Editor's note: The following was adapted from the paper "The Correlation Between Hail Resistances and the Physical Properties of Fiberglass Shingles," which was written by the authors and presented in February at the 2013 International Roofing Expo® in San Antonio.

Fiberglass-reinforced asphalt shingles are a primary roofing material used on steep-slope roof systems in the U.S. Fiberglass shingles are used in a variety of applications, including single-family homes, multitenant structures and commercial buildings. However, during hail events, fiberglass shingles can fail, resulting in significant expenses often borne by the insurance industry, building owners and homeowners. This recurring loss exposure has resulted in discussions within the insurance industry as to how claims involving hail damage to fiberglass shingles could be reduced.

Jim D. Koontz & Associates Inc., Hobbs, N.M., recently conducted a study in 2012 to determine the role physical properties of fiberglass shingles play in hail resistance. Following is an overview of the study results.

Background

Fiberglass shingles were introduced to the roofing industry during the late 1970s and early 1980s as a substitute for conventional organic, three-tab shingles. These new fiberglass shingles relied on the use of fiberglass mats to be an "equal to" or "better than" product compared with conventional organic mats.

In 1998, the Texas Department of Insurance instituted a program for homeowners to receive discounted insurance rates if their residences were covered with hail-resistant roofing materials. The methodology for determining hail resistance comprised testing roofing products according to Underwriters Laboratories (UL) Inc. test procedure 2218, "Impact Resistance of Prepared Roof Covering Materials," which involves dropping steel balls onto various roofing targets. Products subjected to the testing are given a Class 1, 2, 3 or 4 rating. Class 4 is the highest rating and intended to simulate the impact energy of 2-inch-thick hail.

If a homeowner installs a roofing product that is UL-tested and deemed to be hail-resistant, the homeowner receives a discount on his or her insurance premiums. Insurance carriers and homeowners often assume if a roofing shingle obtains a UL 2218 Class 4 rating, it will have a higher degree of hail resistance. Several shingle manufacturers tout their impact-resistant shingles in their marketing literature; however, the same manufacturers exclude hail of any size or diameter from coverage in their written warranties.

The marketing of "hail-resistant" shingles raises the questions: Do UL 2218 Class 4-rated shingles provide some degree of hail resistance? And do UL 2218 Class 4-rated shingles retain sufficient physical properties to provide hail resistance during a product's service life?

Following a hail event in Dallas in 2011, a Roofing Industry Committee on Weather Issues (RICOWI) study suggested UL 2218 Class 4-rated shingles may provide some improved hail resistance when compared with roofing products not rated for hail impact.

RICOWI reported the following factors may affect the relative hail resistance of a fiberglass shingle product: hail size and angle of impact; roofing material age; precise point of impact; and whether more than one layer of shingles is in place.

What is hail damage?

An important issue when considering the hail resistance of fiberglass shingles is what constitutes hail damage. There is no widely accepted definition. Homeowners, shingle manufacturers, roofing professionals and insurance carriers have different views regarding what constitutes hail damage, often depending on their own financial interests.

For example, some would define shingle damage as granule loss caused by hail impact. Others dispute this definition. Granule loss occurs during roof system installation, when someone walks across a roof, during every wind and rain event, and as part of the typical aging process. Is it correct to call granule loss during a minor hail event hail damage? Or should it be classified as typical wear and tear?

Other definitions of hail damage often used include the loss of water-shedding capability and whether the effect of the impact will result in decreased shingle life span. Further complicating the issue is the fact some possible effects of hail impact may not be immediately visible.

Finally, there is a debate whether only visible changes to shingles, often referred to as cosmetic damage, constitute hail damage regardless of whether there is any resulting loss in water-shedding capabilities or reduction in service life. This dispute often arises in the context of insurance claims. Different parties may have different perceptions regarding what constitutes hail damage to a fiberglass shingle.

Building codes

The 2009 International Building Code® (IBC) and 2009 International Residential Code® require fiberglass asphalt shingles comply with ASTM D3462, "Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules." Within the IBC for low-slope roof systems (slopes less than 2:12), roof coverings are required to resist some degree of impact damage. Impact resistance as listed by the IBC includes various types of steel impact-type procedures. Therefore, steep-slope roof coverings or fiberglass shingled roofs are not subject to this requirement.

A number of physical properties for fiberglass shingles are included within ASTM D3462, including tear resistance, granule adhesion, pliability, net mass of shingle, net mass of fiberglass mat and others.

Our laboratory tests

For our study, 11 new fiberglass shingles were acquired from material suppliers. The shingle samples included six laminate and five three-tab fiberglass shingles. Within the test group were four modified asphalt, three-tab and laminate shingles. Five of the shingles tested were designated as having impact resistances of UL 2218 Class 4. The marketing literature for all the new shingles tested listed compliance with ASTM D3462.

Five aged and exposed shingles taken from various roofs in Hobbs, N.M., also were tested. The five aged roofs were about 10 years old and consisted of two three-tab and three laminated shingles. Marketing literature for the aged shingles was not available.

The shingles initially were tested for the following physical properties:

- Net mass (ASTM D3462)

- Desaturated mat weight (ASTM D3462)

- Granule adhesion (ASTM D4977, "Standard Test Method for Granule Adhesion to Mineral Surfaced Roofing by Abrasion")

- Tear resistance (ASTM D1922, "Standard Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method")

- Tensile strength (ASTM D146, "Standard Test Methods for Sampling and Testing Bitumen-Saturated Felts and Woven Fabrics for Roofing and Waterproofing") Pliability at 73 F and 40 F (ASTM D3462)

Net mass

Following ASTM D3462, samples were carefully measured and weighed. The net product mass for each shingle was recorded. The shingle masses varied from 73½ pounds per 100 feet to 128.3 pounds per 100 feet. All the samples exceeded the net mass requirement under ASTM D3462 of 70 pounds per 100 feet.

Desaturated mat weight

Following ASTM D3462, the shingle samples were desaturated to remove all asphalt and granules using a solvent extraction procedure. Once the asphalt and granules were removed, the fiberglass mats were oven-dried and carefully weighed on an analytical balance. The dry, desaturated mat weights ranged from 1.62 pounds per 100 feet to 2.21 pounds per 100 feet. All the samples exceeded the ASTM D3462 mat weight requirement of 1.35 pounds per feet.

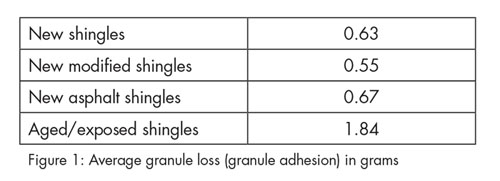

Granule adhesion

Shingles manufactured to comply with ASTM D3462 were tested following ASTM D4977. Using this test, the maximum amount of granule loss allowed is 1 g. Two of the 11 new shingles tested—one modified asphalt and one regular asphalt shingle—failed to comply with this requirement.

Figure 1: Average granule loss (granule adhesion) in grams

Four of the five aged shingles did not meet this requirement. Most likely, as shingles age and the asphalt used to adhere the granules increases in softening point, granule adhesion decreases. All but one of the five older shingles had a granule loss greater than 1 g (see Figure 1).

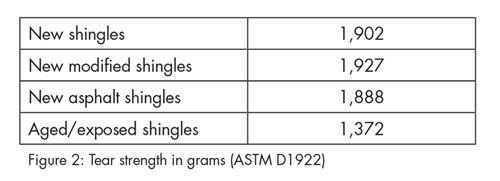

Tear resistance

Each of the 16 shingles was tested for tear resistance according to ASTM D1922, which uses the pendulum method to determine tear resistance. Eleven of the 16 samples were new shingles and marketed to be in compliance with ASTM D3462, which requires new shingles to have a tear resistance of 1,700 g. Of the 11 new shingles tested, seven met the ASTM D3462 requirement and the two building code requirements. All five of the aged shingles failed, falling below the 1,700-g requirement (see Figure 2).

Figure 2: Tear strength in grams (ASTM D1922)

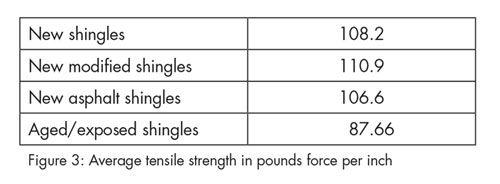

Tensile strength

Using ASTM D146, all the shingles were tested for tensile strength. Four of the 11 new shingles were modified asphalt. Samples measuring 1 by 6 inches were tested in tension. A jaw separation rate of 12 inches per minute was used in the tensile tester. The shingles' tensile strength varied from 78.9 pounds per inch for a three-tab shingle to 138.3 pounds per inch for another three-tab shingle. The modified asphalt shingles displayed an average tensile strength of 110.9 pounds per inch. The asphalt shingles displayed an average tensile strength of 106.6 pounds per inch. All the aged shingles had an average tensile strength of 87.66 pounds per inch (see Figure 3).

Figure 3: Average tensile strength in pounds force per inch

Pliability at 73 F and 40 F

When testing shingles for pliability, samples were bent at a 90-degree angle under defined conditions. Pliability assessment is based on the shingle's resistance to the formation of surface fissures or fractures. The test is performed by bending the samples over a mandrel with a 1-inch-wide radius that forms part of a 6-inch-wide block. The test is conducted at room temperature—73 F plus or minus 4 degrees. Failure is defined according to ASTM D3462 as: "Cracking of the filled coating asphalt which exposes the reinforcement of the shingle. The cracking shall be visible to the naked eye when the specimen is viewed in the bent condition."

For purposes of this study, our company tested the shingle samples on the weather side at room temperature and 40 F. The test was performed in the machine and cross-machine direction. The initial results from the testing followed visual examination requirements per ASTM D3462.

All the new shingles passed the pliability test at room temperature. Failure occurred in two of the five aged samples at room temperature. When the pliability test was performed at 40 F, nine of the 11 new shingles passed the test. Only one of the five aged shingles passed the test at 40 F. Obviously, the aged asphalt in the older shingles had become somewhat brittle and was more subject to breakage.

Observations

Shingle impact

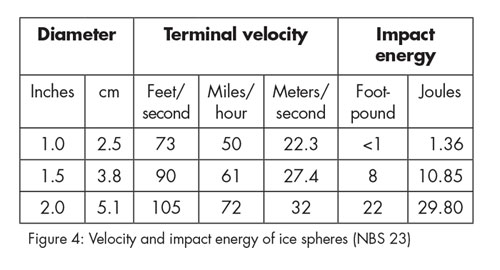

Following National Bureau of Standards, Building Science Series No. 23, all 11 new shingles and five aged shingles were impacted with ice spheres having 1-, 1 1/2 - and 2-inch-wide diameters. The ice spheres were propelled using a pneumatic launcher at velocities listed by the National Bureau of Standards.

Figure 4: Velocity and impact energy of ice spheres (NBS 23)

As shown in Figure 4, there is a significant increase in impact energy when the ice sphere diameter is increased from 1 to 2 inches. Impact energy increases exponentially with weight and free fall or terminal velocity. All the shingle targets were subjected to water spray at 40 F. The purpose of the water spray was to attempt to replicate the most severe conditions that may occur during a hail event. All the targets initially were impacted at a 90-degree angle.

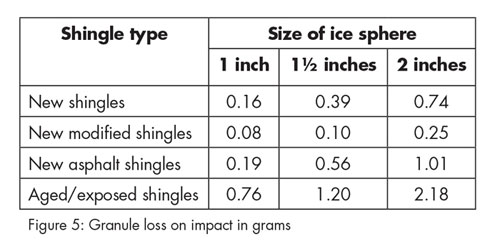

Granule loss on impact

Figure 5: Granule loss on impact in grams

When examining the quantity of granule loss and the impacting ice spheres' sizes, it generally was observed that when larger diameter ice spheres impact shingles, the result is a greater loss of granules. On average, the modified asphalt shingles exhibited the lowest amount of granule loss upon impact, and the older shingles had a higher amount of granule loss than the new shingles (see Figure 5). The aged asphalt shingles have a greater propensity to lose granules, most likely because of hardened and brittle asphalt.

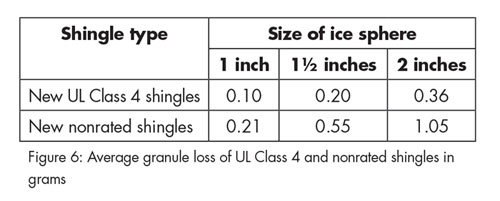

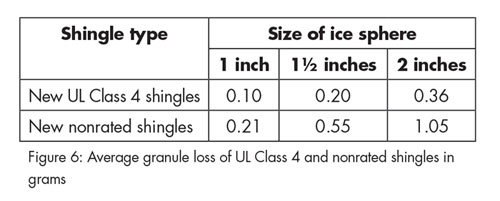

Five of the 11 new shingles with a UL 2218 Class 4 designation were tested for impact with 2-inch-wide diameter steel spheres. The UL 2218 Class 4-rated shingles clearly have a lower granule loss rate than the nonrated shingles (see Figure 6).

Figure 6: Average granule loss of UL Class 4 and nonrated shingles in grams

Granule loss vs. granule adhesion

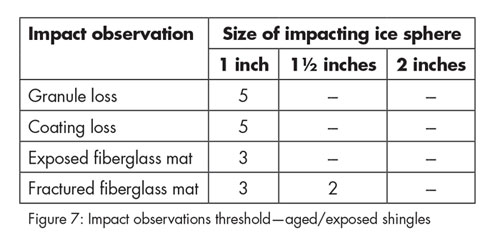

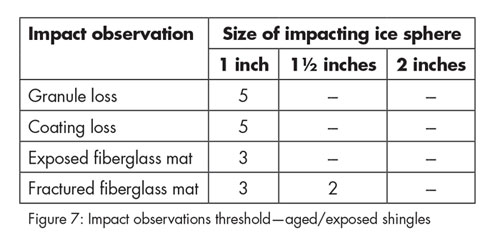

A comparison was made regarding the amount of granules lost in the granule adhesion test and amount of granule loss as a result of ice sphere impact. For purposes of this analysis, the cumulative amount of granules lost from impacts of 1-, 1 1/2- and 2-inch-wide ice spheres was used (see Figure 7). It appears there is some positive correlation between greater granule adhesion properties and granule retention during hail-impact events.

Figure 7: Impact observations threshold—aged/exposed shingles

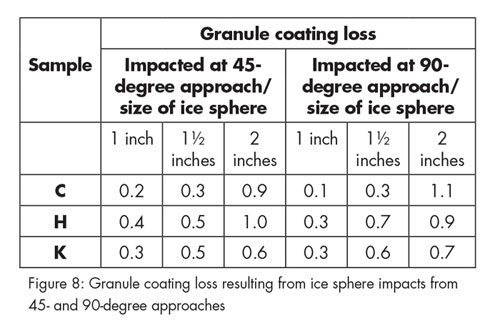

Impact angle

Three shingle samples were impacted at the sample surface at 45- and 90-degree angles using 1-, 1 1/2 -and 2-inch-wide ice spheres. The dislodged granules were collected and weighed. The purpose of impacting the samples at different angles was to see whether there was any difference in the shingles' granule loss based on the angle of ice sphere impact. The 45-degree angle impact would simulate an ice sphere accompanied by a strong horizontal wind. The overall net results showed no substantial difference between a 45-degree and 90-degree impact angle (see Figure 8).

Figure 8: Granule coating loss resulting from ice sphere impacts from 45- and 90-degree approaches

Microscopic examinations

Currently within some standards, microscopic assessment use is referenced. However, within the roofing industry, specific written procedures for microscopic examination have not been developed or approved. Each time samples are viewed microscopically, the laboratory uses a viewing device with the same focal length, magnification and light source. Slight variations in these parameters can produce substantial visual variances in photographic documentation.

The selected shingles sampled were microscopically examined and photographed before they were impacted with 1-, 1 1/2- and 2-inch-wide ice spheres. The samples then were re-examined to document the effects of the impacts. Four types of observations were identified and categorized per our company's designation.

Granule and coating loss

As a result of the impacts, granules clearly were dislodged from the shingles' surfaces. The dislodged granules were collected and weighed. Each shingle sample also was microscopically examined for granule and coating loss, visible exposure and fiberglass mat fractures.

Of the 11 new shingles, 10 lost granules as a result of impact with 1-inch-wide ice spheres. One sample did not lose granules until impacted with the 1 1/2-inch-wide ice sphere. Asphalt coating loss occurred in six of the samples impacted with a 1-inch-wide ice sphere. Asphalt coating loss occurred in four of the samples impacted with a 1 1/2-inch-wide sphere. And asphalt coating loss occurred in one of the samples impacted with a 2-inch-wide ice sphere.

Exposed fiberglass mat occurred in four of the samples when impacted with 1-inch-wide ice spheres; six samples at 1 1/2-inch-wide ice spheres; and one sample with a 2-inch-wide ice sphere.

Fractures in the fiberglass shingle mat occurred in one sample with a 1-inch-wide ice sphere. This particular sample was taken from a UL 2218 Class 4-rated shingle. Five samples were fractured with 1 1/2-inch-wide ice spheres. Three shingle samples were not fractured until impacted with 2-inch-wide ice spheres.

Figure 9: Impact observations threshold—new shingles

Two of the 11 samples did not fracture when impacted with 2-inch-wide ice spheres; the two samples were UL 2218 Class 4-rated. Of the four modified shingles tested, only one shingle did not fracture when impacted with 2-inch-wide ice spheres (see Figure 9).

All five older shingles lost granules and asphalt coating after impact with 1-inch-wide or greater ice spheres. Three were fractured with 1-inch-wide ice spheres. Two were not fractured until impacted with 1 1/2-inch-wide ice spheres.

UL testing

Three new shingle samples were subjected to additional steel sphere impact per UL 2218. Sample A is a laminated modified shingle; sample B is a modified three-tab shingle; and sample J is an asphalt three-tab shingle. Samples A, B and J are marketed with a UL 2218 Class 4 rating and in compliance with ASTM D3462. All three samples were impacted with a 2-inch-wide diameter steel sphere, generating about 22 feet per pound of impact energy at room temperature.

Figure 10: Visual inspection and water column leakage test results (ASTM D5635)

Following impact, all three samples were placed on a light table. Light was not observed passing through any of the samples at the points of impact. All three samples were subjected to a 20-inch-tall water column test for 15 minutes per ASTM D5635, "Standard Test Method for Dynamic Puncture Resistance of Roofing Membrane Specimens." Samples A and J passed the test. Leakage was observed in Sample B (see Figure 10). Under UL 2218 Class 4, the shingles only would be subjected to a visual examination.

Comparative analysis

When comparing threshold fracture damage of new shingles and various physical properties—net mass, desaturated mat weight, granule adhesion, tear resistance, tensile strength and pliability—the role of each physical property varies.

Based on current data, there does not appear to be a clear correlation between tear resistance and impact resistance. Increased tensile strength appears to provide some degree of higher-impact resistance. Pliability properties do not offer a clear picture of impact resistance. And the correlation between product net mass and impact resistance also does not appear to be a factor in fracture resistance for new shingles. Higher dry mat weights appear to be helpful for resisting fractures during impact.

Conclusions

As a result of our tests, we determined the following:

- As shingles age, hail resistance substantially diminishes.

- UL-rated shingles have lower granule loss.

- UL-rated shingles may have varying hail-impact performances.

- Modified shingles may offer some degree of increased hail-impact resistance.

- Increased mat tensile strength may assist in hail-impact fracture resistance.

- The role of tear strength is unclear.

Recommendations

UL testing and classification may, in some cases, provide a false sense of hail-resistance performance. If a shingle is touted as hail-resistant per UL 2218 Class 4, shingle manufacturers should provide some specific range of hail resistance, such as resistance to 1-, 1 1/2- and/or 2-inch-wide hail, and issue a corresponding warranty for a defined hail size.

The roofing industry, state regulators, insurance companies and roofing manufacturers can help alleviate the ambiguity of what constitutes hail damage by developing and providing a clearer definition, measurement or determination of the term hail damage. Building codes also should provide requirements that in hail-prone geographical areas, enhanced shingles with an established increased degree of impact resistance be required.

Damage to fiberglass shingles is a major factor in the roofing and insurance industries. It is clear additional research and review of this subject is warranted by all parties.

Jim D. Koontz, P.E., RRC, is president of Jim D. Koontz & Associates Inc., Hobbs, N.M., and Troy L. White, P.E., is an associate of Jim D. Koontz & Associates.