This month, U.S. polyisocyanurate insulation manufacturers begin reporting long-term thermal resistance (LTTR) values based on updated and revised test methods, resulting in lower LTTR values than previous values. Does this change settle a decades-long debate regarding R-values for polyisocyanurate insulation?

Background

The R-value of closed-cell, polyisocyanurate insulation is affected by the amount of gas in the foam's cells. Because the R-value of most blowing agents (gases) is greater than that of air, polyisocyanurate insulation's R-value is greatest when there is more blowing agent and less air in the foam's cells.

During polyisocyanurate insulation's service life, air diffuses into the foam's cells and the blowing agent diffuses out or partially dissolves into the cell's polymer matrix.

Because of this phenomenon, the R-value of polyisocyanurate insulation is not constant. Its R-value is highest soon after manufacturing and decreases at a relatively significant rate during the earliest portion of its service life. As polyisocyanurate insulation ages further, its R-value decreases at a slower rate until the gas concentration in the foam's cells equals the gas concentration in air, at which point its R-value no longer changes with time.

In 1987, based on extensive testing of in-service R-values, NRCA and the Midwest Roofing Contractors Association issued a joint technical bulletin regarding the in-service R-values of polyisocyanurate and polyurethane insulation. The bulletin recommended using an in-service R-value of 5.6 per inch of foam thickness. This in-service R-value is intended to account for polyisocyanurate insulation's R-value losses over time and provides a more realistic design R-value for polyisocyanurate insulation during a roof system's entire design life.

Analyzing LTTR

The LTTR test method, ASTM C1303, "Standard Test Method for Predicting Long-Term Thermal Resistance of Closed-Cell Foam Insulation," defines "long term" as five years. LTTR testing involves accelerated aging under controlled laboratory conditions, meaning 75 F.

The design service life for most roof systems is longer than five years as 20-year and longer roof system guarantees now are commonplace. Also, rooftop temperature conditions typically vary significantly from laboratory conditions. Therefore, LTTR is not representative of actual rooftop conditions.

NRCA recommendations

In 2005, NRCA participated in a limited testing program that showed a majority of polyisocyanurate insulation samples tested one to four years after manufacturing had actual R-values less than their LTTR values.

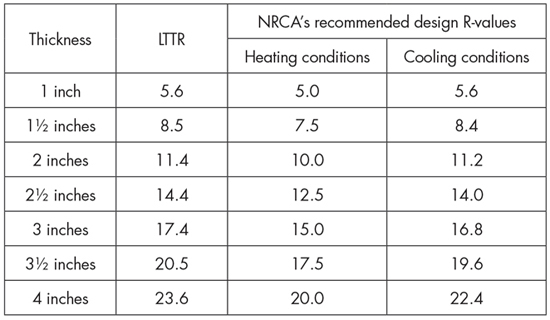

Comparison of current LTTR values and NRCA's recommended design R-values

In 2009, NRCA conducted R-value testing of polyisocyanurate insulation obtained through distributors; samples ranged in age from four to 13 months. R-values were tested at a 75 F mean reference temperature as well as 25 F, 40 F and 110 F and found to be less than their published LTTR values.

In 2011, with the publication of The NRCA Roofing Manual: Membrane Roof Systems—2011, NRCA revised its 1987 design R-value recommendation to account for polyisocyanurate insulation's different R-values at different temperatures. The figure compares polyisocyanurate insulation manufacturers' current LTTR values with NRCA's recommended design values.

In 2013, Building Science Corp., Somerville, Mass., a building science consulting and architecture firm, published Information Sheet 502, "Understanding the Temperature Dependence of R-values for Polyisocyanurate Roof Insulation," which replicated NRCA's 2009 testing with similar results.

Whether designers use LTTR or NRCA's predominant temperature condition-based design R-values, NRCA recommends designers specify polyisocyanurate insulation by its desired thickness rather than its R-value or LTTR to avoid possible confusion during procurement.

Mark S. Graham is NRCA's associate executive director of technical services.