Choosing the best means for extending roof system service life involves a number of factors. Coatings are one option and can be cost-effective, but their varying performances can create limitations. The reasons a particular coating works in one situation but not another often are complex and difficult to determine. Some limitations of coatings are related to climatic variables.

In the U.S. and Canada, two primary factors seem to dominate regional roofing practices: total annual precipitation and freeze-thaw cycles associated with cold climates. Secondary factors include Hail Belt conditions east of the Rockies, afternoon rain in the Gulf states and Midwest, Florida's tropical characteristics, intense summer temperatures in the Southwest and high winds.

Moisture

Coatings, particularly those that are water-based, can be affected by moisture in at least two critical ways: They can be worn away by rain or heavy dew or can experience diminished adhesion to damp surfaces. In the eastern half of the U.S., these risks are reduced by using silicone coatings and bituminous-based coatings. ASTM D16, Type V urethanes and new generation polyureas are high-performance and environmentally compliant options when rain is typical or a tough, traffic-bearing membrane is needed.

Water-based products are restricted to a narrow application season, especially in northern climates. However, acrylic latex coatings, such as those meeting ASTM D6083-05, "Standard Specification for Liquid Applied Acrylic Coating Used in Roofing," are commonly used because of reasonable cost and good long-term performance. Coatings meeting ASTM D6083 generally have more resin and can provide substantial insurance against the effects of ponding water.

In contrast, products with high filler content generally have higher permeances and lower wet adhesion than those meeting ASTM D6083; these are not good choices for wet climates.

In the West, sunny and generally drier conditions lend to the domination of acrylic coatings. In this environment, excellent ultraviolet (UV) protection combined with affordability and user-friendly application make acrylic coatings an obvious choice for new or retrofit projects.

A discussion about U.S. precipitation is not complete without mention of snow and ice. They create a special challenge for roofing contractors because of the possibility of associated ponded water. Accumulation of snow and ice may persist for weeks or months, often piling against vertical surfaces, such as mechanical equipment and parapets. There is no guarantee normal drainage and slope will protect a coating in such a situation.

Although water- and solvent-based coatings may exhibit similar adhesions in dry or short-term wet conditions, after a few days of immersion, most water-based products may lose up to half of their initial adhesion.

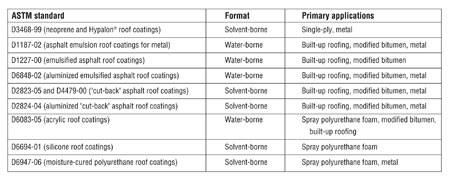

ASTM International standards for roof coatings

ASTM D6083 prescribes an adhesion test that involves soaking a relatively short-cured coating for one week. This test provides a good screening of candidate coatings for roofing applications in climates prone to snow and ice. If a cured membrane sustains its properties through the first few rains or a heavy snowfall, it is unlikely to fail for an extended time period. In general, properly applied water-based coatings may last as long or longer than many solvent-based options.

Cold temperatures

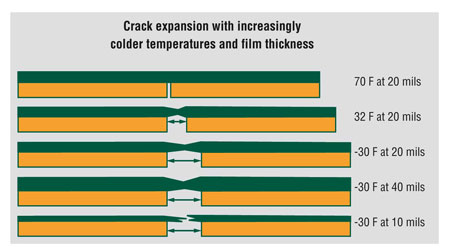

Because much of the U.S. experiences low temperatures at some point during the year, there is a need for coatings with low-temperature flexibility. ASTM standards for silicone, acrylic and polyurethane coatings require that coatings be flexible enough to withstand typical building movement anywhere in the U.S. at temperatures as low as -30 F. Coatings used in roofing also must possess and maintain good crack-bridging capability in cold weather.

Furthermore, because the ability to bridge cracks is affected by film thickness, strength, elongation and flexibility, it is crucial to define a minimum acceptable value. Roof systems in northern climates perform better with thicker films of coatings generally being warranted at flashings, penetrations, protrusions, vertical and horizontal transitions, and other critical roof areas. The increased water resistances of films in the 20- to 40-mil-thick range provide insurance against rain, snow and low temperatures.

Hail

Hail resistance requires a flexible yet tough material, typically characteristic of a polyurethane coating. However, some acrylic and silicone coatings have passed severe hail-resistance tests as referenced in Underwriters Laboratories Inc. and FM Approvals listings.

If hail is a significant risk in your region, take special note of testing performed on unaged and aged coatings. Coatings often harden under normal weathering as they age. Real-world conditions demand that a roof system withstand many years of service with a margin of safety to buffer the variability of the substrate, coating and weather.

Biological attack

In Florida, as with much of the Gulf Coast and other periodically damp, warm regions across the U.S., algae and mildew can create serious problems, resulting in damage if left unchecked. Silicone is probably the most effective coating for resisting biological growth because it contributes no food source and resists microbial attachment. Coatings made from urethanes, asphaltics and acrylics can support growth and must be specially formulated for warm, damp environments.

A roof coating can fail when a layer of biological material bonds to the coating and then shrinks in warmer weather. The strong adhesion of the living layer combined with the powerful shrinkage can actually pull the coating off the underlying membrane. I refer to this as "potato chipping." However, this scenario can be prevented.

One factor to keep in mind is color. White is great for reflecting the sun's rays and keeping a building cool, but it also stays wet longer and allows more mildew and algae to grow; even a light gray will support less growth.

Additionally, some manufacturers make acrylics with slicker surfaces and extra biocide to better resist dirt and moisture accumulation conducive to biological growth.

Bituminous-based coatings, on the other hand, control growth by getting hotter and staying drier in the summer.

Many ASTM standards include algae and mildew testing, and that assurance is adequate for most of the U.S. against biological damage. However, even if a product passes ASTM G21-96, "Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi," or ASTM G29-96, "Standard Practice for Determining Algal Resistance of Plastic Films," you still need to make sure it has extra biocide if it is a water-based product for use in tropical climates. Water-based products often include minerals that organisms eat, as well as water-soluble thickeners and emulsifiers that are food for algae and mildew. In most cases, water-based coatings will allow some growth, but the key is making sure the organisms don't grow into the coating.

It is important to note a coating that initially meets ASTM requirements may eventually succumb to growth as biocide is depleted.

High temperatures

Sun exposure is another factor to consider when selecting a coating. When combined with cyclic temperature swings, periodic moisture, wind and other forces of nature, all roofing materials are subjected to measurable erosion over time.

Surfaces with high reflectivities and emissivities are likely to resist the elements longest. Traditional built-up, modified bitumen and many single-ply roof systems can benefit from the protection of UV-resistant coatings, provided they are designed to adhere properly and resist bleed.

How temperature affects a coating's thickness and susceptibility to cracking

In the Southwest, you can use a coating with the confidence it will not rain during application and the coating may never see ponding water. For these reasons, this is the market most dominated by white acrylic coatings. In the Southwest, low-cost materials, such as acrylics (even those that do not meet ASTM D6083), work well. ASTM D6083 requires excellent low-temperature performance but has a low UV-resistance requirement, so it isn't a reliable guide for the Southwest. Coatings with higher tensile strengths from firmer resins sometimes can perform better even though they may not meet ASTM D6083 requirements. One example is coating over asphalt.

In the Southwest, asphalt materials can become soft or fluid even when protected with a white coating. In these conditions, the asphalt bleeds readily into the coating and causes the coating to age more quickly. A slightly less-flexible coating (flexible to about 0 F instead of the -30 F required by ASTM D6083) can work better because the firmer resin blocks asphalt bleeding better and may resist UV rays better. Because of high temperatures in the desert, a white coating is always a good idea, and if you're using an acrylic coating over asphaltic substrates, a light color is a requirement for long-term performance.

Solvent-based coatings also can suffer from the ravages of the sun, UV rays and entrapped solvent. If a coating is applied too heavily or thinned with a solvent, such as xylene (which, when acted on by UV rays, can attack the coating resin while it's curing), excessive yellowing and premature enbrittlement may result. In the Southwest, the sun needs to be considered because it accelerates every reaction that contributes to the aging of these materials.

Regulations

Stricter volatile organic compound regulations are expected to be enacted soon in the Great Lakes region by the Lake Michigan Air Directors Consortium and in Canada by Environment Canada, Gatineau, Quebec, which certainly will affect urban areas. This will lead to an inevitable increase in reliance on water-based technology, such as water-based coatings.

Other factors that are driving the use of coatings to maintain roof systems include the increasing cost of landfilling (tilting the balance away from tear-off and replacement) and energy credits and legislation aimed at reducing air-conditioning costs and the urban heat island effect. Health and environmental concerns and their associated liabilities increasingly are influencing contractors' choice of roofing products, as well.

Understanding is key

Environmental stresses on coatings naturally vary between regions. If you choose to use coatings, understanding how to match weather conditions to the characteristics of various available coatings can lead to better roof system performance and building investment.

Steve Heinje is vice president of research for United Coatings, Spokane Valley, Wash., and co-chairman of the Roof Coatings Manufacturers Association's White Coatings Council.