The Kankakee Welcome Center off Interstate I-65 Southbound in Roselawn, Ind., is the first of a 10-year, $276 million plan to replace the rest stops at all entry points to Indiana, each representing unique features of the region in which they are located.

The $35 million state-of-the-art facility spans 11,304 square feet and features interactive tourism displays, walking trails and a large monarch butterfly exhibit. Situated around natural wetlands, the center includes a large retention pond with a walkway, playground, a dog walking area and 150 parking spots for semi-trucks.

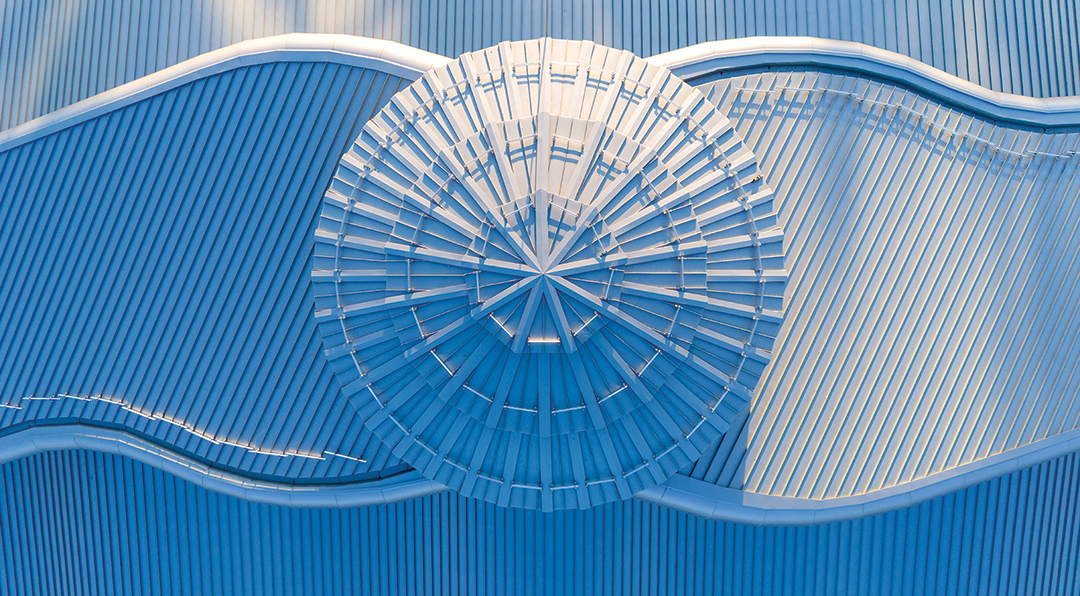

Designed by Fosse and Associates, Evansville, Ind., the welcome center’s most notable feature is a curvy roof meant to represent the many dunes in the area. Korellis, Hammond, Ind., was selected as the roofing contractor to install the facility’s unique standing-seam metal roof system.

All the details

The Korellis team began work on the Kankakee Welcome Center in December 2022. The project consisted of the main welcome center, shelter areas and outbuildings. Korellis’ scope of work included installing roof systems on multiple slopes and shapes, flashings, inlaid gutters, custom fascia, trim and soffit over a 16,700-square-foot roof area.

To build the roof, the team installed two layers of plywood for the deck and mechanically attached two layers of 2-inch Dupont Styrofoam™ Brand Extruded Polystyrene Foam Insulation followed by Carlisle WIP® 300HT self-adhering underlayment and .040-inch-thick PAC-CLAD® Tite-Loc Plus aluminum standing-seam panels.

The roof panels were fabricated by Petersen Aluminum Corp., Elk Grove Village, Ill., and curved in the field to match roof profiles.

“Each roof line differed from convex to concave shapes,” says Larry Millefoglie, estimator and project manager for Korellis. “Each step of construction and verification of each trade’s completion was essential before we were able to start the next section of roofing.”

Because of the roof’s unusual shape, many of the flashings, fascia, trim and closures were custom-fabricated by Korellis craftsmen in the company’s sheet-metal shop or on-site to ensure proper fitting and alignment. Measuring and fabricating the custom pieces took as much time as installation.

“It took more than 6,500 man-hours just to fabricate the fascia as each area was more challenging than the previous,” Millefoglie says. “The fascia metal pieces were custom-bent in-house to accommodate radius, concave and convex perimeters that began the basis of our starting points for all combined roof areas.”

Korellis craftsmen trimmed the metal for the fascia on-site to accommodate the curved wood substrate while remaining watertight and aesthetically pleasing.

In addition, the Korellis team installed wall cladding and snow guards made from aluminum composite materials.

“The wall panels along with inset gutters were installed in a way so the roofing materials are able to function together, ensuring watertightness throughout the entire roof system,” Millefoglie says. “Our team not only displayed extraordinary professionalism and safety, but we also exhibited remarkable craftsmanship.”

Challenges

The Kankakee Welcome Center roofing project was filled with details and challenges.

“The roof system consisted of exposed conduit, so we had to cut the insulation to ensure the wood did not penetrate the conduit,” Millefoglie says. “The aluminum composite material changed direction and size, and we had to modify it to ensure proper fitting. The wood required being cut specifically for the installed dome section. The upper roof panels had to be set to 20-degree angles versus 90-degree. And the lower panels rolled left to right as well as at a 3:12 slope.”

In addition, safety measures changed multiple times as the project progressed to ensure safety precautions and the well-being of the crew. To remain 100% tied off while installing the panels on the convex roof, team members used vertical and horizontal lifelines with standing-seam clamps.

“That ensured 100% safety among multiple crews and trades,” Millefoglie says.

Boom lifts ranging from 40 feet to 85 feet were used for portions of construction along with ladders and safety lifelines for full-restraint tie-off during installation.

Long lead times also posed some difficulty.

“Planning started during the material shortage and pricing escalations resulting from the COVID-19 pandemic,” Millefoglie says. “Korellis has always looked ahead and planned to provide great customer service. These challenges caused by the pandemic just meant we had to try harder and work together in the office and the field, which made us stronger as a team.”

Hoosier hospitality

In January 2023, the Korellis team completed work on the Kankakee Welcome Center. Although material delays and poor weather caused the project to be delayed a few weeks, Indiana’s landmark Welcome Center successfully opened to the public in October 2023 thanks to the Korellis team’s diligent attention to detail.

“The Kankakee Welcome Center is a show piece from the ground up,” Millefoglie says. “Being part of the project from start to finish as well as being part of the roofing team has been extremely rewarding.”

PROJECT NAME: Kankakee Welcome Center

PROJECT LOCATION: Roselawn, Ind.

PROJECT DURATION: Dec. 15, 2022-Jan. 10, 2023

ROOFING CONTRACTOR: Korellis, Hammond, Ind.

ROOF SYSTEM TYPE: Standing-seam aluminum

ROOFING MANUFACTURERS: DuPont,™ Wilmington, Del.; Petersen Aluminum Corp., Elk Grove Village, Ill., a brand of Carlisle Construction Materials, Carlisle, Pa.

CHRYSTINE ELLE HANUS is Professional Roofing’s associate editor and an NRCA director of communications.