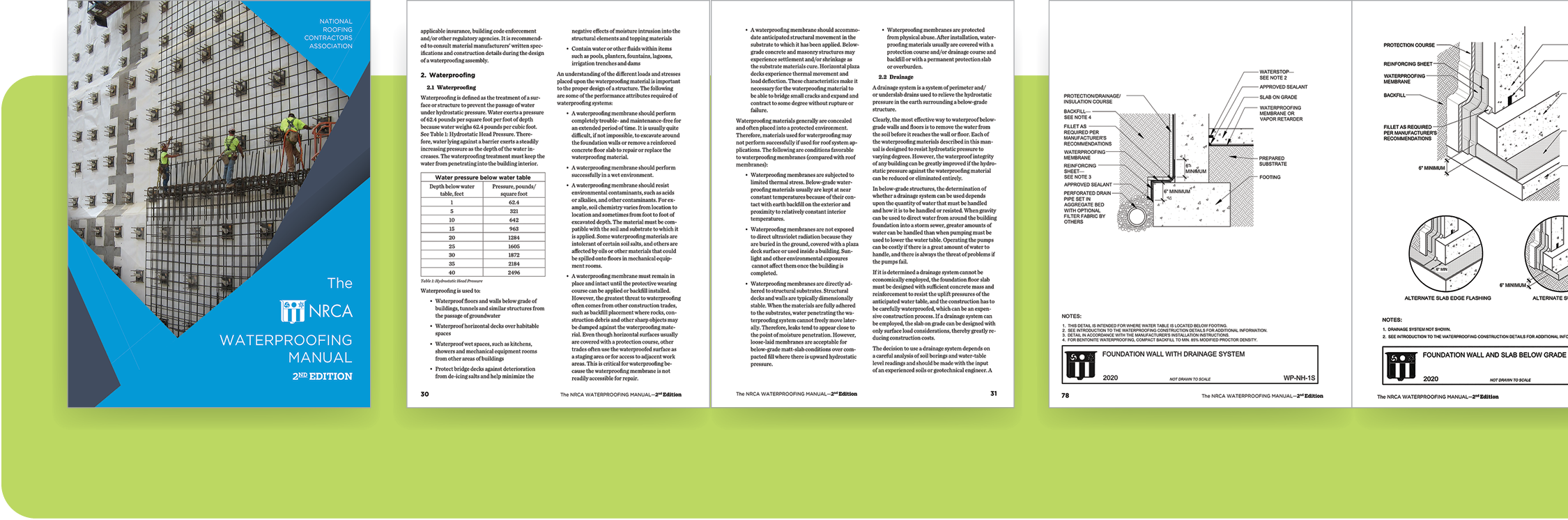

In November 2020, NRCA released The NRCA Waterproofing Manual—2nd Edition, which provides up-to-date NRCA best practices applicable to the design and installation of waterproofing and dampproofing systems in North America. It serves as a valuable reference for waterproofing and dampproofing system designers and installers. The NRCA Waterproofing Manual—2nd Edition updates and replaces The NRCA Waterproofing Manual.

The manual is divided into the following parts:

- The General Project Considerations section provides an overview of general information concerning the design and installation of quality waterproofing systems.

- In-depth technical information concerning the design and installation of quality waterproofing and below-grade dampproofing systems is found in the Waterproofing and Dampproofing Guidelines and Waterproofing Construction Details sections. These sections form the core of the manual.

- Appendixes contain sample forms for qualifying potential waterproofing contractors, keeping track of project documentation and assignments during a pre-job conference, and testing waterproofing membrane integrity. This section also includes discussions of testing waterproofing membrane integrity using water-test procedures and electronic leak-detection methods and associated NRCA recommendations. The appendixes also provide a glossary of terms used in the manual.

Waterproofing Task Force

NRCA’s Waterproofing Task Force primarily was responsible for researching and analyzing topics and developing the manual’s text, figures and construction details. The task force was composed of practicing waterproofing contractors and manufacturers of waterproofing materials. The task force conducted its work between July 2018 and March 2020. It started with three members and increased to five by the time the task force finished its work.

The task force was in contact with a number of U.S. waterproofing industry subject matter experts who assisted the task force by answering questions and providing review comments. NRCA’s Technical Operations Committee and Executive Committee provided review comments and guidance.

During its first meeting, the task force identified specific objectives and principles that would be realized in the updated manual. These initial decisions helped outline and explain the revisions that were made. The task force decided to direct its efforts to accomplish the following objectives:

- Stress the importance of following manufacturers’ instructions

- Update and significantly expand information about below-ground waterproofing

- Update and significantly expand information about blind-side-applied waterproofing materials and applications

- Update and significantly expand information about waterproofing materials, waterproofing accessories and waterstop materials and their applications

- Update and expand information about waterproofing maintenance and repairs

Manufacturers’ instructions

Task force members agreed it was important the updated manual emphasize the importance of following manufacturers’ installation instructions. The legacy text extensively references manufacturers’ instructions as does the revised and new content. Waterproofing professionals work with an ever-growing variety of waterproofing materials used in increasingly specialized waterproofing applications. It is important they understand and closely follow material- and application-specific manufacturers’ instructions.

Many waterproofing products are proprietary and have to be handled by installers who are familiar with product- and system-specific installation instructions. Waterproofing manufacturers commonly require specific training and/or certifications for applicators of proprietary waterproofing systems.

It might seem following manufacturers’ instructions is obvious when installing waterproofing systems; however, model building codes include scarce provisions addressing requirements for waterproofing and dampproofing applications, and few standard specifications exist for commonly used waterproofing and dampproofing materials and applications. This is in contrast with roofing materials and roof system applications, which are addressed by a considerably larger body of standard specifications, practices and guides and, in turn, are substantially regulated by model building codes that reference those standards.

Manufacturers of roof, waterproofing and dampproofing systems provide installation requirements installers must follow for installed systems to be eligible for manufacturers’ warranties. With roof systems, manufacturers’ requirements typically exceed model building code requirements that establish the minimum legal requirements for roof system installations. With waterproofing and dampproofing systems, there are few minimum requirements provided in model building codes. Building owners rely to a greater extent on the applicators following manufacturers’ requirements to obtain correctly installed systems.

Below-ground waterproofing

The task force concluded below-ground waterproofing applications generally are not well-understood among the design community and manufacturers are not adequately addressing this. Accordingly, information in the NRCA manual about below-ground waterproofing applications is revised and significantly expanded. The following is not an exhaustive list but outlines most of the key revisions:

- Recommendations are updated for waterproofing materials appropriate for use beneath slabs below grade over reinforced concrete substrates and for use beneath slabs below grade over compacted earth substrates.

- Recommendations are updated for waterproofing materials appropriate for application to the positive side of walls below grade. Recommendations for application to accessible walls are addressed separately from recommendations for blind-side applications.

- NRCA does not recommend installing below-grade expansion joints. If a below-grade expansion joint is required, the installer should contact the waterproofing membrane manufacturer for specific recommendations.

- When below-grade waterproofing is used in a gas-barrier application, NRCA recommends specifying a gas venting system appropriate for site conditions and smoke testing to verify gas-barrier integrity.

- Below-ground waterproofing construction details are designated as suitable for hydrostatic conditions or nonhydrostatic conditions. Details designated as suitable for hydrostatic conditions, denoted “WP-H-” followed by a number, apply when below-ground walls and floors must be designed with sufficient strength to resist the hydrostatic pressure of the anticipated water table. Details designated as suitable for nonhydrostatic conditions, denoted “WP-NH-” followed by a number, apply if the water table is located below the building foundation.

Blind-side waterproofing

The NRCA Waterproofing Manual referred to bentonite waterproofing as one of the few products capable of being blind-side-applied by attaching it to lagging before structural concrete placement. Currently, designers and installers are able to select from a variety of waterproofing materials appropriate for blind-side application, including bentonite-based materials.

Bentonite materials that were used for waterproofing in 2005 have been replaced by composite waterproofing sheets that join bentonite with other components. The section addressing bentonite waterproofing is significantly revised and addresses two types of commercially available products.

One type of composite sheet bentonite waterproofing product consists of two high-strength geotextile facings and bentonite compound core. The geotextiles are interlocked by needle-punching through the core to support and protect it from premature hydrating expansion and incidental damage. Another type of composite sheet bentonite waterproofing product consists of granular bentonite and adhesive bonded to a thermoplastic sheet. Both materials require proper confinement and, therefore, only are appropriate for below-ground applications.

A distinct type of composite bentonite-bearing waterproofing sheets appropriate for blind-side applications as well as above-grade split-slab plaza deck applications is addressed separately. These sheets are constructed with two principal components: an engineered hydrophilic material incorporating bentonite and reinforced thermoplastic sheet. The sheets are designed with selvage edges intended for hot-air welding during installation. The manual refers to these materials as composite (hydrophilic polymer and thermoplastic) sheets.

Composite grout-injected sheet membranes are specialized systems intended for waterproofing below-grade structural shotcrete walls. With increasing use of structural shotcrete for foundation construction, these systems also are increasingly being used and are included in the updated manual. Composite grout-injected sheet waterproofing membranes are constructed with three primary components: laminated sheet made up of thermoplastic film backing, open synthetic mesh and non-woven geotextile; grout injection ports; and polyurethane grout.

Blind-side-applied laminated sheets provide a continuous cavity that is completely filled with polyurethane grout injected through pre-installed injection ports after structural shotcrete placement.

Separately, composite (adhesive and thermoplastic) sheets are addressed. These products are specifically designed for blind-side waterproofing applications.

New construction details are included for composite (hydrophilic polymer and thermoplastic) sheet membranes, composite (adhesive and thermoplastic) sheet membranes and composite grout-injected sheet membranes.

In the section addressing waterproofing substrate, discussions of concrete, shotcrete, and compacted soil and drainage rock substrates were significantly revised. A section addressing excavation support systems was added.

More new materials

New information has been added about a number of waterproofing materials, waterproofing accessories and waterstop materials.

In addition to composite grout-injected sheet membranes and composite (hydrophilic polymer and thermoplastic) sheets discussed earlier, composite (adhesive and thermoplastic) sheets are included. These products are specifically designed for blind-side applications against concrete, shotcrete and lagging substrates. They are made up of two or more materials laminated together to form a composite sheet. The principal components are a water-impermeable thermoplastic sheet and an adhesive. Other sheet components may include reinforcing scrims and weather-resistant coatings. Some products include a self-adhesive selvage edge.

A new section on reinforced resin traffic coatings has been added to address polymethylmethacrylate (PMMA) and polyurethane-methacrylate (PUMA) traffic coatings. The liquid components require the addition of a catalyst to induce curing. PMMA resin-based coatings require polyester fabric reinforcement to provide crack-bridging ability and mechanical strength. PUMA resin-based coatings benefit from increased crack-bridging ability and toughness imparted by their polyurethane component and may not require reinforcement. Reinforced resin traffic coatings generally are mechanically tougher, faster-curing and characterized by shorter pot life as compared with elastomeric traffic coatings.

Discussion of waterproofing protection courses is revised and expanded. Asphalt-based protection boards and asphalt-coated protection sheets are addressed in greater detail than in the previous manual. Use of geocomposite drainage products in protection courses applications also is discussed.

A variety of waterstop materials are discussed in greater detail. Waterstops are installed at cold joints in concrete walls and slabs, walls and footings, and at vertical joints in concrete work to provide secondary—to waterproofing membranes—protection against water infiltration.

Maintenance and repairs

Although the information presented in The NRCA Waterproofing Manual—2nd Edition primarily addresses new construction and replacement waterproofing situations, the manual includes updated and expanded information about waterproofing maintenance and repair methods.

Discussion of chemical grout injection for sealing leaking cracks in concrete is updated. NRCA recommends designers reference ASTM D8109, “Standard Guide for Waterproofing Repair of Concrete by Chemical Grout Crack Injection,” published in 2017, when specifying concrete wall and slab waterproofing repairs using chemical grout injection.

Bentonite grout injection repairs are addressed in a new section. Bentonite grout injection is designed to create a dense, water-impermeable mass on the exterior surface of the foundation wall in adjacent soil or under the concrete slab. Bentonite grout may be injected from grade around the structure without excavating or may be injected through holes drilled in concrete walls or slabs.

Information about electronic membrane integrity test methods for facilitating repairs was added in a new appendix.

Sought-after information

The NRCA Waterproofing Manual has been one of NRCA’s best-selling publications, and with the current demand for waterproofing best practice information, the updated edition should enjoy similar popularity.

If you are involved with designing and installing waterproofing systems, I encourage you to become familiar with the revised manual.

The NRCA Waterproofing Manual—2nd Edition and The NRCA Waterproofing Manual—2nd Edition Construction Details: CAD Files are available for purchase from shop.nrca.net. NRCA members can download the manual as a PDF document for free.