With global urbanization and the increasing density of the built environment, it has become difficult to escape sound completely. For this reason, an additional challenge to the design and construction of commercial buildings has arisen: the need to address noise transmission in high-performance enclosures.

From the acoustical point of view, noise and sound constitute the same phenomenon. However, noise generally is considered a disagreeable and undesired sound.

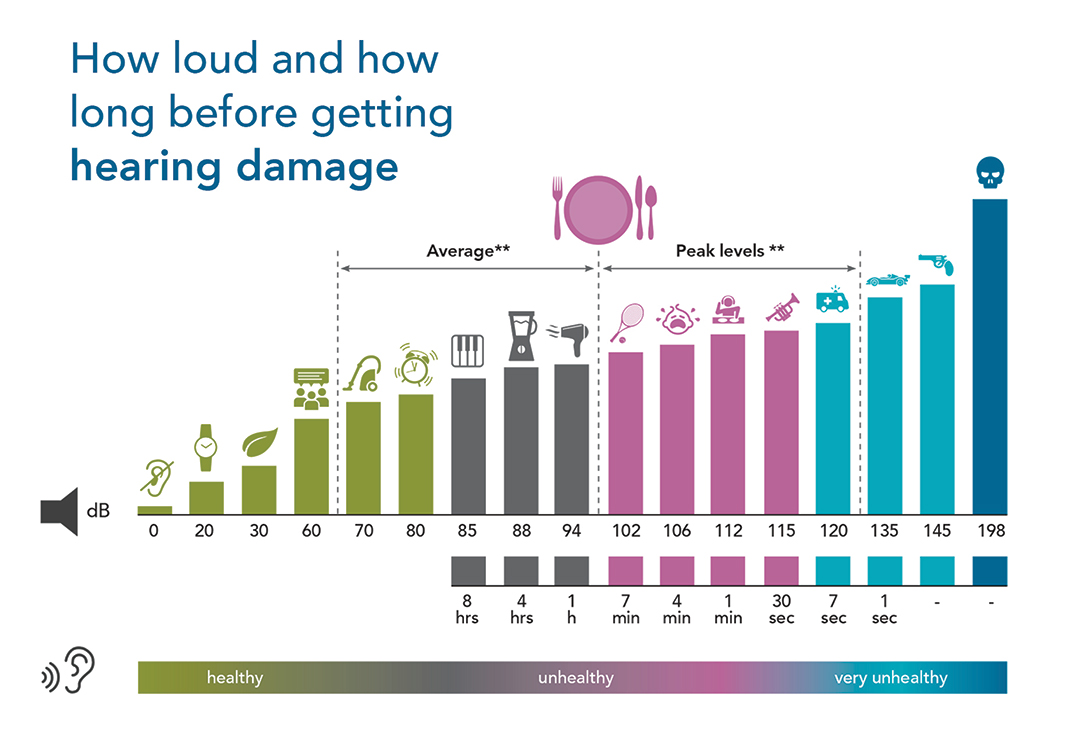

The effects of noise exposure on the health and well-being of building occupants can be serious and profound (see Figure 1). For instance, in commercial buildings, high levels of noise can interfere with communication and concentration, be responsible for a reduction in productivity, create physical and psychological stress, contribute to workplace accidents and injuries by making warning signals difficult to perceive, and even increase the risk of cardiovascular diseases.

In fact, the National Institute for Occupational Safety and Health says each year, 22 million U.S. workers are exposed to hazardous noise levels, which are sounds that exceed the time-weighted average of 85 A-weighted decibels (dBA) over a typical eight-hour workday. NIOSH also says occupational hearing loss, which is permanent, is one of the most common work-related injuries. So it is not surprising that most respondents to a study conducted by the Center for the Built Environment were not satisfied with their buildings’ acoustic performances and the dissatisfaction was highest regarding sound privacy.

To resolve this growing issue and devise effective strategies to improve the acoustic performances of commercial buildings, it is necessary to understand, at minimum, some of the fundamentals of sound transmittance and building acoustics.

Sound blockage and loss

Sound is a pressure wave created by a vibrating object that sets particles in air, gas, liquids or solids in vibrational motion, transporting energy through them. As a sound wave travels, it gradually loses energy, and the sound level decreases.

There is a wide range of pressure variation from the weakest to loudest sound a human ear can hear. This amplitude of a sound wave is measured in decibels (dB) and perceived as loudness. The frequency of a sound wave is expressed in units of hertz (Hz), sometimes referred to as pitch. The lower the frequency of a sound wave, the fewer the oscillations.

When sound encounters a structure such as a roof, various properties of the sound and structure influence how well the structure blocks its passage. For instance, a lower frequency sound (defined as a sound with a frequency of 500 hertz or less) has a long wavelength and is difficult to control. This is because such a sound wave transfers less energy to the medium it is traveling through, resulting in a slower loss of energy in the process. Community noises, including aircraft and vehicles, typically range between 50 hertz and 5,000 hertz.

A common way to increase a structure’s sound-blocking ability is to increase the weight of the materials that constitute it or their thickness. But homogenous material typically increases in stiffness as thickness increases, which can introduce two weaknesses. The first weakness, typically observed at a low frequency, is resonance (the frequency at which the structure tends to want to vibrate if excited). The second weakness, known as a coincidence dip, typically is observed at a higher frequency and occurs at the frequency at which the bending wavelength in the structure equals the sound’s wavelength.

In large commercial buildings, noise traveling from the exterior to interior can be blocked by using heavy, thick, monolithic construction, such as concrete, but it is not always practical or desired because many building assemblies use lightweight steel or wood framing.

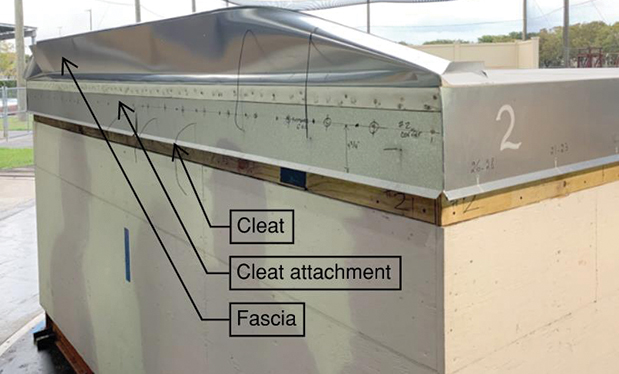

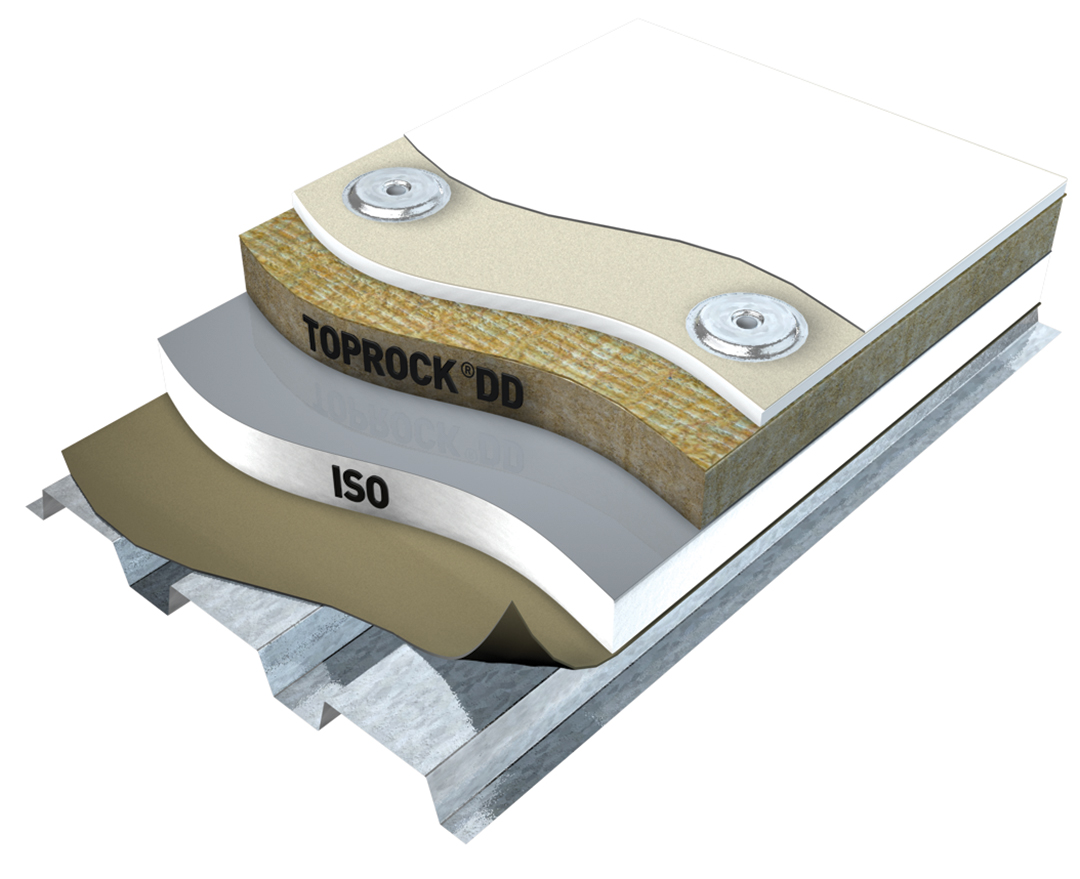

As a result, a common, efficient way to improve sound-blocking ability without greatly increasing weight is to create a cavity construction, which can be filled with a porous absorber (a sound absorptive material) between two layers of solid material. This can be done, for instance, by introducing one or several layers of stone wool insulation between a roof deck and cover board or the roof deck and the interior finishes between the roof structural members (see photo).

Another possibility is to introduce flexible connections, such as resilient channels or resilient sound-isolation clips, between the various layers of the system. In a commercial roof system, this could be done on the ceiling side.

The acoustic performance of a roof assembly can be evaluated in a laboratory typically in accordance with ASTM E90, “Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements.” The outcome of this test results in multiple transmission loss measurements.

To simplify the assessment of acoustic performances of roof assemblies and allow for overall comparisons, two single-number ratings were developed. The first, the Sound Transmission Class, is calculated by comparing the measured sound transmission loss to a reference contour curve at 500 hertz in accordance with ASTM E413, “Classification for Rating Sound Insulation.” The second, the Outdoor-Indoor Transmission Class, is calculated in accordance with ASTM E1332, “Standard Classification for Rating Outdoor-Indoor Sound Attenuation.”

As described in ASTM E413, the intent of STC is to “correlate in a general way with subjective impressions of sound transmission for speech, radio, television and similar sources of noise in offices and buildings.” Although it is used to compare roof assemblies, STC was developed to rate partitions and is not appropriate for sound sources such as outdoor noises that include strong low-frequency sounds. For this reason, it is preferable to consider the OITC rating with roof assemblies; it is a better representation of the sound insulation provided by an exterior roof. It is calculated over a frequency range of 80 to 4000 hertz. Similar to the STC rating, the higher the OITC rating number, the better the noise isolation.

Insulation

From a sound perspective, low-slope roof assemblies can play a role because unwanted noise also originates from air traffic, roof-mounted HVAC systems, rain, hail, etc.

Low-slope roof assemblies require careful design consideration to maximize acoustic performance not only around airports and flight paths but also for buildings where sound control is considered integral, such as sound stages, schools, hospitals, hotels, residential buildings or senior care facilities.

Furthermore, in modern urban areas, commercial and residential spaces also are often mixed or closer together, so containing sound in the commercial space may also be an important objective. A porous material such as stone wool insulation and, more specifically, a dual-density stone wool roof insulation board can be used as a sound-attenuating layer either by itself or as a facing to a solid barrier. As a porous layer, it contributes to sound attenuation partly by reflecting sound and partly by converting sound energy into heat as sound waves travel through the material. This type of stone wool product can absorb sound energy by damping the oscillation of the air particles because of its density and air-flow resistance.

During the years, manufacturers of insulation, roof membranes, gypsum cover boards and other products have used external, independent testing laboratories to evaluate numerous roof assemblies that incorporate, for instance, stone wool insulation over metal decks of various gauges and below roof membranes or standing-seam metal roofs. This information, which typically is published by manufacturers and sometimes summarized in acoustic catalogues and brochures, can be used to select the adequate system for a project based on the specific STC or OITC rating desired.

Addressing acoustic performance as early as possible during a project’s design phase will allow for a more optimized and cost-effective design. Because the acoustic requirement rarely is the sole objective, opting for a noncombustible stone wool insulation in a roof assembly also may contribute to fire safety requirements. Alternatively, a roof with a hybrid insulation strategy could provide passive fire protection, excellent acoustic performance and added thermal performance while minimizing roof assembly height if a structure is limited in the weight it can carry or in instances where there are specific height limitations. A hybrid insulation assembly is achieved by using stone wool as an insulating cover board or the thermal barrier over a layer of foam insulation such as polyisocyanurate.

The most common strategies to improve the acoustic performance of a roof assembly are:

- Adding mass. Mass improves a roof assembly’s sound attenuation because mass resists sound energy. The use of dense gypsum board is a common way to do this effectively.

- Adding absorptive materials. These materials absorb sound energy as sound waves travel through a roof assembly. Stone wool insulation is a good example of an absorptive material.

- Decoupling. This approach removes the rigid connections between the layers of materials that create a path for sound vibrations to easily travel. Decoupling can be achieved, for example, by selecting an adhered system over a fully mechanically fastened one.

Following these principles, the assemblies in the photos illustrate some incremental steps to improve roof assembly performance. Note architecture and design teams should consult with manufacturers and their technical teams for solutions to meet specific performance goals.

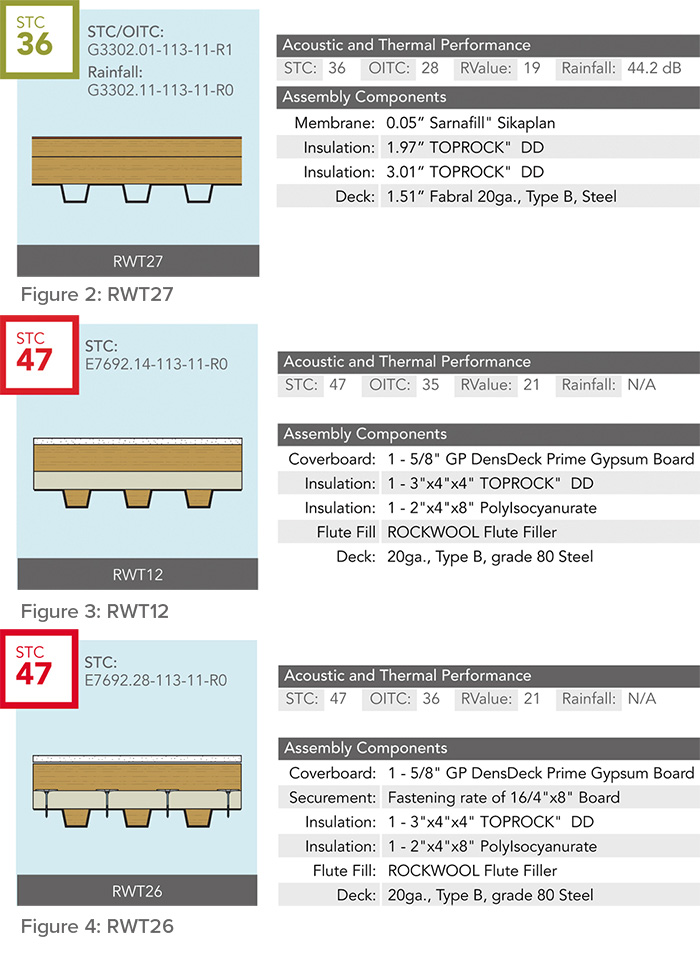

Let’s consider assembly RWT27 in Figure 2 as a basic design. It achieves moderate STC and OITC ratings of 36 and 28, respectively. This assembly does not include fasteners; with fasteners, the ratings would be lower.

Now, look at assembly RWT12 in Figure 3. By adding mass to the system using a gypsum cover board, increasing the amount of absorptive insulation and adding flute fillers in the corrugation of the deck, the STC rating increased 11 points, and the OITC rating significantly increased seven points. In fact, it is possible to fasten some of the bottom layers without affecting overall performance. This is demonstrated by assembly RWT26 in Figure 4 with its fasteners sandwiched between the insulation layers to prevent bridging. Longer fasteners penetrating fully through the assembly would decrease its rating several points.

Increasing performance even further is easy to achieve by adding more mass, such as by adding an additional layer of gypsum board above the flutes and/or secondary layer of cover board, as well as increasing insulation thickness. Stone wool insulation can help improve acoustic and thermal performance; adding additional polyisocyanurate in a hybrid stone wool assembly primarily contributes to increasing R-value, and its contribution to acoustic performance is less significant.

Case studies

Roof assemblies incorporating stone wool insulation have been specified for acoustic performance and to meet other performance objectives in a wide variety of high-performance buildings.

One example is when Flynn Canada, London, Ontario, turned a warehouse into an office space, but the noise from the nearby airport needed to be addressed. The new roof assembly, which incorporated a dual-density rigid stone wool insulation board product featuring a higher density top layer, provided a strong point-load resistance and higher mechanical properties as shown in Figure 5.

Valcoustics, Richmond Hill, Ontario, an acoustical consulting company, performed acoustical testing on the building before and after the reroof to assess the difference in noise transmission. Based on the same sound level at the roof for the pre- and post-renovation condition, Valcoustics measured the indoor noise criteria level was reduced from 61 to 39, and the indoor sound level dropped from 58 dBA to 45 dBA. This reduction was determined to be a direct result of the insulation.

Another example involved Lionsgate Studios, a 1-million-square-foot campus of stages, offices, support space and city street backlots in Yonkers, New York. It is one of the largest dedicated video and film production facilities on the East Coast. In 2021, with the construction of the second sound stage underway, TV crews working in the first completed studio space began noticing noise coming from the nearby train station. It was distracting enough inside the sound stage that filming had to pause regularly. Therefore, a new approach was decided for the roof of the second sound stage because the roof was identified as one of the weak points for sound transmission.

To address this issue, it was recommended to use multiple layers of gypsum board to add mass, a flute filler to insulate the metal deck and level the metal roof, as well as dual-density rigid stone wool insulation board for sound absorption and to reduce the rigidity of the connection between the interior and exterior of the roof by adhering the top layer of gypsum board and the membrane. This allowed the fasteners to be installed in the layers below (preventing bridging).

Using computer modeling and existing test data, the roof was estimated to have an STC rating of 55, which met the client’s demanding requirements for this challenging site (though it would have been beneficial, the OITC rating was not evaluated).

A holistic approach

Stone wool insulation can improve the acoustic performance of commercial low-slope assemblies. It provides excellent acoustic characteristics, but additional considerations such as adding mass and decoupling are just as critical to controlling sound and creating an effective roof system.

A key feature reducing sound transmission is the use of a cavity, or air gap, combined with acoustic insulation. Air gaps effectively “decouple” the main components from each other, diminishing the ability of sound to easily transmit through the full roof assembly. The use of resilient channels or other isolators also is a common technique to aid in decoupling and limit sound transfer, which can easily be implemented on a roof system’s interior side. Although gypsum is a popular material to block sound within rooms, acoustic ceiling tiles can offer a lighter-weight solution that provides the benefit of adding sound absorption.

Antoine Habellion, P.Eng., M.Eng, M.S., is technical director for ROCKWOOL, Milton, Ontario, Canada.