North Manitou Shoal Light Station, known to locals as The Crib, is a lighthouse located in Lake Michigan southeast of North Manitou Island in Leland Township, Mich. Built in 1935, the North Manitou Shoal Light Station was the last manned offshore lighthouse in the Great Lakes before becoming automated in 1980. In 2005, the lighthouse was listed on the National Register of Historic Places.

After sitting vacant for 36 years, in 2016, North Manitou Light Keepers purchased the lighthouse from the U.S. Coast Guard at a public auction. North Manitou Light Keepers is a nonprofit organization with a mission of restoring the lighthouse landmark and opening it to the public for tours and overnight stays.

As part of lighthouse renovations, Doyle Inc. Roofing, Cheboygan, Mich., was selected by the project’s general contractor, Mihm Enterprises Inc., Hamilton, Mich., to design and install a new roof system that meets the Department of the Interior’s standards under the National Historic Preservation Act.

Exterior renovations

In 2017, North Manitou Light Keepers began its aggressive lighthouse restoration project that focused primarily on the exterior, which included sandblasting, painting, restoring and rebuilding windows, and replacing lantern glass.

Water intrusion at the mid-level deck caused structural and cosmetic damage to interior living quarters, requiring major exterior renovations.

“When the U.S. Coast Guard mothballed the lighthouse in 1980, 3/8-inch steel plates were installed on the mid-level deck to prevent water intrusion and secure the structure for long-term preservation,” says Dave McWilliam, chief of restoration and operations for North Manitou Light Keepers. “The plates were badly deteriorated and delaminated and had to be removed before a new roof membrane could be placed.”

As part of the project, about 7,300 pounds of steel were removed by the Mihm Enterprises team who cut the steel into pallet-sized pieces, lowered them to a workboat via crane and hauled the steel to shore to be recycled.

“Fortunately, the underlying concrete surface was in relatively good shape and required minimal repairs,” McWilliam says.

In mid-September 2022, Doyle Inc. Roofing began work on the lighthouse’s new 1,040-square-foot TPO membrane roof system.

New roof

North Manitou Shoal Light Station is located 9 miles from the closest marina in the middle of Sleeping Bear Dunes National Lakeshore, creating a host of challenges: unpredictable and swiftly changing weather; difficult access to the job site requiring all materials and workers to be transported via boat; and no electricity or functioning plumbing in the building.

In addition to complying with the Department of the Interior’s historical preservation standards monitored by Michigan’s State Historic Preservation Office, the roofing project required zero negative environmental impact on air and water quality, which also was closely monitored by government officials, adding complexity and project costs.

“The COVID-19 pandemic had a large effect on the project,” McWilliam says. “Initial pre-pandemic cost estimates were around $80,000. Unfortunately, because of the grant and funding process, the final specifications and requests for proposals were not approved until the COVID-19 pandemic labor and material shortages occurred. As a result, the project cost ballooned to $115,000. Material shortages and unavailability also delayed the project for nearly a year.”

For this unique roofing project, the roof includes a walkway surface on the lighthouse’s third level, where the Doyle Inc. Roofing crew leveled the concrete deck using cement grinders. Team members hand-carried all debris down two flights of stairs to the main level.

“All new material had to be loaded on a boat by hand and then transported to the lighthouse where Davit Cranes were used to lift materials to the main level,” explains Joel Ross, president of Doyle Inc. Roofing. “From there, all material had to be hauled by hand to the third level. Extreme weather and waves stopped us from reaching the lighthouse several times and forced us to be picked up from the lighthouse and brought back to the mainland early on some days.”

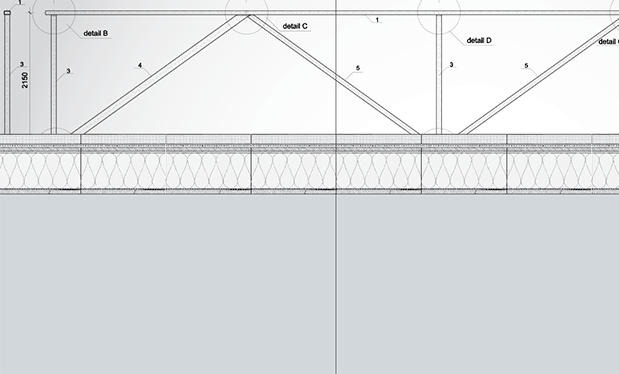

The lighthouse’s second-level roof has two drains, and all sides of the lighthouse have wall base flashing. The Doyle Inc. Roofing team recommended and installed an approved hybrid roof assembly from Versico Roofing Systems that included 1/2-inch-thick SecurShield® HD 100-psi polyisocyanurate insulation mechanically fastened with MP 14-10 Fasteners and adhered with Flexible DASH Adhesive.

On the walkway surface, team members used CAV-GRIP® 3V to adhere 135-mil-thick VersiFleece® TPO membrane in gray. At all walkway-to-wall transitions, team members adhered 60-mil VersiWeld® TPO membrane wall base flashings in white.

“This system provides the lighthouse with excellent protection against harsh weather and conditions,” Ross says. “It was accepted by the state architect and has a 15-year warranty. The gray color option replicates the lighthouse’s original concrete deck aesthetics.”

Back to light

Despite numerous logistical challenges and project requirements, the Doyle Inc. Roofing team completed its work on North Manitou Shoal Light Station in four days.

“The work from Doyle Inc. Roofing was high quality, and the support and warranty from Versico Roofing Systems was appreciated,” McWilliam says. “We also appreciated the coordination and cooperation between the teams at Doyle Inc. Roofing and Versico Roofing Systems to ensure the work was done to historical standards and met the approval of the state’s architect. All parties worked well together to ensure a successful project outcome.”

Thanks to Doyle Inc. Roofing’s dedicated five-person on-site team, a Michigan landmark was restored and historically preserved to serve the needs of the lighthouse and public for many years to come.

“Completing a job with so many challenges and overcoming all the obstacles thrown our way was truly rewarding,” Ross says.

PROJECT NAME: North Manitou Shoal Light Station

PROJECT LOCATION: Leland Township, Mich.

PROJECT DURATION: Sept. 12-16, 2022

ROOFING CONTRACTOR: Doyle Inc. Roofing, Cheboygan, Mich.

ROOF SYSTEM TYPES: TPO membrane

ROOFING MANUFACTURER: Versico Roofing Systems, Carlisle, Pa.

CHRYSTINE ELLE HANUS is Professional Roofing’s associate editor and an NRCA director of communications.