Every roof system needs a flashing system that works. Poor flashings have allowed water to get in and under the best of roof systems. Sometimes, water entry is attributable to an improper design detail; other times, it may be a problematic application. Often, flashing material fails because of the demands of direct weathering, differential movement, inadequate attachment, cumulative movement or other stresses. Spray polyurethane foam (SPF) roof systems are unique because of the direct use of SPF material as the flashing system.

For example, a roof mechanic applying SPF material literally applies SPF up a wall, curb or projection to a prepared elevation and stops. Flashing sheets and fasteners are not required. The use of metal as a counterflashing over SPF material and coating also may be used. Currently, The NRCA Roofing and Waterproofing Manual, Fifth Edition's construction details call for SPF roof systems to use metal counterflashings. This article addresses what is happening in the field with SPF flashing details that do not incorporate metal counterflashings.

Background

The use of SPF on roof systems began in the 1960s. But getting SPF recognized by the industry as a viable roofing material took some time. As a result, a number of independent studies of SPF roof systems had been conducted during the 1980s and early 1990s; papers about the studies can be found in the proceedings of the second and third International Symposiums on Roofing Technology (log on to shop.nrca.net to purchase the proceedings). And the Spray Polyurethane Foam Division, now known as the Spray Polyurethane Foam Alliance (SPFA), developed a contractor accreditation program that continues to publish technical bulletins about the design, use and installation of SPF roof systems.

SPF contractors began to formalize installation practices for review and possible adaptation by NRCA during the mid-1990s. Along with SPF installation practices, a host of other technical issues had to be considered because different job-site conditions could be addressed with spray foam technology that were not necessarily standard practice with other roof systems, such as built-up, single-ply, metal, tile or shingles. One primary issue was how SPF roof systems incorporate flashing details, specifically whether counterflashings were needed. In 1996, NRCA published The NRCA Sprayed Polyurethane Foam-Based Roofing Manual, its first document addressing SPF roof systems.

As discussions ensued about SPF, the SPF segment of the roofing industry felt a need to examine the basic physical characteristics of SPF roof systems in service. It sought to discover the following: How does spray foam age, and does it retain its compressive strength or suffer a loss of mass and density?

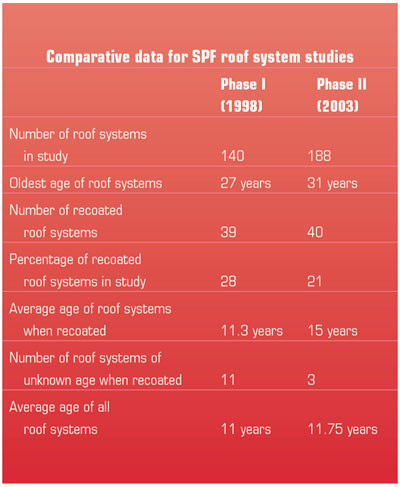

These questions led to an independent study funded by the National Roofing Foundation (NRF), a separate but related educational organization of NRCA. The study included 140 roof systems with an average age of 11.3 years; the oldest SPF roof system studied was 27 years.

I issued a report in 1998 that established the fact that SPF roof systems of varying ages all produced similar results for their retained physical properties of compressive strength and foam density. Various coating systems also were examined for mil thickness of base and top coat. In addition, moisture contents were determined from core samples; the average moisture contents ranged from 1.05 percent by weight to 6.4 percent depending on coating type.

The study did not specifically address SPF flashings nor their abilities to adhere to a variety of building materials, such as masonry, metal, wood, tile or other building components.

Current study

Flashing details often are a slighted aspect in roof system design. To truly understand each flashing detail takes time. If a flashing detail is not well-thought-out, a roofing contractor still has to provide something to complete the roof system. Many roofing contractors solve complete flashing details by installing a variety of materials, including metal, along with the bituminous or single-ply roof system they are installing.

Data from two National Roofing Foundation studies of spray polyurethane foam roof systems

In 2000, NRF began planning another field study of SPF as a flashing system. The objective was to study existing SPF flashing details and determine whether metal counterflashings are needed to ensure protection of SPF roof systems and coating systems. SPFA's technical details do not call for metal counterflashings; NRCA's roofing and waterproofing manual does.

The field study began in late 2001 and finished in September 2003. The study included 188 SPF roof systems of various sizes and shapes located in different climatic areas of the United States. The roof systems ranged from new to 31 years of age. About 21 percent of the SPF roof systems inspected had been recoated at the time of inspection; the average service time before recoating was 15 years.

The figure details the survey information for the 1998 and 2003 studies, including roof system age and recoating information.

SPF has the unique ability to solidly adhere to most, if not all, exterior building materials. A coating typically is applied to finish the detail; the coating may go further up the projection by 4 inches (102 mm) or more where possible. The photos show a series of SPF flashing details found in the field. Basically, the industry has learned SPF—when correctly applied to prepared surfaces and then coated—does not require metal counterflashings. SPF flashings were found to work well in the various regional climates of the United States. This includes roof-to-wall conditions, roof-to-roof transitions, penetrations and equipment supports.

Study summary

The NRF studies have shown SPF-based roof systems can provide long service lives, but maintenance is important—as it is with all roof systems. With correct procedures, SPF roof systems can be sustainable. The use of SPF as a flashing system was seen to easily accommodate many termination details found on roofs.

Specifically, it was noted SPF could adhere to the following materials:

- Masonry units

- Metal wall panels

- Metal flashings

- Concrete tilt-up panels

- Wood sheathing and board products

- Asphaltic flashing systems

- Single-ply flashing systems

There is a need to properly prepare, clean and prime all materials to which SPF is to be adhered. The use of SPF and appropriate coatings were seen to work quite well as a singular flashing system. The use of metal counterflashing was not seen to be required as part of an SPF roof system.

René M. Dupuis is president of Structural Research Inc., Middleton, Wis.

Photo 1: Standard metal counterflashing

Photos courtesy of Structural Research Inc., Middleton, Wis.

This photo shows a typical parapet wall with SPF and coating applied up the wall to the top of the plate. Galvanized sheet metal was formed and attached as a metal parapet cap with a drip edge. This field detail is topped with clay tile as part of the architectural finish needed. The use of metal as a parapet cap and counterflashing is similar to detail SPF-15 that can be found in The NRCA Roofing and Waterproofing Manual, Fifth Edition.

Photo 2: Base flashing for a nonwall supported deck

In this photo, you can see how an aged SPF base flashing has survived differential movement in the nonwall supported deck. Note the elastomeric sheets totally have parted across the deck portion of the expansion detail. The copper counterflashing has pulled apart at the joint. This 1988 SPF installation showed no distress and continues to function. This deck runs along a second-story wall that is not shown.

Photo 3: Roof-to-short-wall transition

This photo illustrates how a higher roof transitions to a slightly lower roof that required a short transition wall to the adjoining lower roof. A light-gauge metal wall panel and cap previously formed this transition. This detail was installed in 1977 and recoated in 2002.

Photo 4: SPF roof-to-metal-roof transition

A roof-to-roof transition is shown in this photo, which details how SPF was used to solve a difficult tie-in for two roof systems. The existing metal flashing detail was covered with SPF and coated. The SPF transition detail also makes a right angle and continues to the right as a tie-in to the metal roof system that was added to the existing structure. The SPF tie-in was installed in 1991.

Photo 5: Interior gutter system

This photo shows a large existing warehouse complex that had been reroofed with SPF in 1991. The existing metal roof and interior gutter system were overlayed with 1 1/2 inches (38 mm) of SPF and coating. The existing metal flashing system was secured and covered with SPF. No new metal flashings or counterflashings were added. The interior gutters also were covered with SPF as shown.

Photo 6: SPF roof-and-wall transition

A complete roof-and-wall transition with SPF is shown. No metal flashing has been used on this 1997 installation. All the pre-existing metal flashing now is encased by SPF. No new metal was used. The divider wall between the two lower roof systems has been covered with SPF and coating to complete the system.

Photo 7: SPF wall flashing

The large lower main roof of this distribution center is broken up by a three-story masonry block wall. As shown in the photo, the expansion joint in the block wall is active. The SPF reroofing material covers all pre-existing metal flashing. The SPF flashing now reaches above the original metal counterflashing with the coating going above the SPF by at least 4 inches (102 mm). There are no cracks or spalling of the SPF; the coating is functioning as a counterflashing over the SPF at the top of the cant as shown.

Photo 8: SPF low-wall flashing application

In some instances, the metal cap flashing system completely is covered by the SPF system with no loss in performance. This photo shows a low masonry parapet wall and metal cap system covered with SPF and coating along the perimeter of a 1998 installation.

Photo 9: Equipment support curbs

Both low and high equipment support curbs were observed as shown in Photos 9 and 10. In this photo, the high curb appears to have been extended up with a slightly smaller curb from the original base and flashed with SPF and coating.

Photo 10: Equipment support curbs

Low curbs in this photo were observed to have been treated the same way as in Photo 9 with no functional difference using SPF and coating. No metal counterflashing was used nor does it appear to be needed.

Photo 11: Equipment support columns

SPF roof systems often were found to have no need for pitch pans or separating support columns that are structurally sound and tied to a roof deck. This photo shows a heavy steel angle support stand that is directly flashed with SPF and coating into the SPF roof system. The 1992 flashing installation appears to be watertight and serving its purpose.

Photo 12: SPF flashing

Photo 13: SPF flashing

The National Roofing Foundation studies observed numerous flashing details where pre-existing metal flashing had been installed. As shown in Photos 12 and 13, SPF easily can adapt to many rooftop details by being overlaid onto an existing prepared substrate. Existing metal flashings may remain and be totally enclosed or left exposed as needed.