NRCA has just completed limited testing of nail pull-out resistances in plywood and oriented strand board (OSB) roof sheathing. The purpose of the testing was to determine the influence specific fasteners and sheathing thicknesses have on the pull-out values for nails used to attach asphalt shingles.

Testing

NRCA obtained sheets of three thicknesses of plywood sheathing and three thicknesses of OSB sheathing for the testing. All the sheathing was obtained through typical distribution sources and labeled as being exterior-grade, performance-rated products suitable for roof sheathing applications.

NRCA also obtained quantities of two commonly available 1 1/2-inch- (38-mm-) long, hand-driven shingle nail types: a ring-shank shingle nail complying with ASTM F1667, "Standard Specification for Driven Fasteners: Nails, Spikes and Staples," and commodity-grade, smooth-shank shingle nail.

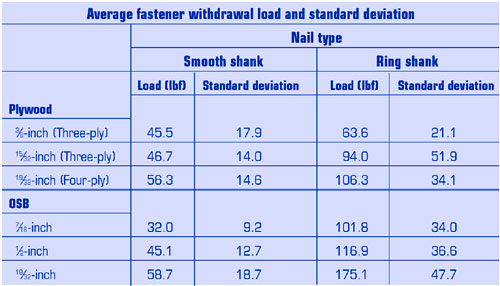

The sheathing samples were conditioned to standard laboratory conditions; test specimens were prepared; and nail pull-out testing was conducted according to ASTM D1761, "Standard Test Methods for Mechanical Fasteners in Wood." The results of the testing are shown in the figure.

The reported loads are averages of a minimum of 20 specimens tested for each sample. To calculate the metric equivalents, multiply load (lbf) by 4.45 to achieve Newtons.

Review of the test results reveals the pull-out values increase with the thickness of the sheathing tested and ring-shank nails provide noticeably higher pull-out values than smooth-shank nails. Also, though the pull-out values for the smooth-shank nails nearly are identical for similar thicknesses of plywood and OSB, the rink-shank nails provide substantially higher pull-out values in OSB.

In evaluating this data, it is important to realize these values apply only to the particular sheathing and fasteners tested. The values should not be used for design purposes. Specific design values are provided in the American Forest & Paper Association/American Wood Council's National Design Specification® (NDS) for Wood Construction.

Recommendations

The testing illustrates the importance of specific roof sheathing type and thickness and nail type in the pull-out resistance of nails used to attach asphalt shingles. For this reason, NRCA makes specific recommendations regarding roof deck sheathing and fasteners used in asphalt shingle roof assemblies.

NRCA recommends the use of a minimum of 15/32-inch- (12-mm-) thick (1/2-inch [13-mm] nominal thickness) exterior-grade plywood or OSB. Plywood roof sheathing is recommended to be labeled for compliance with U.S. Product Standards PS 1-95, "Construction and Industrial Plywood."

OSB sheathing is recommended to be labeled for compliance with PS 2-92, "Performance Standard for Wood-based Structural-use Panels" or The Engineered Wood Association (APA) standard PRP-108, "Performance Standard and Policies for Structural-use Panels."

For shingle nails, NRCA recommends 11- or 12-gauge galvanized steel or similar corrosion-resistant roofing nails with 3/8-inch (10-mm) head size and shanks that are barbed, ringed or otherwise deformed for added pull-out resistance.

Nails should be long enough to penetrate through all layers of roofing materials and the underside of sheathing or penetrate at least 3/4 of an inch (19 mm) into wood plank or board decks. Nails should comply with ASTM F1667, Type I, Style 20.

Mark S. Graham is NRCA's associate executive director of technical services.