Because polyisocyanurate insulation manufacturers recently changed how they determine and report thermal-resistance properties for their products, there now is an additional set of R-values being associated with polyisocyanurate insulation products. This has caused some confusion in the marketplace, and I will attempt to explain and clarify the situation.

Background

On Jan. 1, polyisocyanurate insulation manufacturers began to use the long-term thermal resistance (LTTR) method for determining and reporting thermal-resistance properties of permeable-faced polyisocyanurate insulation products. (For additional information, see "An end to a debate?" November 2002 issue.)

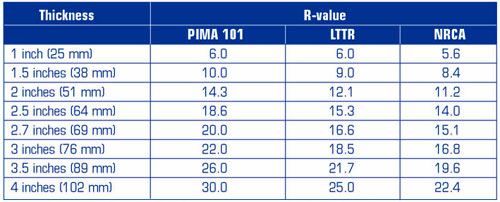

Previously, polyisocyanurate insulation manufacturers typically tested and reported R-values for their products using PIMA 101, "Roof Insulation Specimen Conditioning Procedure" (previously RIC/TIMA 281-1), which is a six-month conditioning procedure for reporting R-values.

Since 1987, NRCA has recommended designers and other affected parties use an R-value of 5.6 per inch of polyisocyanurate foam thickness as a reasonable guide when calculating the thermal performance of polyisocyanurate insulation boards over a typical roof system's life span. This recommendation is based on research that was reported in a November 1987 joint NRCA and Midwest Roofing Contractors Association technical bulletin, "In-service R-values (ISR) for polyisocyanurate and polyurethane roof insulation boards."

A comparison of the resulting R-values derived from these three methods is provided in the figure.

Comparison of R-values for faced polyisocyanurate insulation boards

NRCA's view

Although NRCA is encouraged by the technical development of LTTR methodology, NRCA is standing by its longstanding recommendation for determining in-service R-values for polyisocyanurate insulation products on the basis of 5.6 per inch of polyisocyanurate foam thickness.

NRCA maintains its recommendation because an adequate amount of data has yet to be provided to support LTTR values for specific polyisocyanurate insulation products. To date, only a limited amount of LTTR data has been made available based on Canadian-manufactured polyisocyanurate insulation using third-generation hydrocarbon-based blowing agents.

Also, the LTTR data that have been provided only are based on a 75 F (24 C) mean test temperature. This temperature is not necessarily indicative of the temperature range under which rigid board insulation products are expected to perform.

The U.S. material standard for polyisocyanurate insulation (ASTM C1289, "Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board") includes requirements for reporting R-values at 40 F, 75 F and 110 F (4 C, 24 C and 43 C) mean test temperatures. For second-generation polyisocyanurate insulation products using an HCFC-141b blowing agent, products' R-values at 40 F and 110 F (4 C and 43 C) mean test temperatures varied from those tested at 75 F (24 C).

At this point, the R-values of third-generation polyisocyanurate insulation products tested at temperatures other than 75 F (24 C) are not widely known.

Closing thoughts

Because three methods of determining and reporting R-values for polyisocyanurate insulation currently exist, some confusion regarding this issue likely will continue.

When designing roof assemblies using polyisocyanurate roof insulation, designers should base their designs on the R-value method they believe is most appropriate. When specifying polyisocyanurate roof insulation, I encourage designers to identify these products by their thicknesses, not solely their R-values.

Mark S. Graham is NRCA's associate executive director of technical services.