry, cutting of clay and concrete tiles and pavers, installing and removing gravel, installing gypsum roof boards and other roofing tasks.

A test method and sampling protocol were established with the assistance of the industrial hygiene companies that performed the sampling to ensure a uniform sampling procedure and sample collection and testing under methods established by OSHA.

Sampling results

To date, NRCA has completed personal breathing zone and area air sampling on four asphalt shingle removal projects and four asphalt shingle roof system installations.

The removal projects predominantly involved the use of hand tools to tear off the shingles and underlayment materials. Work areas ranged from about 1,000 to 5,000 square feet, and the precise age of the weathered material removed varied but was not specifically determined or specified in the reports. No worker exposure during any of the asphalt shingle removal projects exceeded the action level for RCS set by OSHA as an eight-hour time-weighted average.

Installation projects typically involved the use of pneumatic nail guns and manual cutting methods. Asphalt shingle products from various manufacturers were installed and included an underlayment. No worker exposure during any of the asphalt shingle installation projects exceeded the action level for RCS set by OSHA as an eight-hour time-weighted average. Additionally, exposures to total respirable particulate were below OSHA's general industry permissible exposure limit (PEL) for removals and installations.

NRCA has received reports of sampling performed on one polymer-modified bitumen roof system removal, two polymer-modified bitumen roof system installations, three BUR system removals and three BUR system installations. Other similar projects have been sampled, but final reports have not been received with analyzed worker exposure levels. Work areas ranged from about 1,000 to 4,000 square feet with manual methods of removal and the use of powered roof cutters on some projects. Debris removal on these projects ranged from manual sweeping and shoveling to the use of a motorized gravel sweeper and leaf blower. Installing polymer-modified bitumen involved the use of torches in both jobs sampled with CertainTeed Flintlastic® GTA cap sheet installed on one project and Siplast Paradiene® 20 PR TG installed on the other. No worker exposure during any of the reported polymer-modified bitumen or BUR projects exceeded the action level for RCS set by OSHA as an eight-hour time-weighted average. Additionally, exposures to total respirable particulate were below OSHA's general industry PEL for both removals and installations.

In related sampling, an 8,500-square-foot work area with a recently installed BUR system was flood-coated with hot asphalt and gravel was dispersed over the freshly applied asphalt. None of the six workers who were performing tasks related to the described work procedures had RCS levels near or above the action level, and total respirable particulate was at levels well below the PEL.

The objective data initiative NRCA has undertaken also has been considering other common roofing tasks, such as drilling into concrete or masonry for installing termination bars and other fastening hardware, fastening gypsum roof boards and ballast removal. Three sampling reports from projects that involved drilling a range of about 80 to 200 holes into concrete using electric drills that were not equipped with dust collection showed exposures below OSHA's action level for RCS as well as low levels of total respirable particulate.

Two sampling projects that involved fastening Georgia-Pacific DensDeck® gypsum roof board also showed RCS levels below the action level and low levels of total respirable particulate. One project was about 700 square feet, and the material was cut with razor knives, hand saws and a reciprocating saw. Debris was cleaned with a leaf blower. The other project involved about 6,500 square feet of material fastened into a metal deck.

Two workers removed roof ballast using shovels and a vacuum with a long suction tube that deposited materials into the bed of a dump truck positioned on the ground below the roof work area. The workers were exposed to RCS at a level below the action level set by OSHA and total respirable particulate at a level below OSHA's general industry PEL. However, two area samples collected indicated a level above the action level set by OSHA.

Record keeping

NRCA's objective data collection is accessible via the Members Only section of www.nrca.net; a document summarizes the projects and sampling results that have been reported. (Note: You will need your NRCA member ID to log in to view the results.)

NRCA is maintaining the original lab reports for each project in the event OSHA compliance officials request to review the details of the sampling. Workers' personal information and other identifiers of a sensitive nature have been removed.

If you develop and maintain objective data for your own projects, remember OSHA regulations require you to maintain a record of the source of the data; the silica-containing material; the test protocol and results; and a description and other details regarding the process, task or activity on which the data are based. OSHA views objective data similar to employee exposure records, so the rule requires the data be maintained for a period of at least 30 years.

Going forward

NRCA is maintaining the objective data collection as a living document so additional sampling results can be added to the collection as areas of potential exposure are discovered and supplemental results for sampled roofing tasks are reported. Additionally, member contractors have submitted sampling results for projects they have undertaken that may involve exposure to silica based on materials in place or the safety data sheets of materials being installed. If suitable, these projects will be added to the objective data collection.

|

Since initial publication of the proposed silica rule, NRCA has been actively encouraging OSHA to tailor the requirements of any rule with an eye toward the more significant hazards—specifically falls—that roofing workers face while performing tasks that may involve silica exposure. Preliminary sampling results for the objective data collection indicate a relatively reduced risk for most roofing workers when it comes to RCS.

Because of this, it is important fall hazards in roofing remain the key focus for worker safety. There are areas of exposure to RCS in roofing that may demand engineering controls under Table 1 of the regulation that could increase the likelihood of falls. NRCA wants to sustain the focus on working safely at heights to ensure roofing workers not only are protected from the health hazards related to silica but also kept secure from fall hazards that may be compounded by provisions of the RCS rule.

Harry Dietz is an NRCA director of enterprise risk management.