Fall-protection requirements set by the Occupational Safety and Health Administration (OSHA) have been part of the construction landscape since the early 1970s. The basis of the rules always has been that it is your obligation as an employer to provide a safe work environment for your employees regardless of the hazard or its origins. Ordinarily, what this has meant for roofing contractors is they must consider every job site's unique characteristics and minimize or eliminate fall hazards while weatherproofing a structure. The methods employed to do so historically have been temporary—installed for a particular job but able to be dismantled and used on the next job. Guardrails, warning lines and scaffolding are examples of such temporary methods.

Recent equipment manufacturing trends, as well as initiatives from the building design community and some building owners, may indicate future advancements for fall protection in the construction industry. One such advancement is permanent fall-protection anchors. Designers are starting to include them, and more building owners have been convinced of the benefits of having them installed on their buildings.

Building codes

Although OSHA law focuses on employers, other stakeholders who recently have received attention in eliminating or reducing worker exposures to falls are building owners, facility managers, designers, and state and local government building department representatives. Roofing contractors long have expressed the view that fall hazards from elevations can be reduced through building code modifications that require, for example, minimum parapet walls of 39 inches, caging over skylight domes or integrated permanent anchors.

Several jurisdictions are beginning to move toward making anchor points permanent. For example, Winter Park, Colo., has adopted provisions of the International Building Code (IBC) to govern building construction in the town. IBC does not have a provision regarding permanent fall-protection anchors. However, in March 2003, Winter Park amended its building code by ordinance to add a requirement for the installation of permanent fall-protection anchors on any building constructed in the town. According to the ordinance, anchors must be arranged so a person could not fall more than 6 feet or contact a lower level.

Similarly, Washington state has adopted IBC as the basis for its building code, and its legislature occasionally adds provisions to supplement IBC. In 1999, the legislature asked the Washington State Building Code Council (WSBCC) to study a proposal requiring permanent fall-protection anchors on all new structures and existing structures when a roof is replaced. WSBCC issued a report to the legislature about the effect of mandatory permanent fall-protection anchors, but no further action has been taken with regard to its findings.

The Construction Advisory Committee to Oregon OSHA includes representatives from labor, employers, trade organizations and government agencies who hope to strengthen the partnership between Oregon OSHA and the private sector. As part of its stated mission to address safety issues affecting the construction industry, the group supports the introduction of a building code amendment in Oregon that requires permanent anchors on roofs. Oregon enforces IBC for many building classifications and maintains a separate code for residential structures. Neither currently has a provision for permanent fall-protection anchors.

From a building owner's perspective, academia appears to be taking the lead on this issue. Fall-protection design guidelines for the University of North Carolina at Chapel Hill and University of Washington, Seattle, require permanent fall-protection anchors on new structures and when existing structures are reroofed. The protocols for each university also demand fixed screenings or railings for skylight openings.

The preceding examples, though clearly not indicative of a huge trend toward design-mandated, permanent fall-protection anchors, show the design approach to fall-protection issues gradually may be taking hold.

Products

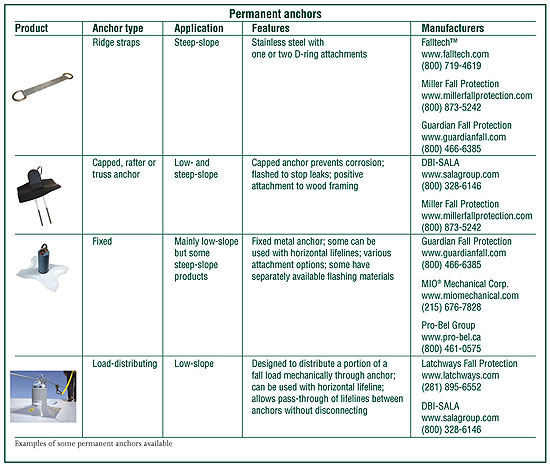

So what are some options for building owners, facility managers and roofing contractors looking to install permanent fall-protection anchors in a variety of applications? Products range from simple ridge anchors for steep-slope applications to anchors with sophisticated installation and flashing requirements for low-slope roofs. Many of the latter type are designed to allow a worker's lifeline to travel through multiple anchor points without the need to unhook and reconnect, giving the worker the freedom to move over a wide area and never lose the protection of being connected to the anchor.

Manufacturers of some permanent anchors require periodic maintenance and inspections of the anchor and related system equipment to ensure proper operation. Most products come with specific limited warranty language. Installation of some anchors must be done by workers who have been certified by particular manufacturers in correct attachment and placement procedures. This may provide business opportunities for roofing contractors, who are a natural choice to install anchors during roof system application.

OSHA requires that anchors used for attachment of personal fall-arrest equipment support 5,000 pounds per attached employee or be designed and installed under the supervision of a qualified person and part of a complete system that maintains a safety factor of two. OSHA's nonmandatory guidelines for personal fall-arrest systems under Appendix C to Subpart M (29 CFR 1926.500 et. al.) provide limited direction, and many other issues related to permanent fall-protection anchors remain unresolved by OSHA.

For instance, what procedures must be established to test permanent anchors when first installed and at other intervals during their useful lives and who must perform the tests? Some would argue a structural engineer is the appropriate person to approve anchor installations and approval must be granted before the anchor is weatherproofed.

Is compliance with a manufacturer's installation and maintenance procedures for permanent anchors sufficient for OSHA compliance, or would a more formal procedure similar to elevator inspections be preferred? Would installing permanent anchors void the manufacturer's warranty? What procedures should a roofing contractor follow before allowing workers to tie off to existing permanent anchor points? Direction may be provided by the ANSI I-14.1 standard developed by the International Window Cleaning Association. This standard provides testing, inspection and certification requirements for window-cleaning operations, including anchors.

Still searching

These questions and others certainly must be explored further before you can make informed decisions about installation and use of many permanent fall-protection anchors. NRCA and RCI Inc.—The Institute of Roofing, Waterproofing and Building Envelope Professionals recently formed a task force on safety design to discuss these issues and educate and influence construction industry groups about the value of design-generated solutions to fall protection. Input from all interested groups is welcome in an effort to make worker safety a design element of every structure.

Harry Dietz is NRCA's director of risk management.