Editor's note: Following is the second in a two-part series addressing hail damage to roof systems. Part one appeared in the May issue, page 34, and focused on steep-slope roof systems.

Following hailstorms, roofing professionals, insurance professionals and building owners often automatically assume roof systems need to be repaired or replaced. However, though hail can inflict serious damage on roof systems, this is not always the case.

To identify hail damage on low-slope roof systems, you must understand basic properties of various low-slope roof system types and be able to recognize the effects of other natural perils, inherent manufacturing issues and typical weathering issues.

As I mentioned in part one, a roof system is not considered functionally damaged by hail unless the roof's weather resistance capabilities are diminished or the roof's expected service life is reduced. And whether a roof system is functionally damaged by hail depends on the hail size and hardness and roof system type and condition.

General rules

There are some general rules to consider when investigating a hail-damaged low-slope roof system.

First, the thicker the membrane, the greater the hail resistance. For bituminous and thermoplastic roof membranes, the more weathered the roofing material, the more brittle the membrane and, therefore, the less impact resistance it will have. The stiffer the underlying substrate, the more hail-resistant the roof membrane. Gravel surfacing affords substantial hail protection—more and larger aggregate surfacing typically means greater resistance.

Fractures caused by hailstone impacts typically start in membranes' undersides where tensile strains are greatest and propagate toward membranes' topsides. Base flashing usually is damaged by hail before other parts of a low-slope roof system because of its exposure and typically less solid underlying support.

When looking for hail damage on low-slope roof systems, remember:

- Over time, fracture edges become progressively more rounded and fracture surfaces more weathered; hail-caused damage does not disappear.

- The cutting and removing of samples from a roof membrane permits an inspector to examine the roof covering's underside where impact-caused fractures initiate. (Such destructive testing may not always be possible.)

- Roofing samples can be transported to a laboratory and further examined under magnification. Bitumen can be desaturated from roofing and reinforcements extracted; thermoplastic membranes can be backlit by high-intensity light and scrutinized visually; roofing materials can be X-rayed (in instances where protective surfacing is other than granules or gravel ballast) and fractures detected; and magnetic resonance imaging can be performed to determine the position of fractures within the material's thickness.

- Impacts can be made against roof assemblies with simulated hailstones and compared with areas of interest on roof systems.

- Infrared thermography and impedance meters can help identify whether water has migrated through hail-caused openings and into roof assemblies.

Damage thresholds

Hail must be a certain size and hardness to functionally damage low-slope roof systems. However, the size required varies depending on low-slope roof system type and condition.

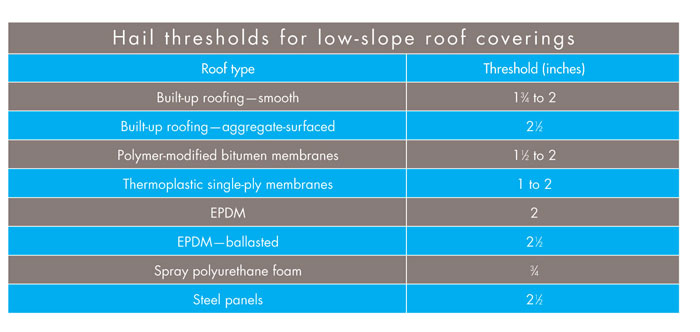

The smallest threshold sizes of hail that can damage various low-slope roof coverings

The figure lists the smallest size thresholds for common low-slope roof system types. The thresholds, which are the culmination of more than 45 years of laboratory testing with simulated hail and tens of thousands of field inspections, are provided given the following set of assumptions: hard hail, perpendicular impacts, average support, and roof systems in relatively good or midlife condition.

Built-up

A built-up roof (BUR) system is composed of a series of reinforcements bonded together with a waterproofing material such as asphalt, coal tar or polymer-modified bitumen. Hail of sufficient size, speed and hardness can puncture, tear or bruise a BUR membrane.

Hail-caused fractures always are visible on a membrane's underside (unless obscured by insulation remnants or adhesives). Although some fractures may not be obvious in roof surfaces, they can be detected by hand and feel like localized soft spots or bruises on an apple. The softness results from broken reinforcements in the membrane.

When a BUR system is smooth-surfaced (surface flooded with bitumen or coated with aluminum, polymer or emulsion), impact marks and resulting punctures and fractures are detectable when examined closely and tactilely. If a BUR system is aggregate-surfaced, you must first sweep (or blow) the loose surfacing aside. This will expose any nonweathered, black-colored bitumen where sizeable hail has dislodged and ejected the flood coat with surfacing from the impacted site.

A BUR system's expected service life can be shortened when protective surfacing is dislodged by hail. Examples include the flood coat bitumen or gravel embedded in the flood coat broken away or aluminum, polymer or emulsion coatings disrupted.

Polymer-modified bitumen

Polymer-modified bitumen membranes are composed of fiberglass and/or polyester reinforcement, and their top surfaces are protected by surfacing such as factory-embedded granules, factory-bonded foils or field-applied coatings.

Hailstones of sufficient size and hardness can puncture, tear or bruise a polymer-modified bitumen membrane where they strike and reduce the membrane's weatherproofing capability. A roof system's expected service life can be reduced when hail disrupts the membrane's protective surfacing and exposes its coating bitumen.

The best way to examine a polymer-modified bitumen membrane is to feel areas with sizeable impact marks by pushing against the membrane to discern localized soft spots, which indicate ruptures in the reinforcement. Fractures in polymer-modified bitumen membranes' top surfaces can be curvilinear or a series of fractures in a concentric pattern. Fractures in concentric patterns in membrane surfaces typically are accompanied by fractures in star-shaped patterns (multiple fractures radiating from common impact points) in membranes' undersides.

Areas without hail-caused punctures, tears or bruises where granules have been dislodged must be probed further to determine whether the exposed polymer-modified bitumen has additional underlying granules. In many instances, though some granules will have been dislodged and dark-colored bitumen exposed at the impact site, you will discover additional granules just below the exposed bitumen's surface. These granules protect the polymer-modified bitumen and reinforcement below; therefore, there is no loss of service life and no functional damage.

Single-ply membranes

Common thermoplastic membranes such as PVC and TPO typically incorporate reinforcement in woven forms known as scrims. The most prevalent thermoset roof membrane is EPDM, which is produced as reinforced (with polyester scrims) and nonreinforced membranes. Hail damage to thermoplastic membranes includes fractures or tears in the material body or reinforcement.

Roof areas most sensitive to damage typically are at underlying stress plates in lap seams of mechanically attached systems or those used for fastening underlying insulation boards.

Hailstone strikes against membranes at stress plate edges are known as "anvil strikes" and result in crescent-shaped fractures 1/16 of an inch to 1 inch long. Fractures in thermoplastic membranes (away from stress plates) over insulation or deck materials can be curvilinear, star-shaped or a series of fractures in a concentric pattern.

Larger fractures in thermoplastic membranes are plainly visible. Smaller fractures require closer inspection and hand manipulation to identify. Pushing on a membrane will identify dents in underlying insulation for further scrutiny. Tugging at the membrane at areas in question will open miniscule fractures.

When looking for hail-caused damage in thermoplastic roof membranes, keep in mind:

- Fractures in membranes generated by hailstone impacts are immediate and detectable by a knowledgeable inspector.

- Hail-caused fractures are visible immediately in all membranes' undersides.

- Fractures caused by hail are visible immediately when backlit by high-intensity light.

- Good lighting is important for identifying smaller fractures in thermoplastic membranes.

- Water, snow and ice on a membrane may obscure fractures completely.

- Fractures in some thermoplastics, especially PVC, may not be readily visible in membranes' top surfaces until the membrane has "relaxed."

- Fractures in brittle nonreinforced PVC membranes are star-shaped and tend to propagate when the membrane is taut.

- EPDM is an elastic material and does not accumulate stress or fatigue when struck by multiple hailstones.

- Generally, thermoplastic roof membranes are more sensitive to impact-caused damage in colder temperatures.

- Insulation below membranes can be dented or fractured, which may constitute functional damage.

SPF

Spray polyurethane foam (SPF) roof systems are composed of multiple lifts of polyurethane foam finished with an elastomeric coating. Depending on hail's attributes, resulting damage can range from fractures in the elastomeric coating to punctures in coating accompanied by crushing or fracturing of the polyurethane foam.

Closely inspect SPF roof systems for hail-caused damage, and feel any areas of concern by hand. Recommendations for repairs are available from the Spray Polyurethane Foam Alliance based on the extent and frequency of the damage.

Metal

Inspectors will encounter many types of metal roofing materials. Metal can weather naturally or be protected by coatings. Panels are manufactured in a variety of widths and thicknesses with various types of seam configurations and applied with exposed or concealed fasteners.

When investigating hail damage, closely examine metal roofing panels. These can be damaged when hailstone parameters are sufficient to rupture the metal, disengage lap elements or disrupt protective coatings. Ruptures in panels and disengaged lap elements are obvious.

Micrographs have verified that thinning of metal—even within deep dents—is insignificant. Analysis of hail-caused dents with a scanning electron microscope and analysis of products accumulated within dents using dispersive X-ray spectroscopy have demonstrated that factory-applied coatings—galvanized, Galvalume® and fluoropolymers—are not damaged by hailstone impacts even when the metal is dented. However, field-applied paints may be vulnerable to hailstone impacts.

Careful conclusions

Hail damage is fairly frequent and can wreak havoc on roof systems. But in the event of a hailstorm, try not to make any hasty conclusions about the need for repairs or replacement. Take time to carefully identify hail damage and whether it is considered functional damage before deciding whether to perform localized repairs of damaged roofing materials or replace the entire roof system.

Scott J. Morrison, P.E., is principal engineer for Haag Engineering Co., Irving, Texas.