The cost of doing business can be calculated in different ways. For roofing contractors, workers' compensation insurance always has extracted a heavy toll. As a result, you should be aware of trends—positive and negative—and adjust your company's safety program accordingly.

Workers' compensation

Some encouraging results, including rate reductions, are beginning to emerge from states that have adopted workers' compensation insurance reforms, such as California, Florida and Tennessee.

Claim frequency continues to decline in the U.S. for workers' compensation injuries—mostly for small claims. However, severity in dollars of medical claims continues to rise.

Medical costs continue to rise sharply—10.5 percent in 2004 compared with 2003 levels.

How should you control risk and effectively manage the related costs in the current environment? One solution is to create and maintain safer job sites. Identifying the factors that contribute to roofing workers' risk exposure is a critical first step.

Manual material handling

Injuries from manual material handling mishaps and falls represent more than 50 percent of claim costs involving lost time. Programs that effectively control these loss drivers and lower risk exposure can increase your profitability.

Most manual material handling accidents can be prevented with proper planning. But hazards must be identified and remedied at the beginning of a job. If a job is properly planned, the foreman and roofing workers at the job site are better-equipped to make decisions about effective controls.

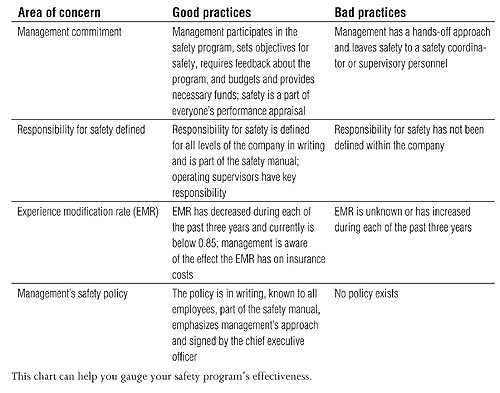

This chart can help you gauge your safety program's effectiveness.

In the roofing industry, lifting is a known manual material handling risk factor. The U.S. Bureau of Labor Statistics reported in 2003 that there were 340,000 overexertion injuries; more than half were specifically associated with lifting.

Back- and joint-related pain among workers is a major factor in the roofing industry's high turnover rate. These injuries can force quality workers to retire from roofing or find alternative occupations.

With regard to lifting, the first question you should ask is whether a load needs to be moved at all. Eliminating unnecessary tasks can reduce risk and provide greater efficiency. Also, reducing the number of times a load is handled can result in less risk to employees and loads and improved efficiency.

You can gauge the effectiveness of your safety program by using the methods described in the figure.

Prevention

Preparing for common hazards can help you prevent accidents on job sites. Commitment to safety is a key component. For more information about safety programs, please see NRCA's product catalog at shop.nrca.net or consult your insurance agent and carrier.

Leslie Kazmierowski is NRCA's insurance programs manager.