For more than a decade, asphalt shingle manufacturers and the Asphalt Roofing Manufacturers Association (ARMA) have been developing a new methodology for determining the wind resistances of asphalt shingles. Development of this new methodology is nearing completion, and some asphalt shingle manufacturers are beginning to implement it.

I will provide an overview of the existing method for determining and reporting asphalt shingles' wind resistances, describe the new methodology and how it's used, and point out the importance of proper asphalt shingle selection and application when using the new methodology.

UL 997/ASTM D3161

For more than 30 years, wind resistances of asphalt shingles have been determined and reported based primarily on one of two largely similar test methods: UL 997, "Standard for Wind Resistance of Prepared Roof Covering Materials," and ASTM D3161, "Standard Test Method for Wind-Resistance of Asphalt Shingles (Fan-Induced Method)." In these test methods, a fan-induced wind is directed toward a test panel measuring 50 inches (1.3 m) wide and 66 inches (1.7 m) long; the panel consists of the asphalt shingles being evaluated installed according to the manufacturer's instructions.

The test panel is exposed to the fan-induced wind of a designated velocity for a minimum of two hours. A test panel fails the test when, at any time during the test's duration, a shingle's sealing feature (self-seal strip) fails to restrain one or more full shingle tabs or a locking ear or tab on an interlocking shingle tears loose or disengages from its locking position.

Any test panel that restrains full shingle tabs from lifting or locking ears from tearing loose or disengaging during the test duration is considered to have passed the test.

When these tests initially were developed, the designated fan velocity used was 60 mph (27 m/sec). This value was selected because it was representative of winds in the Beaufort Scale No. 10 range (55 mph to 63 mph [25 m/sec to 28 m/sec]).

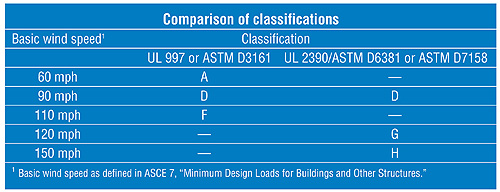

Figure 1: A comparison of wind-speed classifications

Following hurricanes that struck the southeast U.S. during the late 1980s and early 1990s and the relatively poor performance of asphalt shingles during these wind events, building code officials and the insurance industry called for improved wind resistance of asphalt shingle roof systems. To quantify the wind resistance of asphalt shingles at higher wind velocities, UL 997 and ASTM D3161 were revised to allow for testing at 90-mph (40-m/sec) and 110-mph (49-m/sec) velocities. As a result of this revision, asphalt shingles that pass the test at 60 mph (27 m/sec) are designated as "Class A"; those that pass at 90 mph (40 m/sec) are "Class D"; and those that pass at 110 mph (49 m/sec) are "Class F."

Asphalt shingles that are tested and classified by Underwriters Laboratories (UL) Inc. according to UL 997 or ASTM D3161 are listed in UL Category Code TFWZ, Prepared Roof Covering Products, UL's Roofing Materials Directory and the certifications section of UL's Web site.

Recently, UL 997 and ASTM D3161 have come under increased scrutiny and been criticized by some parties, including some asphalt shingle manufacturers. The critics say the tests' results do not necessarily correlate with actual performance in the field, particularly during high-wind events. Also, the maximum practical test velocity for these test methods is limited to 110 mph (49 m/sec).

Currently, building code officials and the insurance industry are calling for asphalt shingle wind resistances at higher velocities—up to 150 mph (67 m/sec) in some regions of the U.S.

Clearly, an improved method for determining the wind resistances of asphalt shingles is needed.

New methodology

A new methodology for determining the wind loads on and resistances of sealed asphalt strip shingles has been developed by Jon Peterka, principal of Cermak, Peterka, Petersen Inc., Fort Collins, Colo., a nationally recognized wind engineering firm, under a long-term research contract with ARMA.

One of the fundamental findings of Peterka's research incorporated into the new methodology is that unlike membrane roof systems, asphalt shingles are relatively air-permeable roof coverings.

When high winds reach a continuous membrane roof system, a large pressure differential occurs between the top and bottom of the membrane covering. In these instances, the membrane is serving as an airtight barrier that allows for the pressure differential.

Because shingles do not form an airtight seal, the pressure differential between the top and bottom surfaces of an asphalt shingle is somewhat less during similar high winds. As a result, the actual wind pressures acting on asphalt shingles are less than the pressures that would act on a membrane roof system during comparable winds.

A similar concept also applies to tile roof systems and has been the basis of determining some tiles' wind resistances since the mid-1990s.

Another fundamental concept in the methodology is that asphalt shingles' self-seal strips are the controlling mechanism in preventing shingle tab uplift and, subsequently, resisting wind blow-off of asphalt shingles. The self-seal strips' bond strength is a more important controlling factor in determining asphalt shingles' wind resistances than the shingles' attachment to a roof deck. In fact, once a shingle's self-seal strips have sealed, the asphalt shingle's attachment to the deck has little or no effect on the shingle's overall wind resistance.

UL 2390

With the new asphalt shingle methodology, the theoretical design uplift load acting on an asphalt shingle's self-seal strips is determined using UL 2390, "Test Method for Wind Resistant Asphalt Shingles with Sealed Tabs."

In this test method, a test apparatus and test deck largely similar to those used in UL 997 and ASTM D3161 are used. Pressure taps are mounted on an individual shingle tab specimen on the test deck, and readings from these pressure taps are taken when the specimen is subjected to a 35-mph (16-m/sec) air-flow velocity that is directed perpendicular to and across the test deck.

Wind-uplift pressure coefficients (DCp) are determined by measuring the pressures above and below a shingle's surface at the windward and leeward sides of the sealant strip while taking into consideration the shingle's rigidity (EI). The value for a shingle's rigidity also is determined by testing. As an alternative, a conservative value (2.5 lbf-in² [7.2 kN-mm²]) has been determined as being applicable to asphalt shingles complying with ASTM D225, "Standard Specification for Asphalt Shingles (Organic Felt) Surfaced With Mineral Granules," or ASTM D3462, "Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules."

The theoretical design uplift load acting on the sealant then is calculated according to provisions described in the standard based on the basic wind speeds prescribed in ASCE 7, "Minimum Design Loads for Buildings and Other Structures."

The values derived from UL 2390 are specific to the individual asphalt shingle product being evaluated. Asphalt shingles of varying sizes, exposures, cut-outs, and seal-strip configurations and placements likely will have different test result values. Also, asphalt shingles' stiffness may vary based on differing raw materials and material compositions used during manufacturing. Therefore, test results for shingles with similar names but manufactured in different plants may differ.

ASTM D6381

The ability for an asphalt shingle product to resist the theoretical design uplift load that is acting on the sealant (derived using UL 2390) is determined using a separate test method, ASTM D6381, "Standard Test Method of Asphalt Shingle Mechanical Uplift Resistance." This test method contains two procedures referred to as Procedure A and Procedure B.

Procedure A measures a sealant strip's resistance to an edge-lift load (butt edge peeling force). Procedure B measures a sealant strip's resistance to a perpendicular load balanced between the front and back edges of the seal strip. Procedure A produces a lower result than Procedure B.

The procedure that applies to a specific asphalt shingle product depends on the asphalt shingle's design, geometry and rigidity.

When the measured uplift resistance of the sealant strip as determined using ASTM D6381 equals or exceeds the theoretical design uplift load determined by UL 2390, the specific asphalt shingle product being evaluated is considered to have passed the criteria for wind resistance at the basic wind speed used in the calculations. ARMA representatives have indicated the methodology and calculation procedure already include a safety factor of 4.3, so an additional safety factor is not required.

UL TGAH

UL has established a classification and listing system based on UL 2390 and ASTM D6381. This system is identified by UL Category Code TGAH, Prepared Roof Covering Materials, Asphalt Shingle Wind Resistance.

Within this UL classification and listing, asphalt shingle products that have demonstrated a resistance to a basic wind speed of 90 mph (40 m/sec) are identified as "Class D"; those passing at 120 mph (54 m/sec) are "Class G"; and those passing at 150 mph (67 m/sec) are "Class H." The figure compares the classifications from UL TGAH and classifications from UL Category Code TFWZ (UL 997 or ASTM D3161).

Asphalt strip shingle products classified according to UL Category Code TGAH are listed in UL's Roofing Materials Directory and the certifications section of UL's Web site. Also, specific classified products' package labeling will bear a UL list mark that indicates the specific classification that applies.

ASTM D7158

In November 2005, ASTM International published ASTM D7158, "Standard Test Method for Wind Resistance of Sealed Asphalt Shingles (Uplift Force/Uplift Resistance Method)." This standard combines the testing in UL 2390 and ASTM D6381 and incorporates a classification system similar to that contained in UL TGAH.

Over time, the single-reference standard approach of ASTM D7158 should be useful in assisting in the implementation and code acceptance of the new wind-resistance methodology for asphalt shingles with seal strips. Once the new methodology is implemented fully, ARMA has indicated ASTM D7158 will be used instead of UL 2390 and ASTM D6381, and UL 2390 and ASTM D6381 eventually may be dropped.

Limitations

The new wind-resistance methodology for asphalt strip shingles has several limitations.

First, the methodology applies only to asphalt strip shingles with sealant whether the sealant is factory-applied by the manufacturer or hand-tabbed during application. This methodology does not apply to unsealed asphalt shingles, including interlocking-type shingles, which do not have self-seal strips.

Secondly, the calculation procedure on which the methodology is based contains some assumptions that limit the applicability of the classifications. Specifically, the calculation procedure assumes ASCE 7 calculation variables of Ka=1; Kb=0.000285; a building height of 60 feet (18.3 m) or less; Exposure Categories A, B or C; and Building Use Categories I or II based on ASCE 7.

As a result, the new methodology's classifications Class D, G and H do not apply when a building's height is taller than 60 feet (18.4 m); has an Exposure Category D (flat, unobstructed areas); or has Building Use Categories III or IV. These conditions usually result in the highest wind-uplift loads and need for the largest resistances. For these conditions, the manufacturer should be consulted for the specific test variables (DCp, EI, L, L1 and L2) derived from new methodology from which a licensed design professional who is familiar with the methodology can perform project specific calculations and determine the appropriate product(s) to be used.

The L dimension

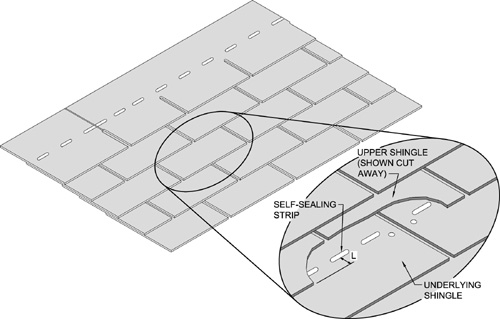

A critical dimension used in the new methodology's calculations is the distance from a shingle's butt edge to the front (downslope) edge of the seal strip of the underlying shingle in an installed system. (See Figure 2.) This dimension is referred to as "L" in the calculation.

Figure 2: L dimension for a three-tab strip shingle

NRCA has determined small variations in the L dimension significantly can affect the overall wind resistance of asphalt shingles using the new methodology. Mathematical models run by NRCA based on the new wind-resistance methodology show variations in the L dimension of as little as 1/4 of an inch (6 mm) can change the applied loads on a shingle up to about 14 percent. In these instances, if the L dimension is shortened by 1/4 of an inch (6 mm), the applied loads are decreased about 14 percent. Conversely, if the L dimension is increased by 1/4 of an inch (6 mm), the applied loads are increased about 14 percent.

Some variations in the L dimension typically are anticipated in the manufacturing and installation of asphalt strip shingles. For example, the material standard for organic-reinforced asphalt shingles, ASTM D225, allows for a 1/4 -inch (6-mm) variation in shingle size. An asphalt shingle's seal strip placement is known to vary by as much as the width of the seal strip, which typically is about 3/8 of an inch (10 mm) wide. Asphalt shingle application variances (coursing, alignment) are know to be about 1/4 of an inch (6 mm) or more depending on the specific asphalt shingle.

ARMA representatives have indicated the safety factor built into the methodology accounts for and "... far exceeds the reasonable variations that may be anticipated from either manufacturing dimensional variations or 'real world' application variations."

Also, coincidentally, the L dimension for many asphalt strip shingle products coincides with the width of a shingle's fastening (nail) zone. As a result, roofing contractors should seek asphalt shingle products with relatively large L dimensions to allow for proper application and reasonable application tolerances.

Moving forward

The new wind-resistance methodology for sealed asphalt strip shingles that has been developed by ARMA and asphalt shingle manufacturers represents a significant, scientifically backed change from the previous methods for determining wind resistances. It also provides substantiation for the testing and classification of asphalt shingles at higher wind speeds, which has been called for by code officials and the insurance industry.

Specific asphalt shingle products that have been tested and classified using this new methodology are listed under UL Category Code TGAH in UL's Roofing Materials Directory and in the certifications section of UL's Web site. It is important to note a listing in UL's directory or Web site only may apply to specific plant location and not necessarily all plants that make products of the same product name. Contact UL and asphalt shingle manufacturers regarding the applicability of listing to specific plant locations.

Also, the mathematical modeling conducted by NRCA based on the new wind-resistance methodology illustrates the importance of using quality manufactured asphalt shingle products and installing these products properly.

NRCA recommends users of asphalt shingles seek quality asphalt shingle products with printed and clearly defined installation instructions and application tolerance guidelines that are reasonably achieved by field crews.

Mark S. Graham is NRCA's associate executive director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.