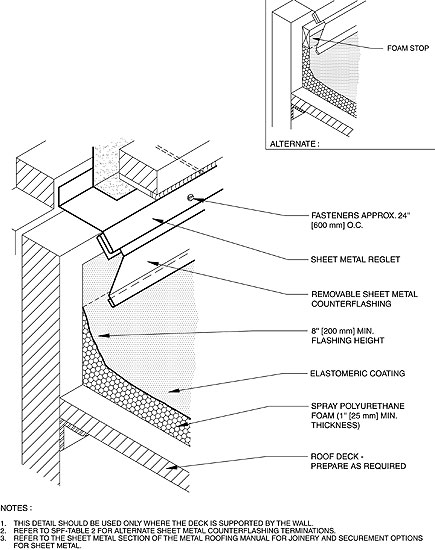

NRCA first provided technical information for spray polyurethane foam (SPF)-based roof systems in the fourth edition of The NRCA Roofing and Waterproofing Manual in 1996. There were 25 SPF-based construction details included. In the fifth edition in 2001, the text was updated and additional construction details were added. There currently are 32 SPF-based construction details-27 with elastomeric coating and five with membrane coverings, including SPF-5, "Base Flashing for Wall-supported Deck," which provides SPF flashing, metal reglet (also known as through-wall flashing) and counterflashing information (see figure).

The counterflashing is installed after the installation of spray polyurethane foam (SPF) and coating. The coating should extend about 2 inches (50 mm) above the foam's top edge, which should be 6 inches (150 mm) minimum in height, and the counterflashing ideally should cover the location where the foam terminates.

For the through-wall flashing to perform properly, the foam and coating must not cover the counterflashing, reglet and weep holes. Through-wall flashing is used where moisture is likely to penetrate the wall system. For example, masonry and stucco walls typically incorporate through-wall flashing at the interface of the roof flashing and wall covering. Through-wall flashing directs moisture that penetrates the wall system toward the roof surface, preventing the moisture from entering the building and decreasing possible deterioration of the substructure. The use of weep holes allows trapped moisture to escape the wall system. NRCA does not recommend sealing the joint between the through-wall flashing and wall covering; this reduces the ability for moisture to escape the wall system.

In the manual's fourth edition, the through-wall flashing and counterflashing were depicted with a 3-inch (76-mm) overlap seam; the through-wall flashing also included a single bead of sealant. SPF-5 in the fifth edition does not provide specific direction for joining the through-wall flashing and counterflashing. To accommodate the multiple accepted methods of joining sheet metal, a Sheet Metal section now is included in the Construction Details section of the fifth edition. Common joints are depicted in SM-26; the lap seam and cover plate seams are appropriate joinery methods for SPF-5, and NRCA recommends installing sealant in the laps of the metal. The through-wall flashing/sheet-metal reglet and weep holes typically are installed by a masonry contractor. The counterflashing is installed by a roofing contractor. The through-wall flashing and counterflashing material may be supplied by either.

COMMENTS

Be the first to comment. Please log in to leave a comment.