According to statistics culled from the National Oceanic and Atmospheric Administration's severe weather database, the number and severity of hailstorms in the U.S. has increased significantly during the past decade. It's generally recognized within the insurance industry that hail-related claims are rising in number and value. As a result, organizations such as the Roofing Industry Committee on Weather Issues Inc., Institute for Business and Home Safety, and FM Global have focused more of their efforts into characterizing, measuring and understanding hail damage.

There also is a significant amount of discussion within the roofing industry regarding how to characterize hail damage and predicting hail resistance. Hail is a natural phenomenon with many variables, such as size, shape, surface roughness and speed, which can reach up to 100 mph. To further the roofing industry's understanding of hail, our company, GAF, Parsippany, N.J., has been conducting research focused on ice ball testing of various roof systems to reveal the effects substrate and attachment methods have on single-ply impact resistance.

Defining failure

Testing for hail resistance is a complex topic. When combined with other meteorological factors such as ambient temperature, wind speed and direction, and rooftop temperatures immediately preceding a storm, it becomes clear predicting hail damage can be quite difficult.

In addition to prediction difficulties, there is the issue of defining hail damage. Definitions can range from dimpling to puncturing through a membrane, but there has been relatively minor discussion about damage to a membrane substrate. Based on an analysis conducted by SPRI and the Asphalt Roofing Manufacturers Association, single-ply membranes represent more than 50 percent of the U.S. commercial roofing market; TPO membranes represent a majority of those.

In general, field examinations of hail damage and laboratory tests that measure impact resistance have focused on membrane damage, which includes splits, punctures, fractures, etc., and in the case of single-ply membranes, damage specifically above the fasteners. It seems prudent to better understand the impact resistance of not just a membrane but also an entire roof system.

Our preliminary work indicates large ice ball impacts on TPO or PVC membranes directly above fastener plates result in membrane puncture. Screw heads have sharp edges to the slots that cut into the membrane. Ice balls, similar to actual hailstones, are deformable and appear to compress the membrane into the heads of screws, resulting in splitting.

FM 4473, "Test Standard for Impact Resistance Testing of Rigid Roofing Materials by Impacting with Freezer Ice Balls," failure criteria relates to membrane failure because cracks to the reinforcement fabric in the case of TPO or PVC membranes can lead to leaks. However, many field investigations such as those performed by the Roofing Industry Committee on Weather Issues have noted dimples in the field areas of membranes, which implies substrate damage. Indeed, many roofing professionals specify the use of rigid cover boards in high-frequency hail areas such as Texas and Oklahoma.

Our research focused on testing various types of substrate and attachment methods. The intent of the study was to identify overall trends, so only one brand of each material was tested. Two-inch diameter freezer ice balls were used, closely following FM 4473's test method.

A 1- by 1-foot wood deck was used as backing for the test samples, which were the same dimensions as the deck. The target was hit with two consecutive ice balls at a target kinetic energy between 32.2 and 35.4 J (23.75-26.13 foot/pound, a criteria for Class 4). This corresponds to a 2-inch diameter ice ball falling at a terminal velocity of about 75 mph. The consecutive hits, with a maximum distance of 1/2 of an inch between impacts, are done to simulate multiple hail hits at the same point. Actual hailstorms can be extremely intense with large numbers of hailstones hitting a relatively small area.

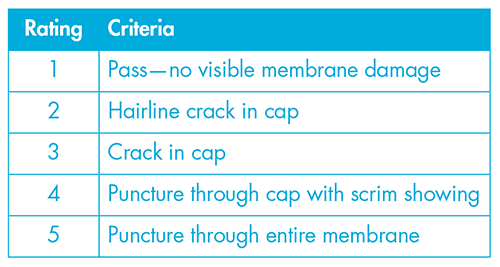

Figure 1: Rating criteria used to characterize impact of a 2-inch ice ball on a TPO membrane |

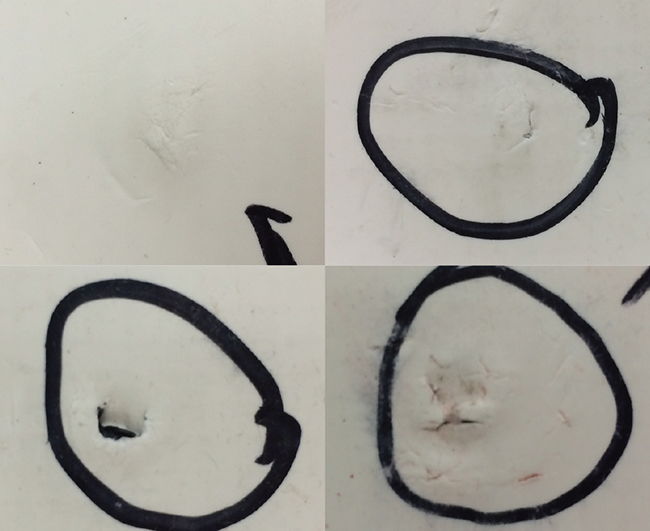

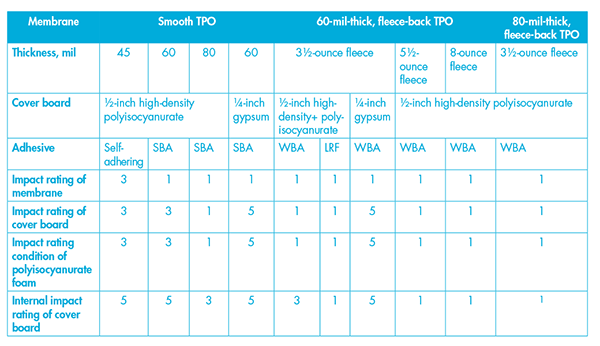

The result of the membrane impact was rated in terms of five categories summarized in Figure 1. These were used to help differentiate among systems as opposed to a single pass or fail criteria. Examples of ratings 2 through 5 are shown in Figure 2.

Testing impact resistance

TPO membranes in smooth, fleece-back configurations were used throughout the testing. Substrates were glass mat-faced gypsum board, polyisocyanurate foam insulation (ASTM C1289, Type II, Class 1, Grade 2 having a compressive strength > 20 psi) and high-density polyisocyanurate cover board (ASTM C1289, Type II, Class 4, Grade 1 having a compressive strength > 80 psi).

Figure 2 (pictured clockwise from upper left): Examples of ratings 2 through 5 from the impact of a 2-inch ice ball on a TPO membrane |

Fully adhered systems were studied using water-based, solvent-based and two-part low-rise urethane foam adhesives. In addition, a self-adhering TPO membrane was evaluated. The manufacturer's adhesive application rates were used throughout. In the case of the low-rise urethane foam, ribbons were applied at 4 inches on center, and full adhesive coverage was achieved by applying light pressure with a roller across the membrane.

Impact effects on membrane

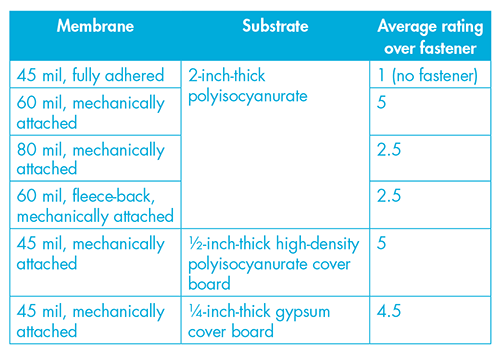

When impacted above a metal fastener (always used with an appropriate plate), TPO membranes of any thickness always failed with a rating of 3 or worse (see Figure 2). This was the case regardless of substrate as shown in Figure 3. As indicated by the fully adhered 45-mil-thick membrane, all membranes passed in the sheet's field, providing there wasn't an insulation fastener underneath the point of impact. This clearly suggests fully adhered methods of adhesion for a membrane and top layer of insulation or cover board without through fastening should be considered when installing single-ply roof systems in high-frequency hail areas.

Figure 3: Impact ratings for TPO membrane over various substrates (1 indicates no damage; 5 is worst damage) |

Impact effects on substrate

The impact effects on substrates also were tested without a cover board and with a cover board.

Without cover board

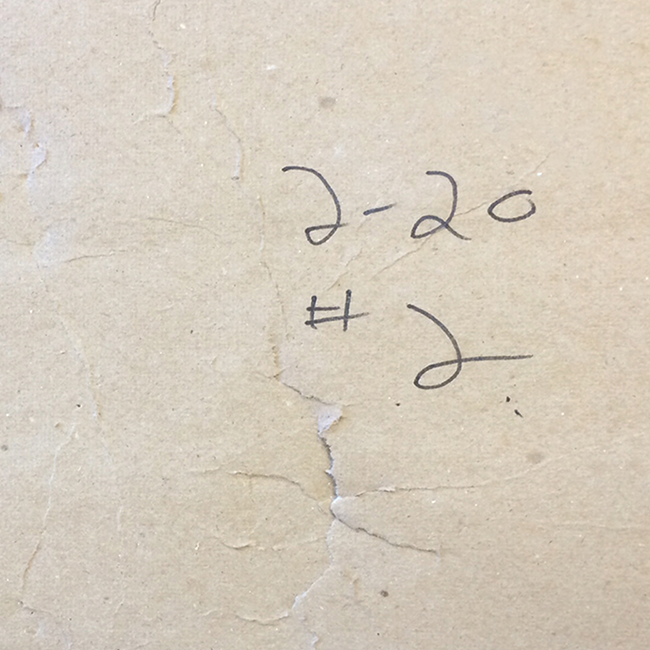

Testing of TPO membranes over polyisocyanurate insulation showed the foam core suffered significant damage, including extensive breakage of the paper facer and crushing of the underlying foam to a depth of about 1/2 of an inch. An example is shown in Figure 4.

Figure 4: Polyisocyanurate covered with a mechanically attached 60-mil-thick TPO membrane shows damage after two ice ball impacts |

Damage to the polyisocyanurate in the field area occurred regardless of membrane thickness or whether a fleece membrane backing was used. In each case, a significant, deep dimple was retained in the membrane, supporting many field observations.

With cover board

To compare gypsum and high-density polyisocyanurate cover boards, a range of fully adhered systems was tested. Figure 5 compares each component's impact performance. A cover board's internal condition only was tested in cases where there was no obvious failure of the cover board facer, such as cracking. An important finding is a cover board can appear to be undamaged by virtue of the facer being intact, but the core can be significantly damaged.

Figure 5: Ice ball impact evaluation matrix for fully adhered TPO membrane systems. Scores of 1, 3 or 5 indicate passing (no damage), borderline passing or bad performance, respectively. |

When a membrane over gypsum cover board was impacted, substantial damage to the cover board's top and underside was seen (see Figure 6).

When we cut into the glass mat-faced gypsum board, the board's gypsum core was found to be totally crushed from top to bottom and powdery. The damage also was transferred to the polyisocyanurate insulation underneath, splitting the foam insulation's top facer.

Figure 6: Gypsum cover board damage on the top and underside |

Damage to the gypsum cover board and underlying polyisocyanurate insulation was so extensive it calls into question the viability of such a system for long-term protection in high-frequency hail regions. In places subjected to direct hail hits, after some number of such impacts, the membrane essentially could be unsupported.

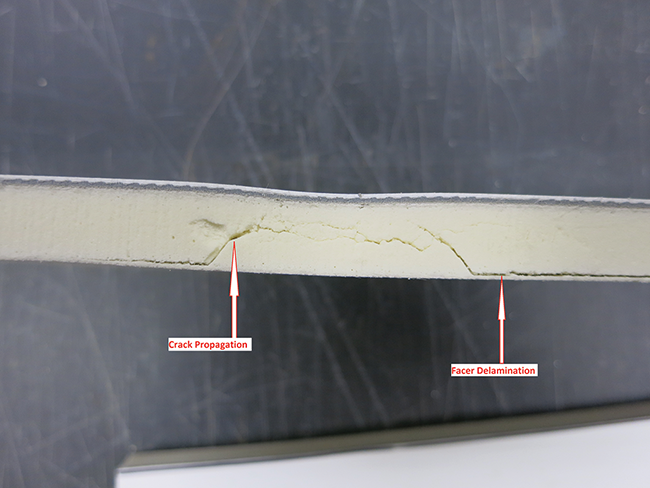

Regarding high-density polyisocyanurate cover board under smooth TPO, minimal facer damage was observed following ice ball impact. However, the high-density foam core showed some delamination and cracking as indicated in Figure 7.

The presence of fleece membrane backing significantly reduced damage to the high-density polyisocyanurate cover boards, and 80-mil-thick, fleece-back TPO showed no damage. No differences were seen between water- and solvent-based adhesives, but low-rise foam provided a slight improvement.

Figure 7: High-density polyisocyanurate cover board cross-section after two ice ball impacts. The system was a 60-mil-thick, mechanically attached TPO membrane over a cover board and 2-inch polyisocyanurate insulation. |

Conclusions

Ice ball resistance of single-ply membranes is a result of a roof system's overall design and selection of individual components. Although membrane and substrate selection are important, an entire system must be considered.

In terms of membrane impact resistance, all new membranes passed the 2-inch diameter ice ball test when impacted in the field regardless of substrate. However, none passed when impacted directly over a metal fastener.

Clearly, for best ice ball impact resistance when looking only at membrane damage, fully adhered systems should be considered.

When the definition of impact failure is extended to include substrate damage, the following can be concluded:

- Standard, > 20 psi compressive strength, polyisocyanurate insulation is readily crushed to a depth of about 1/2 of an inch from an impact by a 2-inch ice ball.

- Gypsum cover board suffers a large amount of damage; facers suffer large cracks and the board core shatters.

- In general, high-density polyisocyanurate appears to be more resilient than glass mat-faced gypsum board. Essentially no damage was incurred during the ice ball impact test with the following combinations installed over high-density polyisocyanurate:

-

- 60-mil-thick, 3 1/2-ounce fleece-back membrane and two-part foam adhesive

- 60-mil-thick, 5 1/2-ounce or heavier fleece-back membrane with any adhesive type

- 80-mil-thick, 3 1/2-ounce fleece-back membrane with any adhesive

When considering ice ball impact resistance, it's important to look at an entire roof system and not just the membrane or substrate.

To best protect insulation, a high-performance cover board such as high-density polyisocyanurate can provide good system performance, as well. Remember—don't just pick the best product, pick the best roof system.

Sarang Bhawalkar, Ph.D., is senior research associate for GAF, Parsippany, N.J.; Thomas J. Taylor, Ph.D., is executive director of single-ply systems product development for GAF; and Tammy Yang, Ph.D., is senior principal scientist at GAF.

For articles related to this topic, see:

"Holy hail! (part one)," May 2009 issue

"Holy hail! (part two)," June 2009 issue

"Standing up to hail," June 2007 issue