Penetration pockets, sometimes referred to as pitch pans or gum pockets, are best described as square- or rectangular-shaped sheet-metal boxes. Such objects typically are used to form weatherproof seals where irregular-shaped penetrations intersect the field of the roof system. These penetrations can range from circular to oval to U-shaped and be constructed with materials to which flashing materials cannot easily adhere.

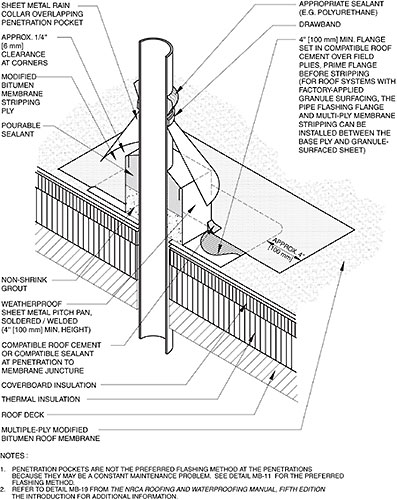

Currently, the material generally specified for penetration pockets is a minimum 26-gauge galvanized metal bent a minimum of 4 inches (102 mm) in height with exposed hemmed edges and fabricated with 4-inch (102-mm) minimum horizontal flanges extending outward to form a base so the pan can be installed on the roof membrane. The open metal sides are soldered to form a weatherproof seal. The pocket then is half-filled with a nonshrink cementitious grout to form a solid base around the projection and aid in preventing or blocking the semi-fluid pourable topping from running between the penetration and deck. The penetration pocket then is topped off with a pourable sealant compatible with the roof system or recommended by the roof membrane manufacturer.

Asphaltic and coal-tar-based built-up and modified bitumen roof system manufacturers stipulate the sheet metal used for penetration pockets be primed and set in a bed of the appropriate mastic before flanges are stripped in and flashed. Some single-ply thermoplastic membrane manufacturers require the use of membrane-coated metal instead of standard galvanized metal to promote better adhesion of the material flashing strips to penetration pockets.

Detail MB-19 from The NRCA Roofing and Waterproofing Manual, Fifth Edition.

The NRCA Roofing and Waterproofing Manual, Fifth Edition, offers section and isometric details of penetration pockets for built-up, modified bitumen, thermoset and thermoplastic roof membrane systems. NRCA's detail MB-19, "Penetration Pockets," provides visual information for constructing a penetration pocket in a modified bitumen roof system.

All these details incorporate the use of a sheet-metal rain collar overlapping the pocket.

Penetration pockets primarily are used when a penetration's shape cannot properly be flashed and counterflashed with appropriate materials or when economics dictate a simple solution.

NRCA's manual specifically states, "Penetration pockets are not the preferred flashing method at the penetrations because they may be a constant maintenance problem." Improper maintenance or a lack of maintenance inevitably will lead to water infiltration and leaks. Most roof system manufacturers take exception to penetration pockets in their warranties.