The North American roofing community has long recognized the benefits of including a cover board to increase a roof assembly's durability. In the past, the main purpose of cover boards was to protect against weather elements and minimal foot traffic. As a result, cover boards were evaluated for their material properties based on standards that were developed for individual board types.

Rooftops now are used as platforms for add-ons, such as photovoltaic or vegetative roof systems, which result in increased foot traffic, loads and stresses on roof systems. In addition to the increased physical burdens, there are more frequent extreme weather events, including hailstorms and heavy winds, that can result in debris and other items contacting roof systems.

The roofing industry has responded to this need by manufacturing a wide variety of boards made from asphalt, gypsum, cement, wood fiber, insulation and recycled products. These boards are placed above the insulation substrate to provide additional protection for roof systems. However, there continues to be damage observed to substrates. This leads to two fundamental questions: What is a cover board? And what should a cover board be contributing to a roof assembly?

What they do

A cover board is a rigid roof material in a compact roof assembly that enhances resiliency and durability. It is installed below the membrane and above the insulation to minimize the deterioration of other materials during a roof system's service life. To achieve the goal of providing protection and minimizing deterioration, cover boards must meet certain evaluation criteria.

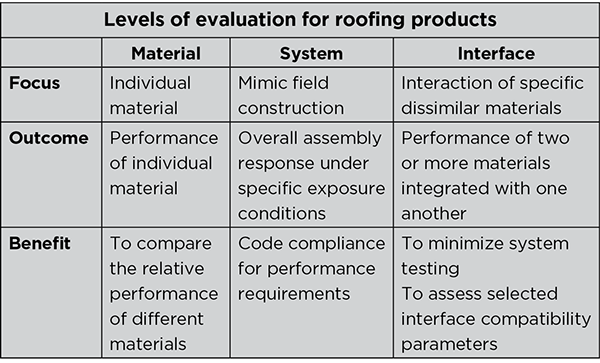

There are several levels of evaluation that can be considered for cover boards, including material, system and interface. The figure summarizes the three evaluation levels and resulting outcomes and benefits. Material evaluation is useful to obtain the properties of an individual material and can be used to compare the performance of different products. Properties, such as flexural strength and water absorption, can be assessed at the individual material level. However, in roofing, the materials, including the cover board, are integrated with one another, which results in interactions. Material testing alone does not capture the interactive element.

Levels of evaluation for roofing products

System evaluations, which are performed under specific set laboratory conditions, assess the overall assembly response and are essential to demonstrating code compliance. However, a system test will not isolate a cover board's protective characteristics. A system test focuses on the weakest link concept and failure mode and may not directly provide information about cover board performance. Furthermore, system evaluations can be tedious, costly and time-consuming because of the large number of variables that can be tested.

Interface evaluation (IE), which is the intermediate testing between material and system, is essential to assess the interaction of two or more dissimilar roofing materials. Properties, such as peel resistance, which is a localized characteristic among two materials, must be evaluated at its corresponding interface. Assessing the required cover board properties as IE allows for evaluating a cover board with the materials it is intended to protect. The cover board properties that require IE include peel resistance, cover board pull-through, resistance to repetitive loading and dynamic puncture resistance. These properties are essential for determining the protective characteristics of the various cover boards.

Peel resistance

Only IE can quantify the peel resistance of bonded or adhered materials in the face of shear forces. Existing system tests, which include ANSI/FM 4474, "American National Standard for Evaluating the Simulated Wind Uplift Resistance of Roof Assemblies Using Static Positive and/or Negative Differential Pressures," and CSA A123.21, "Standard Test Method for the Dynamic Wind Uplift Resistance of Membrane Roofing Systems," simulate uplift forces as opposed to shear forces.

IE complements system testing by determining the peel strength of a membrane and cover board and that of insulation and a cover board integrated together. Photo 1 depicts a membrane peel failure from a wood fiber board. A peel test for the cover board interfaces will establish the resistance requirement for ensuring cover boards are fulfilling their intended purpose.

Cover board pull-through

Photo 2 demonstrates a roof in the aftermath of a high-wind event. The weakest link in the system was determined to be the interface between the cover board and fastener plate. The cover board resistance was not sufficient to withstand pull-through, resulting in roof system failure. IE of the cover board and fastener plate will establish their interaction and determine the resistance required. In addition, several parameter evaluations can be performed economically through IE, such as variations in plate design and dimensions, to identify the optimum design combination of cover boards and fastener plates.

Resistance to repetitive loading

An example of rooftop repetitive loading is the vibrations of a photovoltaic panel and/or ballast tray, which in current practice are installed directly on a roof surface. Photo 3 shows the damage that can occur to insulation from repetitive loading when no protection is provided. When ballast weight is small (for example, 10 pounds), the resulting damage includes the compression and indentation on the insulation surface below the membrane. For heavier ballast or severe vibrations, the insulation facer can be punctured in addition to the compression of the insulation, which is not captured in material compressive strength evaluation. IE will help determine the required strength of the cover board to fulfill its protective function. Currently, there are no standard test methods to capture this behavior.

Dynamic puncture resistance

Evaluating dynamic puncture resistance is essential to simulate a sudden impact, such as the dropping of a hammer or other tool during a roof system repair or damage from a severe hail event. Current dynamic impact testing is for individual materials, such as membranes. However, the puncture of a membrane can be minimized by the substrate below. Cover boards absorb the impact energy and protect the membrane and insulation. Therefore, for the interaction of the membrane and insulation with the cover board under dynamic impact, IE is needed to establish the resistance required.

Photo 4 shows the damage to the membrane and insulation that was observed in the aftermath of a hail event for a system without a cover board. A thumb-sized depression was produced on the membrane, and a depression of more than 2 inches in diameter was observed on the top of the insulation board. Photo 4 also depicts schematically the benefit a cover board provides for protecting adjacent substrates.

The benefits of IE

To ensure cover boards are protecting a roof assembly, they must be evaluated with the materials they are intended to protect. This concept gave rise to the formulation of interface testing, defined as the intermediate testing between material and system testing that includes two or more dissimilar materials. As rooftops transition from having minimal burdens and foot traffic to increased foot traffic, overburdens and extreme climatic events, the cover boards of the future have a bigger role to fulfill. They will require more extensive, focused evaluation, and IE will be required to ensure cover boards fulfill the dual function of minimizing the deterioration of other materials and providing resiliency to roof assemblies.

Bas Baskaran is a group leader at the National Research Council of Canada, Ottawa, and Dominique Lefebvre is a research officer at the National Research Council of Canada.