Professional Roofing is pleased to offer you a pullout section detailing common fasteners used in roof systems. The following information has been excerpted from The NRCA Roofing and Waterproofing Manual, Fifth Edition.

A variety of mechanical fastening devices can be used for attaching base sheets, rigid insulation, bituminous and single-ply membranes, and sheet metal to various substrates.

It is NRCA's position that no mechanical fasteners should be installed into or through wet roof insulation. Exposure of carbon or stainless-steel fasteners to wet conditions within a roof assembly will result in accelerated deterioration of fasteners and the roof deck and ultimate release of fasteners from the roof assembly.

It is a specifier's responsibility to determine the acceptability of a fastener type for a roof system (including sheet metal) and roof deck. The following descriptions of generic fasteners and their generally recommended use in various roof decks and substrates are provided for information only based on the recommendations made by roof system and fastener suppliers.

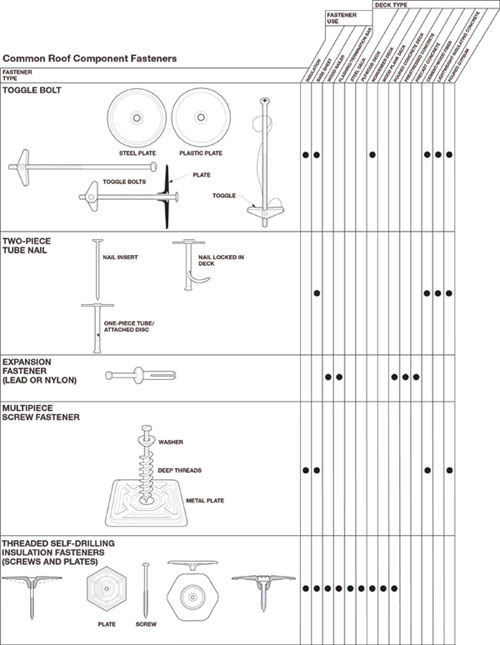

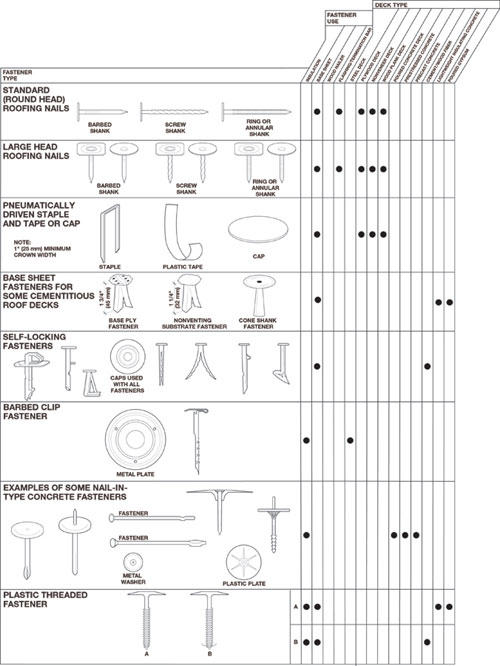

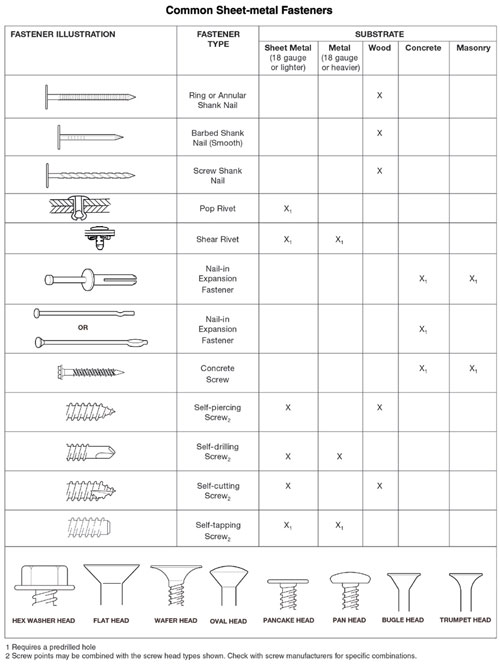

The first chart, Common Roof Component Fasteners, provides illustrations of various roof component fasteners, generic fastener types, fastener uses, and appropriate decks or substrate types. The second chart, Common Sheet-metal Fasteners, provides illustrations of common sheet-metal fasteners, generic fastener types, appropriate substrate types and screw head shapes.

Mechanical fasteners typically are classified by material composition, surfacing/coating, generic fastener type and size. Additional classification parameters may be required depending on specific fastener parameters.

Nails and screws typically are classified by material composition, surfacing/coating, type of shank, type of point, head shape and size.