Golf is a game people love to hate. Players curse their closest relatives, pray to the gods and foam at the mouth until they get the perfect drive or putt that makes the world make sense again. But sometimes, the craziest antics occur before a golfer even plays a round.

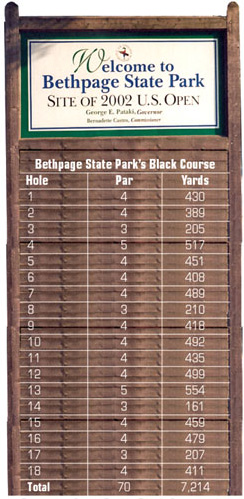

Consider Farmingdale, N.Y.-based Bethpage State Park, a public golf course touted to be "the people's course." Bethpage State Park has five courses—black, blue, green, red and yellow—and getting a tee time on any course, especially the Black Course, rarely can be done by telephone. Therefore, people arrive early to play the par-70, 7,214-yard (6565-m) Black Course, which bears a warning sign at its entrance stating, "The Black Course is an extremely difficult course, which we recommend only for highly skilled golfers."

Photo courtesy of Long Island Roofing and Repairs Service Corp., Bellmore, N.Y.

Bethpage State Park, a public golf course in Farmingdale, N.Y.

Golfers—mostly men—arrive in Bethpage State Park's circular parking lot at midnight or later. They park their cars in numbered spots and wait for a park ranger to arrive with a list of open tee times for the following day (Bethpage State Park reserves a certain number of walk-up slots per hour). If there are open tee times, the park ranger gives raffle tickets representing reservations for specific tee times to each person in each car. Many golfers sleep—or drink and talk—in the parking lot all night until their tee times.

Although most people would shake their heads at this and wonder, "What possibly could possess someone to camp out to golf?", others seem to know why. The United States Golf Association (USGA) allowed the world to witness the excitement behind the Black Course in 1996 when it scheduled the 2002 U.S. Open Championship there June 13-16.

New York and USGA officials spent six years preparing the dilapidated but beloved course for the championship. In addition, Bethpage State Park's facilities were improved. Long Island Roofing and Repairs Service Corp., Bellmore, N.Y., was asked to tear off and install roof systems on two Park's Department storage facilities between the second and 13th greens.

Photo courtesy of Long Island Roofing and Repairs Service Corp., Bellmore, N.Y.

Roof systems on two Park's Department storage facilities (both photos) were torn off and replaced at Bethpage State Park, Farmingdale, N.Y. Roofing work was done in preparation for the 2002 U.S. Open.

The project consisted of 30,000 square feet (2700 m²) of steep-slope roofing work and 700 square feet (63 m²) of low-slope roofing work. The low-slope roofing work only was featured on one building. Roofing workers had to eliminate a cricket in one building's roof system; install fascia, gutters and leaders that were not included in original roof systems; and replace flashings.

Creating the courses

Bethpage State Park's story begins with Robert Moses, renowned New York builder and president of the Long Island State Park Commission for 38 years. In 1931, Moses wanted to take over railroad tycoon Benjamin Yoakum's estate that included a private golf course, Lenox Hills Country Club. The Great Depression left the state with no funds to purchase land, so local towns purchased a one-year option for the land. On April 23, 1932, the course was named Bethpage Golf Club and opened to public play for $2 per day. On Aug. 26, 1933, former New York Gov. Herbert Lehman signed legislation authorizing $100,000 in cash and $900,000 in bonds to be transferred to Yoakum's heirs for the Bethpage Golf Club title.

Moses wanted to further expand the course and did so despite the Great Depression. Moses issued revenue bonds to purchase more land and used the Depression-era Works Relief Project Act to get more than 1,800 workers to build three more courses—black, blue and red—in addition to the original Green Course. Work began in the summer of 1933.

According to most sources, Albert Warren Tillinghast was asked to redesign the Green Course and create plans for the Black, Blue and Red courses. But Golf Digest magazine and Joe Burbeck, who lived on the Black Course as a child, tell a different story. Reportedly, Joseph H. Burbeck, Joe's father and Bethpage State Park's former superintendent, designed the courses. Based on Bethpage State Park documents showing Tillinghast was hired as a consultant after course designs began and fired before the Black Course opened, Golf Digest ran an editor's note in June stating, "In future references, Golf Digest will list Joseph H. Burbeck as the architect and A.W. Tillinghast as a consultant." (Visit Golf Digest's Web site, www.golfdigest.com, for more information.)

Despite the controversy, the Blue and Red courses opened in 1935 and the Black Course opened July 2, 1936; the Yellow Course didn't open until 1958. Since the 1930s, about 14 million rounds of golf have been played on all the courses.

But it is the Black Course that draws the most attention. More than 30,000 rounds are played on the course per year. One round costs $31 on weekdays and $39 on weekends, and the course profits about $1 million per year. The course has become a mecca for golfers because of its natural surroundings, unique design and difficult play. Most of the course is surrounded by shin-high heather, and the course features 8-foot (2-m) bunkers and flat greens.

Nick Faldo, who finished the 2002 Open in fifth place, said: "Well, they call them flat, but I haven't had a straight putt yet. [The greens] are very slippery, and they have such a good surface on them."

Bethpage State Park's Black Course, the site of the 2002 U.S. Open, is the longest course played for an Open.

The Black Course became part of U.S. Open history. It is the longest course and first public course played for a U.S. Open.

Damaged roof systems

When preparing facilities to make history, Long Island Roofing and Repairs Service discovered that buildings still had original steep- and low-slope roof systems. Original steep-slope roof systems consisted of wood shakes on top of wood nailers. The shakes were covered by two layers of asphalt shingles. The roof systems did not have fascias, gutters and leaders, which affected the buildings. For example, wood shake siding was damaged from rain that fell off the roof systems and was blown back into the buildings. The low-slope roof area also was in poor condition.

"The low-slope roof deck was deteriorated with numerous layers of built-up roofing [material] on top of it," says Steve Coppolo, president of Long Island Roofing and Repairs Service.

During steep-slope tear-off, asphalt shingles and wood shakes were removed. To meet historic preservation guidelines, wood nailers were not removed. The original low-slope roof assembly—including the deck and rafters—was removed.

Working together

The project's area was about 5 acres (2 hectares), and Long Island Roofing and Repairs Service's equipment and materials had to be stored in a specific location within the area so roofing work didn't interfere with the Park's Department's equipment and work. The Park's Department had about 100 employees working during the roofing project to maintain the course and prepare it for the Open. Coppolo's crew, therefore, had to coordinate its work with the Park's Department's work.

For example, because the Park's Department's equipment could have been damaged by roofing work, its equipment was stored in the building not being worked on during the roofing project's tear-off phase.

Coppolo says, "Bethpage State Park's superintendent, who is responsible for how great the course looked for the Open, helped plan and assisted his crews and our crew so there would be no conflicts throughout the project."

To maintain safety, roofing work areas were roped off each day after Park's Department employees removed their needed equipment. At the end of each day, roofing areas were cleaned and roofing materials were stored. To ensure damage didn't occur to Park's Department equipment or the Black Course, roofing workers cleaned the areas with magnetic brooms three times per night to ensure nails were not present.

Installation

Long Island Roofing and Repairs Service's crew size varied from six workers to 12 workers depending on how much work was slated each day.

Work began on the steep-slope roof systems by installing 1,200 feet (360 m) of 1 1/4-inch (32-mm) primed fascia on all gutter lines and gables. A 5/8-inch- (16-mm-) thick Georgia-Pacific CDX roof deck then was installed, and a 0.032-inch (0.8-mm) aluminum drip edge was placed over the wood deck's edges. Roofing workers installed GAF Weather Watch® Leak Barrier at the gutter lines and in the valleys.

Photo courtesy of Long Island Roofing and Repairs Service Corp., Bellmore, N.Y.

Long Island Roofing and Repairs Service installed GAF Timberline shingles, as well as fascia, gutters and leaders, which were not included in the original roof systems.

Next, 30-pound (14-kg) tar paper was laid in place. Finally, GAF Timberline® 30-year shingles were fastened with 1 1/2-inch (38-mm) nails. Because the roof has 600 feet (180 m) of ridges, it was vented with GAF Cobra® Ridge Vent. GAF Timbertex® ridge caps completed the roof system's new look.

For the low-slope roof, roofing workers began by installing new rafters and a new deck. Structodek 3/8-inch- (10-mm-) thick recovery board was fastened to the deck using Olympic screws and plates. After a new aluminum trim was installed, U.S. Intec Flex M modified bitumen roll roofing set in Karnak #81 adhesive was troweled down. To create accurate dimensions, new gutter and leader systems were fabricated on-site.

Equipment

All work was finished in 10 days. Coppolo believes the project was completed ahead of schedule because of time-saving tools, such as cordless framing hammers, used to install the steep-slope decks and fascia.

Coppolo adds, "The hammers helped the crews gain a lot of time because of the convenience of not having to address problems that can occur when working with compressors and hoses from air guns."

However, compressors and air guns were used to install the new shingles.

Equipment also played an important role when delivering materials. The company rented an all-terrain four-wheel drive forklift, which telescopes 24 feet (7 m), to get materials onto rooftops.

Coppolo says: "Using the forklift made the project much safer and more efficient. All materials were picked up from where they were stored and sent up to the middle of the roofs so roofing workers could have access to materials at the rooftops."

Keys to success

When Rees Jones, a golf course designer, began renovating the Black Course, he said the course "had trees growing in bunkers; hardpan for rough; crabgrass on the greens; and fairways pockmarked with divots."

Similar to Jones and others involved in the renovation, Long Island Roofing and Repairs Service faced a meticulous project. But organization and preparation made the job less daunting.

"Preparing for the project with regard to ordering materials, coordinating with suppliers and renting equipment were the key issues that helped the project run efficiently, on time and under budget," Coppolo states.

Tiger Woods won the Open 3 under par; he was the only player to finish under par. Woods said, "Playing the championship here, on a public facility such as this, it's incredible."

Because of the success in June, players, spectators and New York officials hope the Open will return to Bethpage State Park. The earliest the course could make an encore performance is 2010. Until then, those involved in the 2002 Open still are reveling in their work and celebrating the Black Course's beauty and intrigue.

Coppolo notes, "It was a great feeling to watch the U.S. Open on television … and know people were getting a glimpse of our work."

Kate Gawlik is associate editor of Professional Roofing magazine.