Most of the discussion about the green building movement has centered on the processes, materials and practices used when constructing new, more energy-efficient facilities. Within the commercial roofing industry, much of the attention has been aimed at the return on investment opportunities with photovoltaic and vegetative roofing options, and the debate about white or light-colored reflective roofing materials has focused primarily on TPO, white EPDM and PVC membranes. Insulation also plays a primary role in generating a building's energy savings.

Since gaining industry acceptance during the mid-1970s, millions of square feet of polymer-modified bitumen and built-up roof systems have been installed on commercial, industrial and institutional buildings throughout the U.S.; they, too, should be part of the conversation. Making traditional polymer-modified bitumen roof systems more energy efficient can be accomplished in a number of ways, including reroofing and re-cover options.

LEED® influence

There is no question the U.S. Green Building Council's LEED programs have positively influenced the expectations for buildings' energy performance. What you may find surprising is one of the fastest-growing LEED Rating Systems is LEED for Existing Buildings: Operations & Maintenance (EBOM).

According to a recent article posted on GreenBiz.com,® the number of LEED EBOM-registered projects in California has risen more than 300 percent during the past two years. With more green jobs and spending on the way, this number undoubtedly will continue to increase. As a result, existing buildings are being increasingly scrutinized for remedies to control rising energy costs. For many buildings, substantial savings can be achieved through relatively minor changes or upgrades to existing roof systems, including polymer-modified bitumen roof systems.

With the continuing need to meet local, state and national energy codes, roofing contractors are well-equipped to help building owners identify solutions that enable polymer-modified bitumen roof systems to meet such requirements.

Improving an existing roof system's energy efficiency can be accomplished by increasing the insulation's R-value or installing a highly reflective, cool roof surface or coating. These options are available in situations where an existing roof system is a traditional polymer-modified bitumen system; however, I will focus on the role a reflective polymer-modified bitumen cap sheet can play as a cool roof solution.

Cool roof specifications are included in numerous codes and programs, including California's Title 24 and the Environmental Protection Agency's ENERGY STAR® program, as well as standards and codes established by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Inc., LEED and Green Globes. In addition, many local municipalities have adopted similar cool roof requirements.

Among the more well-established and credible resources for cool roofing product information is the Cool Roof Rating Council, which publishes the initial and three-year solar reflectance and thermal emittance values for many products on its website, www.coolroofs.org. Another important rating is the Solar Reflectance Index (SRI). SRI values are available through an easy-to-use calculator such as the Department of Energy's Cool Roof Calculator, which was developed by Oak Ridge National Laboratory, Oak Ridge, Tenn.

For the past 10 years or more, the most common way to obtain a highly reflective roof surface was to apply a white or light-colored coating to a roofing material. This method has been effective with black EPDM, built-up and polymer-modified bitumen roof systems. During the past three years, roofing materials manufacturers have provided a more economical solution with pre-manufactured reflective built-up and polymer-modified bitumen cap sheets. These products provide an easier and usually lower-cost option to provide a reflective surface without having to apply an additional coating.

There are five types of highly reflective cap sheets currently used in North America:

- Cap sheets coated with acrylic coatings in factories

- Cap sheets with laminated films or painted foils

- Cap sheets with laminated aluminum foils

- Cap sheets with synthetic chips

- Cap sheets with reflective roofing granules

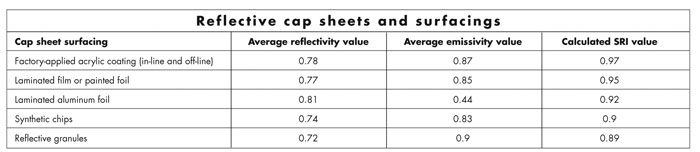

Typical reflective cap sheet surfacings for built-up and polymer-modified bitumen roof systems according to the September 2010 Cool Roof Rating Council's Rated Products Directory

The figure summarizes these cap sheets with an average of the reported values for reflectivity and emissivity. The SRI values were calculated using the average data to determine the relative range. The data indicates SRI values range from 0.89 to 0.97. SRI value is a key criterion to qualify for LEED's EBOM SS Credit 7.2 (Heat Island Reduction: Roof), which requires a minimum SRI of 0.78.

Which cap is right?

SRI and reflectivity values are important considerations when seeking to enhance a roof system's energy efficiency, but each cap sheet has other factors to keep in mind, which follow:

- Cap sheets with acrylic coatings. A variety of elastomeric acrylic coatings are available to provide asphaltic substrates with a reflective, protective seal. Although these types of cap sheets are designed to extend roof system life and lower energy costs, additional labor is required to install the coating. It also is important to monitor an acrylic coating's performance regularly to ensure proper adhesion. Acrylic coatings will need to be reapplied during a roof system's service life.

- Cap sheets with laminated plastic films or painted foils. There are a few reflective cap sheets made with laminated plastic films that either have a white plastic film on the surface or a proprietary acrylic surfacing applied during production to a polymer-modified bitumen roofing product. These reflective products have high SRI values and are said to resist contamination typically deposited on a roof. As with all laminated films to asphalt, when exposed to weather and temperature cycles, these products may wrinkle or delaminate because of the difference in expansion and contraction of the films from the main membrane structure. Also, these products need to be protected during installation and during a membrane's life to prevent the thin surfaces from being damaged by roof traffic.

- Cap sheets with laminated aluminum foils. Some polymer-modified bitumen sheets are made with an embossed aluminum foil to protect against ultraviolet radiation and enhance reflectivity. Although such products' average reflectivity values are high, their emissivity values generally are lower than other options. These foil-laminated products have the reflectivity and SRI values to meet LEED or Title 24 requirements but are not typically used in the field of a roof because they easily can be damaged from roof traffic. These products usually are used in wall flashing applications where they have performed with minimal issues.

- Cap sheets with synthetic chips. Synthetic chips, which are made with an acrylic binder and fillers, provide greater reflectivity than conventional reflective roofing granules. However, contractors have reported these products have high levels of granule loss and are easily damaged. They are new to the industry, and their long-term performance is yet to be determined.

- Cap sheets with reflective roofing granules. This is one of the newest forms of pre-manufactured, highly reflective cap sheets. The granules are applied during the manufacturing process, which eliminates the need (and cost) for field-applied coatings. Underwriters Laboratories Inc.- and FM Global-approved, these cap sheets resist foot traffic and hail and demonstrate good granule retention.

On the rooftop

One recent example of using traditional polymer-modified bitumen roof systems to improve energy efficiency involves the use of two different cap sheets installed atop a Chicago school. In 2009, Tyler Lane Construction awarded A-1 Roofing Co., Elk Grove Village, Ill., the reroofing contract for Stephen Mather High School, as well as the installation of a new roof system on the school's library addition.

The 8,000-square-foot library was built with the goal of qualifying for a LEED Silver rating. The new roof has 5/8-inch-thick primed roof board mechanically attached to a metal deck and a two-ply Type 4 fiberglass felt set in hot asphalt as a vapor retarder. Over the vapor retarder, two layers of 2 1/2-inch-thick polyisocyanurate insulation were installed in hot asphalt (the insulation has an R-value of 30).

Next, A-1 Roofing attached a layer of 1/2-inch-thick wood fiber insulation in hot asphalt and then set two plies of Type 6 felt in hot asphalt. For the top layer, A-1 Roofing installed a Firestone SBS FR UltraWhite™ cap sheet in hot asphalt. The cap sheet features reflective granules embedded into the sheet during manufacturing. (The LEED Silver rating is pending.)

For the building's 120,000-square-foot reroofing portion where a LEED rating was not desired, the existing SBS polymer-modified bitumen roof system was removed down to the gypsum deck. A new base sheet was mechanically attached to the deck followed by two plies of Type 4 felt and tapered polyisocyanurate insulation installed at a 1/4:12 slope with an average R-value of 20, all set in hot asphalt.

Continuing with hot asphalt attachment, A-1 Roofing then installed a 1/2-inch-thick wood fiberboard, two plies of Type 6 felt and topped the system with a standard Firestone SBS FR White cap sheet.

"This project is a great example of how traditional products like polymer-modified bitumen can provide green building benefits," says David Rabin, A-1 Roofing's vice president. "Compared with conventional granules, the bright white granules on the UltraWhite cap sheet are a noticeable improvement in reflectivity, which reduces the drain on the building's HVAC system. Plus, we know polymer-modified bitumen will withstand the test of time and the elements, and it won't need to be recoated in the future."

A viable option

With the range of reflective products and surfacing options available, roofing contractors are well-armed to help make polymer-modified bitumen roof systems a key consideration in the green building movement for every building type and budget.

Ruben G. Garcia is asphalt products marketing manager for Firestone Building Products Co. LLC, Indianapolis.