When specifying metal panel roof systems, roof system designers and specifiers need to be aware of specific standards. Sometimes, the standards applicable to metal panel roof systems are identical or similar to those that apply to other roof system types. However, in some cases, standards unique to metal products or metal panel roof systems apply.

Specifications

Two ASTM International standard specifications, ASTM E1514, "Standard Specification for Structural Standing Seam Steel Roof Panel Systems," and ASTM E1637, "Standard Specification for Structural Standing Seam Aluminum Roof Panel Systems," provide basic design guidelines for steel and aluminum structural standing-seam roof panel systems.

The two standards address weather protection, specified design loads and proper access over roof surfaces to provide for periodic equipment maintenance. Each standard addresses specific performance requirements (minimum design loads, thermal movement), structural integrity (load capacity), panel material, panel clips, anchorage and watertightness.

The American Iron and Steel Institute's North American Specification for the Design of Cold-Formed Steel Structural Members (AISI S100) provides a basis for analytical determination of load capacities for steel roof panels and clips without the need for load testing.

Similarly, The Aluminum Association's Aluminum Design Manual provides a basis for analytical determination of load capacities for aluminum roof panels and clips without the need for load testing.

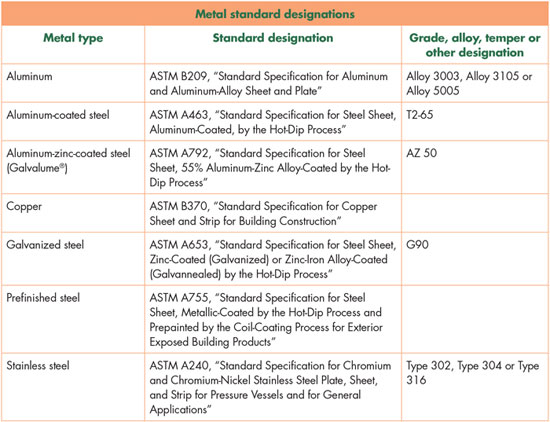

Standard designations applicable to various metals used in metal panel roof systems

ASTM E1514 and ASTM E1637 include nonmandatory appendices that provide additional roof system performance considerations, including guidelines for air infiltration and water-resistance testing.

Although ASTM E1514 and ASTM E1637 specifically address structural standing-seam metal panels, similar consensus-based standard specifications do not exist for architectural metal panel roof systems. Designers and specifiers can adapt some of the criteria from ASTM E1514 and ASTM E1637 to architectural metal panel roof systems.

Materials

Selecting the material from which metal panel roof systems are fabricated is an important consideration for designers and specifiers.

The standards applicable to specific metals commonly used in metal panel roof systems are provided in the figure.

In addition to specifying the specific material standard, it is important designers also indicate the grade, temper or coating designation desired. These are best determined based on a specific project's requirements and after consulting with metal suppliers and experienced roofing contractors.

Metal thicknesses are best determined by the specific project's requirements. Minimum design gravity loads and required wind-uplift loads often will dictate the necessary metal thickness and panel profiles.

Wind-uplift resistance

The methods for determining wind-uplift resistances for metal panel roof systems are dictated by the applicable building code. For example, the International Building Code (IBC) dictates metal panel roof systems be tested for wind-uplift resistances according to UL 580, "Test for Uplift Resistance of Roof Assemblies," or ASTM E1592, "Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference." UL 580 can be applied to metal panel roof systems installed over solid or closely spaced roof decks. ASTM E1592 applies to metal panel roof systems installed over open metal framing, such as structural metal roof panel systems.

IBC permits wind-uplift resistance of steel structural metal panel roof systems installed without a roof deck, such as directly over open metal framing, to be designed using AISI S100 without testing.

An additional test method, FM 4471, "Approval Standard for Class I Panel Roofs," sometimes is used to evaluate the wind-uplift resistance of metal panel roof systems, particularly for buildings insured by FM Global. FM Global also publishes Loss Prevention Data Sheet 1-31 (FM 1-31), "Metal Roof Systems." However, FM 4471 and FM 1-31 are not recognized in IBC.

Fire resistance

The applicable building codes also dictate the methods for determining metal panel roof systems' fire resistances.

Until the publication of the International Building Code, 2009 Edition (IBC 2009) metal panel roof systems generally were exempted from fire testing. Steel roof panels were deemed equivalent to Class A and aluminum roofs equivalent to Class B regardless of any underlying rosin paper, underlayment, insulation or combustible deck substrates.

Beginning with the publication of IBC 2009 and continuing to IBC's 2012 edition, metal panel roof systems now need to be fire tested similar to other roof systems. The code change was made because though metal roof panels generally resist flame spread, metal by its nature conducts and holds heat, which can contribute to the ignition of underlying combustible materials.

IBC 2009 and IBC 2012 require metal panel roof systems be fire tested according to ASTM E108, "Standard Test Methods for Fire Tests of Roof Coverings," or UL 790, "Standard Test Methods for Fire Tests of Roof Coverings." These are the same fire test classification methods that apply to other roof system types that result in Class A, Class B or Class C designations.

An exception in IBC 2009's and IBC 2012's fire classification requirements states: "… ferrous, copper or metal sheets installed without a roof deck on noncombustible framing," indicating many structural standing-seam metal panel systems installed without a roof deck are exempt from the codes' fire testing requirements.

In IBC 2012, an additional exception was added permitting "… minimum 16 oz/sq. ft. (0.014 kg/m2) copper sheets installed over combustible deck" to be considered equivalent to Class A without additional testing.

Hail impact resistance

Impact resistance from simulated hail typically is tested using UL 2218, "Impact Resistance of Prepared Roof Covering Materials." The testing results in classifications of Class I, Class II, Class III or Class IV with Class I being the least impact-resistant and Class IV being the most impact-resistant. The test method involves dropping steel balls of specified diameters and weights from defined heights and observing test specimens for evidence of cracking.

Because of the nature of metal panels, they generally will not crack when subjected to UL 2218. As a result, many metal roof panels tested will achieve the highest Class IV designation. However, though metal panels subjected to UL 2218 testing typically will not exhibit cracks, they will exhibit dents and other visual imperfections that most building owners will consider objectionable.

Therefore, simulated hail impact resistance testing, such as UL 2218, is not a good measure of metal panel roof systems' impact resistances.

Water leakage

Two test methods are sometimes used to test the water-tightness of metal panel systems: ASTM E2140, "Standard Test Method for Water Penetration of Metal Roof Panel Systems by Static Water Pressure Head," and ASTM E1646, "Standard Test Method for Water Penetration of Exterior Metal Roof Panel Systems by Uniform Static Air Pressure Difference."

With ASTM E2140, a test specimen consisting of at least three full panel widths (four side seams) by a multiple-span condition in length with at least two panel end laps is assembled and sealed into a watertight test frame apparatus. Then, about 3 inches of water are added over the roof panels and left in place for five minutes. Seams are observed from the bottomside of the test apparatus to monitor for leakage. Provided no leakage is observed, an additional 3 inches of water are added, making the total 6 inches, and left in place for a minimum of six hours. Seams are observed from the bottomside of the test apparatus to monitor for leakage. The test result is a pass/fail determination for seam leakage at the end of the six-hour period. The 6 inches of water used in the test are equivalent to about 31 pounds per square foot.

ASTM E2140 testing generally is considered to be applicable to structural standing-seam metal panel systems with in-seam sealant intended to be applied at slopes less than 2:12 (9 degrees).

With ASTM E1646, a test specimen of at least three full panel widths (four side seams) by a multispan condition in lengths with a minimum of three panel end laps is assembled and sealed into a test apparatus. An air pressure difference of at least 20 percent of the subject building's positive design wind pressure but no less than 6.24 pounds (force) per square foot is exerted across the test specimen while a water spray equivalent of 8 inches of rain per hour is applied. Roof panel seams are visually monitored for leakage during the 15-minute test. The result is typically a pass/fail determination of water leakage at the specific pressure differential exerted across the test specimen.

Air leakage

ASTM E1680, "Standard Test Method for Rate of Air Leakage Through Exterior Metal Roof Panel Systems," provides a method for determining metal panel roof systems' resistance to air infiltration resulting from either positive or negative air pressure differentials.

Using this test method, a test specimen for a particular metal panel roof system is installed and sealed into or against one face of an air chamber. Air is supplied to or exhausted from the chamber at a rate required to maintain a specified test pressure difference across the specimen. The amount of resultant air flow through the specimen is measured and reported as a rate of air leakage per unit area of the specimen.

The test method does not provide a specific pass/fail determination. Instead, the resultant air leakage rate per unit area can be compared with values specified by the project designer based on the project's specific conditions. Designers may specify maximum air leakage rates for specific building components, such as the roof system, or the entire building envelope.

ASTM E1680 is similar to ASTM E283, "Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen," which applies to buildings' façades.

It can get complicated

Although some standards applicable to metal panel roof systems are the same as those that apply to other roof systems, other standards are unique to metal products and metal panel roof systems. Metal panel designers and specifiers should be knowledgeable about these standards. Additional information regarding metal panel roof systems is contained in the metal panel roof system section of The NRCA Roofing Manual: Metal Panel and SPF Roof Systems—2012.

Mark S. Graham is NRCA's associate executive director of technical services.

What about contractor-fabricated panels?

For most roofing products used in the U.S., roofing professionals rely on product manufacturers to perform testing and provide the necessary compliance with applicable standards. However, because there are no product manufacturers for contractor-fabricated metal panel roof systems, the responsibility for providing such products' standard compliance information lies largely with the contractor who fabricates and installs the metal roof panels.

Most metal roof panel roll-forming equipment roofing contractors use produces panels of standard profiles and dimensions. In these cases, the standards applicable to the roll-forming equipment manufacturer's panel design may apply to the specific panels produced by roofing contractors using that roll-forming equipment. However, in some situations, the length of time the equipment is capable of producing panels complying with a specific standard may be limited.

For example, many roll-forming equipment manufacturers maintain Underwriters Laboratories (UL) Inc. certifications for compliance of metal roof panels fabricated using their equipment with UL 580, "Tests for Uplift Resistance of Roof Assemblies." Specific roll-forming machines purchased from these manufacturers bear UL certifications, which means the machines can produce metal roof panels that comply with UL's requirements for certification for a defined period, typically six months from the date on which the roll former was purchased. After the initial six-month period, a machine will require recertification.

For a roll-forming equipment owner to obtain recertification, he or she must apply in writing to UL, pay the fees associated with recertification and enter into an agreement for UL follow-up service. With follow-up service, a UL representative conducts periodic inspections to verify the equipment is capable of fabricating panels according to the original certification. The follow-up service facilitates an ongoing certification.

Additional information regarding the standards applicable to roll-forming equipment and the need to recertify the equipment should be available by contacting roll-forming equipment manufacturers.

Information about metal roof panels that comply with UL 580 is available from www.ul.com; click on "Online Certification Directory" in the Tools section at the bottom of the home page and enter "TJPV" in the UL Category Code field.